The price tags on agricultural goods, along with other day-to-day necessities, are changing by the week. In the last few months, we have seen huge spikes in the markets, both up and down, as our needed suppliers and purchasers deal with shortages.

Nobody knows about variability and unpredictability better than a farmer – just ask them about the stress of making hay. Hay is a very versatile feedstuff, for every animal from dairy cows to rabbits, and most farm animals can utilize hay in their everyday diets.

Inputs, freight, land and, in some places, droughts have all driven up hay in price, so for these reasons and others, hay is an investment. Investments require planning and research to ensure that what is being done can help improve the return on your money. If we could order weather like we do food from a restaurant menu, that might solve over half of our concerns – but management decisions, such as those related to fertilization and storage, play a significant role in hay quality.

Many hay growers are asking themselves one question: Does it pay to fertilize my hay this year? Nitrogen, phosphorus and potassium are currently two to three times more costly per ton than they have been in the past, so the answer is not simple.

First and foremost, it is important to know the current nutrient levels of your soil. Although most fields have different soil types, a general idea of the current fertility as provided by soil sampling gives you a starting point. Next, you can do a small amount of research and find nutrient removal tables for hay type and tonnage from most universities. With those nutrient tables and current soil samples, you can approximate the nutrient usage from one year of production. Every farm has a fertilizer budget, and included below is a list of priorities when considering your nutrient placement:

1. Recently planted: These fields have the strongest plant count with the highest level of plant health and vigor. These fields are the highest-producing and require more nutrients. These plants also respond with greater efficiency to added nutrients.

2. Grassy fields: Legumes are much better at fixing their own nitrogen for plant needs. Grass plants respond quickly and efficiently to nitrogen application.

3. Low-fertility fields: If you have livestock, these are probably the fields that are the farthest away. Closer fields tend to get more manure and have a higher level of fertility. Strongly consider hauling manure to farther fields or spending more of the fertilizer budget on outlying ground.

Given current synthetic fertilizer prices, manure has become increasingly more valuable and should also be tested for nutrient concentrations and placed strategically. Manure can take time to load, transport and apply, so most of it travels as short a distance as possible. Besides catering to farther pieces of land, consider better management when applying with things like the variable rate, incorporation and soil injection to allow those home-grown nutrients to cover as many acres as possible.

You have fertilized, grown and harvested the hay, and now you need to put the investment in the bank. Optimizing storage means minimizing shrink and spoilage after baling until sale or feeding. Losses due to improper storage can reach up to 50%, so there is a laundry list of things we can do to retain as much good hay as possible.

Every bale goes through a heating process, during which natural plant processes and microbes like yeast and mold growth consume sugars, starch and oxygen. The degree of heating depends on the moisture level and density of the bale, so the more oxygen and moisture present, the higher the temperature. If we cannot get enough moisture out of the hay before baling, wrapping is required to make baleage; otherwise, heating will burn up the entire bale. If the bale moisture is under 25%, we can treat it as dry hay and store it accordingly.

Storing bales can consist of one of two options: inside or outside storage. Additionally, the quality of the outside elements and their effects on spoilage varies from region to region and based on the weather patterns.

Inside storage

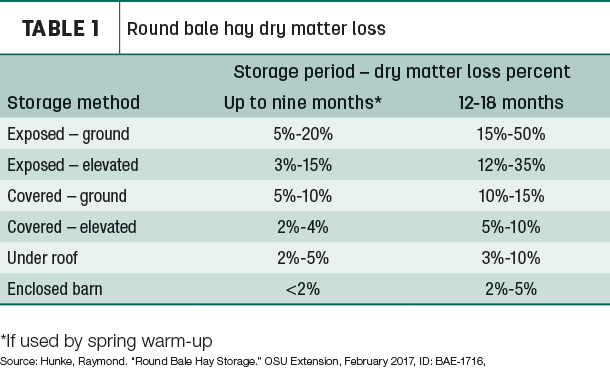

As we would expect, the dry matter loss from under-roof or shed storage is significantly less than when raw hay is exposed to the elements outside (Table 1).

When protected from rain and groundwater, there is very little to influence the quality of the bales. Shed space is very expensive, though – and only if you are in a region with lots of rain does it pay to use this storage method.

The process of sweating and breathing bales becomes a larger factor when storing hay inside. All bales go through a heating process, during which they sweat out any remaining moisture as they stabilize. If this is not done properly, it can leave moisture within and in between the bales, promoting mold growth. Bales should be left unstacked with room for air flow around them for three weeks prior to stacking in their permanent place inside. If possible, it is also a good practice to allow for 2 to 3 feet of head space at the ceiling for air flow in and out of the hay shed.

Outside storage

Storage outdoors has good and bad qualities:

Positive

- Space is unlimited

- Less hauling (if stored in the field)

- Shorter sweat period

- No building cost or maintenance

- More shed space for equipment

Negative

- Increased spoilage (two to 10 times more than roof storage)

- Moisture-wicking bottoms

- Plastic and wrapping purchase

- Plastic disposal

- Separated from place of feeding

- Subject to wildlife

- More acres needed to make up for lost hay

Placing round or square bales on an elevated base, rowing north to south and/or stacking can all help reduce outdoor losses. Inline and individual wrappers have become increasingly popular, and wrapping dry hay with three layers can have a huge impact on sunlight degradation and rain-proofing.

Regardless of whether hay is stored inside or outside, the packing density is crucial for structural support and helps maintain the hay’s integrity from hauling, stacking, wrapping and feeding. Dry matter loss does not discriminate between low- and high-quality hay and will commonly create losses of $25 to $115 per ton. Even though this year is not going to be a builder of fertility in the field, bought or current soil fertility, along with diesel fuel, equipment wear and time, will go into each bale.

Consider using a preservative to maintain those highly valuable sugars and protein in hay and silages to make these high feed costs a little easier to manage.