Hay test results are not absolute values. Let’s discuss sources of variation in lab test results. I propose some recommendations for resolving differences in results.

Sampling variation

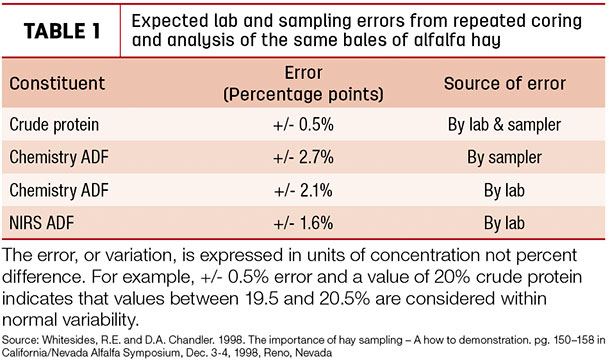

The largest source of variation in quality testing is the process of adequately sampling a lot of hay. Results of a Utah State University study (Table 1) show sampling is the largest source of error.

This is a daunting task when you consider the amount of forage analyzed may be 1 to 50 grams, and it should represent hundreds of tons of hay or forage. Research on large and small bales has shown 20 cores (each from a different bale) will allow good representation of the entire lot of hay.

A good average-size sample should weigh from a third- to a half-pound (150 to 200 grams).

Your lab should grind the entire sample. It is difficult to split a sample without grinding it first. If you wish to send subsamples as similar as possible to different labs, ask for return of your ground sample.

Laboratory variation

The proficiency of a laboratory depends on the methods used and the precision of laboratory techniques. The National Forage Testing Association (NFTA) certifies the proficiency of laboratories for accuracy in testing hay and corn silage for dry matter, crude protein, acid detergent fiber and neutral detergent fiber.

Following the recommended protocol will minimize error in tests. However, growers, brokers and livestock producers need to be aware of the limits of accuracy of forage quality tests.

Unfortunately, laboratory error is added to sampling error in the test analysis. Normally, there might be plus or minus 5 percent variation in results, (e.g., plus or minus 1.5 percent acid detergent fiber or plus or minus 8 relative feed quality or RFQ).

Unfortunately, laboratory error is added to sampling error in the test analysis. Normally, there might be plus or minus 5 percent variation in results, (e.g., plus or minus 1.5 percent acid detergent fiber or plus or minus 8 relative feed quality or RFQ).

Usually a test of 31.5 percent acid detergent fiber is not different than 30 percent acid detergent fiber, and neither is a test of 172 RFQ different than 180. Proper training and conducting of sampling and laboratory analyses will minimize errors in predicting forage quality but will not eliminate them.

Variation of analysis from one lab to another is usually greater than variation within a lab. So it is recommended to choose a certified lab and stay with it to get consistent results. No one benefits from inaccurate forage quality testing.

Forage quality is a multi-faceted system, the quality values are not absolute, and analysis is not adequately described by any one variable. Selecting a NFTA-certified lab should minimize variability in analyses. I suggest the lab also be capable of reporting neutral detergent fiber digestibility, total digestible nutrients calculated as the sum of digestible components and RFQ, which is a better quality index than relative feed value (RFV).

Storage conditions and time change forage quality

Forage quality declines with time, even if optimally stored, due to forage degradation. A sample taken from the same lot of hay the day it is baled is expected to have lower fiber values than a sample taken from the same lot six months later. Therefore, sample as close to the time of sale or utilization of the lot of hay as practical.

Choosing a forage testing lab

Most forage testing laboratories attempt to provide accurate and repeatable results to their clients. In the long term, their reputation and success depends on accurately predicting the feeding value of the forage. Price and marketability of forage is often based on the laboratory test.

The American Forage and Grassland Council, the National Hay Association and forage testing laboratories combined to form NFTA in 1984 to improve the accuracy of forage testing and build grower and consumer confidence.

Since participation in the certification program is voluntary, not all hay test laboratories are involved. This certification provides the producer and consumer confidence the laboratory is proficient at certain forage quality tests, has a quality control procedure, and they know their accuracy. We recommend only using a laboratory that is NFTA certified.

How are labs graded?

