Bacterial silage inoculants are critical to preventing excessive nutrient loss and to enhancing fermentation success. Over the past 30 years, microbiologists have developed the scientific capabilities to screen, quantify and evaluate bacterial strain combinations. This scientific capability has led to a continuous improvement of bacterial inoculants designed for the world’s major silage.

The false economy of cheap knockoffs

Producers frequently choose to skimp on inoculant purchases, because the technology is not well understood. And since inoculants are unregulated in the U.S., many ineffective products are sold under the guise of inoculants.

Scientists now understand how bacterial inoculants work and can prove performance through research. However, formulating a suitable combination of bacterial strains for maximum performance requires time and money. The reward is better forage with significantly less loss due to fermentation or aerobic stability.

Today’s “super bacteria” inoculants are designed to perform in a variety of fermentative environments. These modern inoculants are capable of delivering more silage protection by efficiently preserving and enhancing silage quality during all phases of fermentation and feedout.

In the world of bacterial inoculants, two key families of bacteria are used for silage crops, namely Lactobacillus plantarum and Lactobacillus buchneri. Extreme differences exist between families and within families. These differences influence fermentation success and the ability to perform well under different environments.

It’s best to do one thing really, really well

The initial process of fermentation is both a biological and chemical reaction. If you can accomplish this process really, really well, you will have well-preserved silage with the least amount of loss possible.

One of the most fundamental chemical activities that occurs is the production of acids that reduce silage pH. Lowering silage pH together with elimination of oxygen prevents spoilage organisms from growing and stabilizes silage.

Production of silage acids is accomplished when homofermentative bacteria (L. plantarum) convert sugars (energy) to lactic acid. Naturally occurring bacteria are typically very inefficient during this process and consume more energy than is required of the most efficient L. plantarum strains.

Bacterial inoculants are designed to work best with specific crops. Microbiologists discovered that some strains of bacteria were better for corn, while others were better for alfalfa, and still others worked better for grasses. Matching strain and crop helps drop the pH level more quickly and allows us to preserve dry matter more efficiently than before.

Faster is better

From the first minutes of ensiling forage, it’s a speed race to dominate the existing epiphytes and get your preferred bacteria to grow. Without the addition of a bacterial inoculant designed to control the initial fermentation process, only naturally occurring epiphytes will be available to produce acids and lower pH. While the result may be an ensiled crop, the cost of allowing the natural bacteria to ferment the crop can be extremely high. If this initial phase doesn’t go well, the result can be poor fermentation with undesirable end products.

Fast acting, highly efficient strains of bacteria help to reduce the “energy cost” of preservation. This energy savings directly translates to reduced shrink and allows for greater dry matter recovery of 3-5 percent during the initial phase of fermentation.

A great start and a better ending

The ability to deliver fresh feed from the silo to livestock is critical. When silage is re-exposed to oxygen at feedout time, the aerobic organisms present in the silage begin to grow again. These organisms are typically yeasts and mold-producing fungi. When they grow, they consume energy, and this can result in heating and is costly both in terms of the quantity and quality of fed silage.

In fact, one of the primary energy sources for growth of yeasts and fungi is lactic acid. As these organisms consume lactic acid, pH rises again and even more damage can occur to silage, resulting in moldy feed with lower energy.

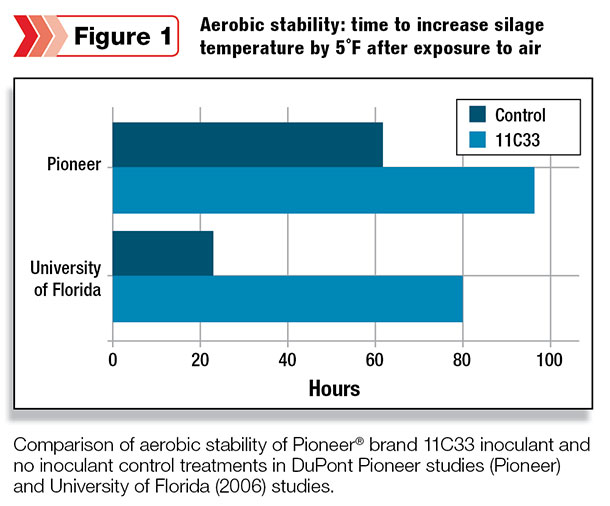

In the 1990s, researchers identified strains of Lactobacillus buchneri (L. buchneri) that can be combined with crop-specific, fermentation-controlling bacteria that dramatically improves aerobic stability (bunklife). These inoculants provide, on average, 100 or more hours of silage stability (time before heating occurs) than untreated silages. L. buchneri is a heterofermentative species and produces acetic acid as an end product. Acetic acid is weaker than lactic acid, so it will lower the pH at a slower rate and the final pH is typically slightly higher. However, acetic acid is a very good yeast inhibitor and reduces heating and the resulting losses during feedout. By preventing yeast formation, the resulting feed is more consistent and stable while maintaining high forage quality.

L. buchneri is a heterofermentative species and produces acetic acid as an end product. Acetic acid is weaker than lactic acid, so it will lower the pH at a slower rate and the final pH is typically slightly higher. However, acetic acid is a very good yeast inhibitor and reduces heating and the resulting losses during feedout. By preventing yeast formation, the resulting feed is more consistent and stable while maintaining high forage quality.

Super Bacteria – A new era in inoculant technology

With the recent introduction of Fiber Technology, the era of using your silage pile as an incubator for specific end products has arrived. Researchers discovered a unique strain of L. buchneri producing two key enzymes (ferulate and acetyl esterase) that improve silage quality, especially fiber digestibility.

Enzymes produced by these unique L. buchneri strains help separate plant lignin from cellulose and hemicellulose, allowing ruminant animals to take advantage of lignin-bound energy. Higher energy from fiber can result in feed savings or increased productivity, along with the ability to feed high forage diets.

Great silage experiences depend on several key factors, including proper silage moisture and oxygen elimination. Proven silage inoculants can then be used to drive efficient reduction of silage pH and aerobic stability at feedout. The end result is improved animal performance and feed cost savings. FG

Dan Wiersma is livestock information specialist for DuPont Pioneer.

PHOTO

Courtesy of Dan Wiersma.