Genetically engineered reduced-lignin alfalfa has been recognized as offering more flexibility in cutting schedules, helping farmers achieve improved forage quality or greater yield potential when compared to conventional alfalfa varieties at the same stage of maturity.

Delaying harvest a week to 10 days to obtain higher tonnage without sacrificing forage quality is an attractive proposition. Agronomic benefits such as potentially reducing harvest cost and increasing stand persistence are advantages of this new technology.

Dan Undersander, extension agronomist at the University of Wisconsin, says reduced-lignin alfalfa has great potential but will require farmers to adopt new management systems to reap the benefits. Seeding practices and harvest timing can both greatly influence success.

In seeding years, growers have been advised to harvest alfalfa about 60 days after planting, and this is the same for reduced-lignin varieties also, says Undersander. After the initial cutting, reduced-lignin alfalfas can be harvested at 28-day intervals for higher quality or at 35 days to obtain similar quality as conventional alfalfas with higher yield.

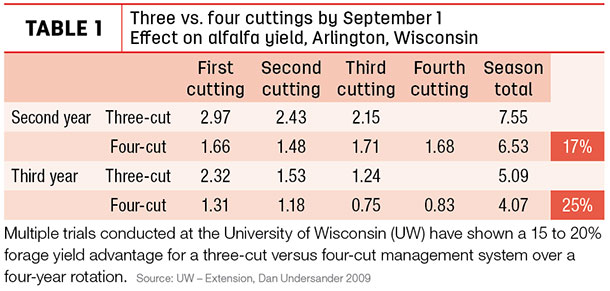

Reducing the number of cuttings each year provides significant agronomic advantages to the life of the alfalfa stand. Table 1 illustrates one of the advantages of a three-cut versus a four-cut harvest system.

Growers see great promise in having genetically engineered reduced-lignin alfalfas as part of their management strategies. This new technology comes with a higher up-front cost than conventional alfalfas but offers greater agronomic benefits such as delayed harvest and higher yield potential. Here are a few of their developing stories based on initial field trials.

Josh Waddell

Apple Shamrock Farms

Townville, Pennsylvania

Waddell, who milks 1,000 cows on his dairy operation in northwestern Pennsylvania, has historically grown orchardgrass to use as feed. The extra 10-day cutting window offered by reduced-lignin alfalfa appealed to him.

“Our cows were stuck at consuming 92 pounds of feed per day as-fed,” he says. “Our goal is to approach 100 pounds of feed per cow per day for our herd. I started researching reduced-lignin alfalfa and discovered that, between the cutting window and the technology, the benefits stood to outweigh the cost.”

Waddell carefully prepared for planting his reduced-lignin alfalfa fields by improving the soil fertility – achieving a pH between 6 and 8, applying phosphorus and potassium, and tissue sampling at every cutting. Waddell says, “We stepped up our game to focus on creating a high-value crop.”

The orchardgrass Waddell had traditionally grown fell into an 18 to 19 percent protein level with relative feed quality (RFQ) of 150. With the reduced-lignin alfalfa variety he is currently growing, he’s been able to hit 22 to 23 percent protein with a 176 RFQ.

“The reduced-lignin alfalfa feeds really well,” he says. “We were able to reduce a pound of protein blend in our grain mix per cow per day and increase milk production by about 2½ pounds after feeding reduced-lignin alfalfa for a month-and-a-half. My goal is to consistently get RFQ between 170 and 190, and protein at 22 percent plus.”

In the long term, Waddell wants to meet half of his haylage needs with orchardgrass and half with reduced-lignin alfalfa, feeding the reduced-lignin to “fresh and high-end cows that can really benefit from the product,” he says. “We’re going to use reduced-lignin alfalfa as another tool in the toolbox to complement the forage for our dairy cows.”

Steve Landwehr

Alpha Foods LLP

Litchfield, Minnesota

Landwehr and his partners operate a 1,400-cow dairy in the central part of the state. His dairy adviser approached him about doing an alfalfa trial. “We asked a couple of our custom hay growers to plant about 330 acres of reduced-lignin alfalfa with about another 240 acres of conventional,” says Landwehr.

Landwehr tries to keep RFQ for his herd in the 180 to 190 range. However, the overall average through the years has been 135 or 140, up to 210 or 220. “We’d like to tighten that up a bit between harvests,” he says.

“That’s what the reduced-lignin variety is supposed to do – give us more time to complete harvest in a timely manner and not see a big drop-off in that last week of growth.”

Although Landwehr had not yet made his final reduced-lignin alfalfa cutting, he has had several fresh-cut samples tested, most of which have been running between 180 and 220.

“As reduced-lignin technology evolves, and we learn more about it, we’ll see whether we can go from a four-cut to a three-cut system and maintain the same quality and tonnage – and perhaps minimize some of our harvesting costs,” he says. “We’re trying to reduce our input costs on our feed, and reduced-lignin technology is one way we can do that.”

Brian Larson

Cottonwood Dairy

South Wayne, Wisconsin

“Alfalfa quality is of the utmost importance because we have highly erodible soil types in this area,” says Larson, who milks 1,500 cows on his southwestern Wisconsin operation. “We need alfalfa rotation to keep our land in good shape. We can’t grow continuous corn here.”

Larson seeded a little over 300 acres of alfalfa this year, with slightly more than 100 acres in reduced-lignin alfalfa.

“We don’t know yet how the reduced-lignin alfalfa is going to feed,” says Larson. “But it was consistently 30 points higher in relative feed value than conventional alfalfa. That’s a really big number, and it was very encouraging.”

In 2017, Larson intends to plant reduced-lignin alfalfa on his new alfalfa seeding areas, which constitute about one-quarter of his 1,250 alfalfa acres.

Larson says that his agronomist, as well as Dan Undersander, helped ensure good management practices were in place. “With the higher cost of reduced-lignin alfalfa seed, it’s more important to pay attention to seedbed preparation,” he notes.

“If we can get the kind of quality we’re looking at out of reduced-lignin alfalfa, it’ll be money well spent. We’re excited to see the results.” ![]()

Due to factors outside of WinField United’s control, such as weather, crop production patterns, and other factors, results to be obtained, including but not limited to yields or financial performance, cannot be predicted or guaranteed by WinField United.

Results are based upon controlled tests, field trials and public trials. Results may vary.

PHOTO: Growers rate reduced-lignin alfalfa. Photo by Mike Dixon.