Laboratories are evaluated and graded six times every year. Unknown samples, including four alfalfa samples (one of which contains approximately 20 percent grass) and one sample each of corn silage and grass, are sent to each laboratory, which analyzes them using standard accepted techniques. I recommend a next step that should be implemented is to provide “blind samples” to the labs in a way that they do not know laboratories are being evaluated.

Chemistry or near-infrared reflectance spectroscopy

Currently accepted techniques of forage analysis include traditional wet chemistry and near-infrared reflectance spectroscopy (NIRS), which is a technique that uses light reflectance, is quicker and less expensive than laboratory chemistry and gives equivalent results.

Some laboratories will use only one technique, while others use both. Those laboratories providing test results within the specified limits are certified. Certified laboratories located in selected states are listed online (foragetesting.org).

Different results: Now what?

When two labs produce different results for the same hay lot, communicate with all parties. Do something positive to resolve the situation. Ask both labs to rerun their sample and to send a proper subsample to the other lab. If a lab refuses to do this, consider using another NFTA-certified lab.

Understand, labs cannot keep samples indefinitely but should for 30 days. If the results still vary by more than a typical margin of error, take a joint core sampling of the lot, divide the ground sample using a laboratory sample splitter and have each lab analyze the samples and compare results. Then it seems fair to average the test parameters of interest and negotiate a price.

I have heard of hay buyers insisting on only using a lab they prefer and refusing to consider other certified lab results. Unfortunately, sometimes milk production does not reflect the forage test results. This may cause a hay buyer to become more conservative and discount the quality parameters or price because of the uncertainty.

However, I would ask: What proportion of the ration does their forage comprise? If it is only 7 percent of a TMR, I would question if 10 RFQ points makes a significant difference.

There are philosophical differences in whether the data used in prediction formulas should be locally or globally based. A locally based formula may be more accurate for local environmental and management factors.

However, a globally based formula will better represent forage quality across the nation and overseas, as our exports are increasing. Without some standardization, results could not be compared at all, thus the development of NFTA.

Summary

There is an inherent challenge to predict complex biological processes with a few chemical tests or estimates from light reflection. Additionally, the mass of forage in a lot of hay is large, making accurate sampling a daunting process.

Although significant progress has been made, we are still a long way from accurately predicting forage quality, and thus value, with adequate confidence. Information, communication and negotiation are the keys to agreeing on a fair price for the producer and consumer. ![]()

PHOTO 1: Glenn Shewmaker, University of Idaho forage specialist, uses a manual hay probe to take a sample for analysis to send to a certified laboratory.

PHOTO 2: The tip on this hay probe is tapered to allow easy drop of the sample into the collection bag. It also has a tip that can be sharpened and takes a clean-cut sample. Photos by Lynn Jaynes.

-

Glenn Shewmaker

- Forage Extension Specialist

- University of Idaho

- Email Glenn Shewmaker

Hay probes and techniques

The choice of either power-driven or hand-powered probes can be used in an integrated sampling program, which includes taking at least 20 cores, sampling at 90 degrees to the butt ends of bales, sampling about 18 inches into the bale and proper sample handling.

There are a wide range of acceptable coring devices, each with advantages and disadvantages. Probes should satisfy a number of criteria: They must fairly represent the leaf-to-stem ratio of the bales, they should sample deeply enough to represent the variation within bales, the tips should be kept sharp, and tips are recommended to be at 90 degrees to the shaft (not cut at an angle).

- No part of the sample (e.g., leaves or stems) should be lost when the probe is withdrawn from the bale (as it is with open augers).

- Diameter should be between 3/8- and 5/8-inch. An extremely small-diameter coring device may not cut or represent the leaf-to-stem ratio properly, and a very large-diameter probe may obtain a too-large sample, which is difficult for labs to grind properly.

- Length should probe to 14 to 24 inches in the butt ends of the bale. On large bales, some studies have shown it is not necessary to sample to a greater depth, though further studies are being conducted.

Long probes (greater than 24 inches) or wide-diameter probes have the disadvantage that very large samples are generated, which in itself is not a problem, but many labs as a result will not grind the entire sample, which defeats the purpose of careful sampling.

The purpose of good technique is to develop a sample of about a half-pound with at least 20 probed cores.

—foragetesting.org