Both types of fencing systems include a permanent boundary fence consisting of woven or barbed wire or electrified, high-tensile smooth wire to ensure livestock are restrained on the ranch and excluded from areas such as roads and private property.

Fence placement and layout

Proper fencing is usually a major investment. Therefore, plan fencing layout carefully to save time and money. One of the benefits of a well-designed fencing system is that it can improve grazing efficiency.

In continuous grazing, livestock tend to graze the most palatable plants first and leave mature plants until last. Forage selectivity by livestock often leads to concentrated and nonuniform manure distribution in the pasture.

One of the first management considerations in designing grazing systems is selection and installation of the proper fencing system.

Give priority to well-built perimeter fences and fences along roads or other areas from which livestock must be excluded, such as cropland.

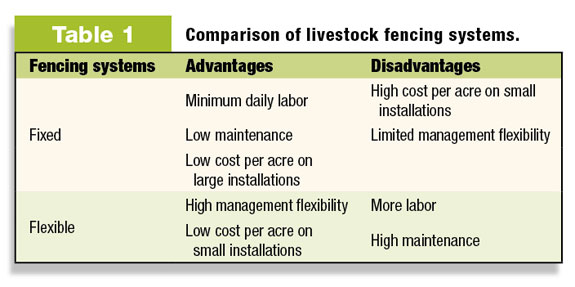

An effective fencing layout for rotational stocking includes a combination of permanent and temporary fences (Figure 1).

The combination will provide both perimeter security and flexibility for adjusting paddock size with livestock daily nutritional needs and forage availability.

The ideal number of fenced paddocks depends on forage species and productivity, performance goals, grazing pressure, rate of plant recovery, economic capability, and livestock characteristics such as herd size, animal weights, and production levels.

Size paddocks to provide consistent days of grazing. A 30- to 50-day rotation is very common and requires about 10 paddocks if cattle are moved at least once a week.

During the spring, when forages grow rapidly and may grow to excess, a quick rotation of about 20 days may be needed to keep plants in a vegetative stage.

A faster rotation means larger paddock areas are grazed for shorter periods of time with shorter intervals between grazing. Four paddocks in a 20-day rotation means moving animals every 5 days.

On the other hand, a 45-day rotation, appropriate during slow winter growth or drought conditions, means longer periods between grazing, a restricted forage diet, and longer periods spent in each paddock.

It may be necessary to divide the ranch up into as many as 20 paddocks. With this number of paddocks, gates can be opened or animals moved more often during a quick rotation; temporary electric fencing can further split paddocks during a slow rotation; or paddocks can be cut out of the rotation to produce hay.

To develop proper paddock layout and to estimate how much fencing will be necessary, consult aerial photos available through the National Resource Conservation Service (NRCS) or Farm Service Agency (FSA). A soil survey will also aid in dividing the paddocks for similar production capabilities. Plan for straight fences; they are more economical and easier to lay out and construct.

The shape of the fenced pasture makes a big difference in the length of fence needed to enclose the pasture. Paddocks should be fairly square, minimizing soil variation and following landscape changes.

A perfect square is not always possible, as access to water, shade, livestock- handling facilities, and the natural lay of the land must be considered. Square paddocks usually require the minimum amount of fencing and reduce distance to water sources.

Rectangular paddocks should be no more than four times as long as they are wide. Pie-shaped fencing designs with a central water source can lead to mud holes where livestock congregate at water sources.

Also, following land contours is much more difficult with pie shapes. Paddocks can be subdivided with temporary fences to change grazing periods and to adjust for seasonal changes in forage availability.

Calculate the length of fencing needed for different fencing layouts. This exercise will help identify the most efficient layout and estimate the amount of supplies necessary.

Types of wire

Three main types of wire are used in permanent livestock fencing: barbed wire, woven wire, and high-tensile wire.

• Barbed wire fences contain strands of horizontal wires twisted together with barbs spaced every 4 to 5 inches.

• Woven wire fences are smooth horizontal and vertical wires made of mild steel. Many producers use them, but they typically are more expensive and may be less effective than high-tensile electric fences.

• High-tensile wire is used for both nonelectric and electric fencing. It is lighter than mild steel and has greater elastic capacity. High-tensile wire costing about the same amount as mild steel is two and a half times stronger than mild steel.

For example, when a corner post or H brace moves ½-inch, a mild steel wire such as barbed wire loses over 20 percent of its original strain, but high-tensile wire loses only about 10 percent.

High-tensile fences can be electric or nonelectric. High-tensile, nonelectric fences are desirable because they can withstand livestock contact and low temperatures without losing elasticity.

The wire used in this type of fencing is usually 11- to 14-gauge wire with a tensile strength of 170,000 to 200,000 pounds per square inch and a breaking strength of 1,800 pounds.

Post placement

Setting posts correctly is one of the most important factors in fence strength. The first consideration is setting the post at the correct depth.

The proper depth depends on the diameter of the post and soil type. Generally, in medium to heavy clay soils, a post should be placed at a depth equal to ten times its diameter.

In sandier soils, the depth should be fifteen times the diameter. These depths ensure the post would break before it would uproot.

If posts are too short or it is impossible to dig a deep enough hole, a “foot” may be used to anchor the post. A foot can be constructed from a 1-foot piece of four-by-four nailed or wired to the bottom of the post to form a “T”.

The “T” helps hold the post in the ground. A foot may also be necessary if there are dips or angles greater than 10º in the fence line.

Post spacing varies with the fence type (i.e., electric versus conventional) and the contour of the land. On a flat piece of ground with 2- or 3-wire electric fencing, posts can be spaced over 1000 feet apart as long as T-posts or hardwood posts are placed every 40 to 50 feet.

Where the land has dips and angles, place posts at the top and bottom of the dip to make sure the fence follows the contour of the land. FG

Click here to email an editor for references which have been omitted due to space.

—Excerpts from Mississippi State University Extension

Rocky Lemus

Extension Forage Specialist

MIssissippi State Univeristy