Many farmers have harvested alfalfa and then found it did not have the expected relative forage quality (RFQ). A new forage analysis, leaf percentage, may help determine the cause of the problem. Assuming that alfalfa is harvested at the correct maturity, the common reason for low RFQ is leaf loss before or during harvest.

This new analysis is an estimate of leaf percentage of pure alfalfa hay, haylage or fresh forage. Originally developed by Forage Genetics International Research (David Weakley and Charles Rodgers), it can be a valuable guide to better manage alfalfa growth and harvesting efficiency.

The basic concept is that alfalfa is about 50% leaves and 50% stems, on a dry matter basis, at mid-bud to early flower. Leaves are about 30% crude protein (CP) and 500 to 550 RFQ while stems are about 6% to 8% protein and 70 to 80 RFQ. Thus, the loss of leaves is both a yield loss and a forage quality loss.

At bud stage and later, alfalfa may lose leaves due to diseases. One can determine if this is happening by examining the leaves of alfalfa prior to harvest and looking for yellowed leaves and leaves fallen to the ground. If extensive, a foliar fungicide may have been worthwhile at the initial stages of regrowth in the spring or after cutting and should be considered for at least first and second growth cycles next year.

However, the largest leaf loss often occurs during harvest, and that situation reduces both yield and forage quality. Most forage crops are around 75% to 80% moisture when cut then dried down to 14% to 18% to bale. The drier the hay, the greater risk leaf loss is during the baling process. But if you harvest your crop at moisture levels much higher than those ideal ranges, you run the risk of molding and spoilage after baling.

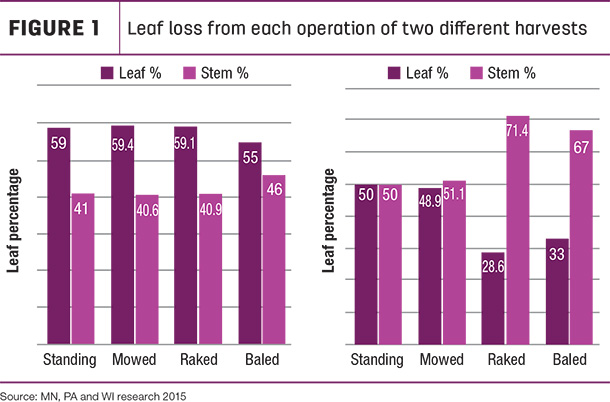

Figure 1 shows differences in leaf loss is due largely to operator management.

A small amount of leaf loss will occur during mowing. This is true for mowing with either sickle bar or rotary mowers with chevron rubber, urethane or steel conditioner rolls. Roller conditioners will result in about 1% leaf loss and flail conditioners will cause about 4% to 6% leaf loss for alfalfa.

In Figure 1 on the left, hay was raked/merged and baled with minimal leaf loss. This demonstrates that losses can be minimal with appropriate management.

On the other hand, in the graph on the right, leaf loss was 20% during raking/merging. This is probably more common than many growers realize. Leaves on the surface of a swath or windrow get brittle and shatter easily.

Consider that at $210 per ton of hay and $1 per point of relative feed value (RFV) for a 2-ton-per-acre yield, each 1% leaf loss results in a $14-per-acre yield and quality loss. Thus, the example in Figure 1 on the right was losing $239 per acre from the single cutting.

Properly operated, rotary rakes or mergers tend to have the lowest leaf loss of the different rake types. However, with both, the tendency has been to drive faster to reduce raking time. A rotary rake should be operated such that the rotary speed is in sync with the ground speed of the tractor. Similarly, the merger should be operated so that the pickup is in sync with the ground speed. Failure to do so results in the swath being torn apart and leaves stripped off. Some mergers now have a screen over the pickup. This reduces leaf loss from leaves being thrown up in the air and over the back of the merger as the merger is going through the field. However, one should still be careful about ground speed of the merger as loose leaves in the windrow will tend to increase leaf loss during baling.

Generally speaking, operator settings and operation have a much larger impact of leaf retention than machinery design.

Try to minimize the distance that hay is moved across the ground when raking or merging. For example, rake swaths to the center rather than one side. The more that haylage is tumbled across the ground, the more leaves are lost.

We should consider that every time we move alfalfa in the field before baling, leaves are lost. This is both a yield loss and a forage quality loss. The goal should be swath to windrow and then to baler.

Baling loss for half-ton or larger rectangular bales of alfalfa on a straight-through baler generally ranges from 2% to 5%. This loss can be reduced by raking/merging when alfalfa has greater than 40% moisture and/or has dew on it.

For either rectangular or round balers, we recommend five-bar pickup designs. While more expensive than four-bar designs, five-bar pickup designs tend to leave less hay in the field and have reduced leaf loss.

Baling losses for round bales vary widely but generally range between 5% and 15% depending on plant moisture. Leaves tend to fall off between the belts as the bale is rotated in the baler. Some equipment manufacturers are considering going to three wider belts rather than six belts to reduce bale losses during harvesting. Producing baleage or haylage can help trim leaf loss given the forage crop is baled from 40% to 60% moisture.

Baling losses of alfalfa additionally occur as “fines” come out under bales exiting the baler, especially on small-square balers. Straight-through balers tend to have lower leaf losses.

Two additional considerations to reduce leaf loss, regardless of baler type:

- Maximize windrow size to the capacity of the baler or chopper. Besides saving harvest time and wheel traffic on the field, larger windrows result in less leaf loss at baler pickup.

- Match the pickup speed of the baler relative to ground speed. If pickup speed is faster than ground speed, windrows will be pulled apart going into the baler and leaves will be lost.

In summary, examine the alfalfa hay you are making and determine if it has significantly less than 50% leaves. Each percent leaf loss results in an approximate $7-per-ton loss from yield, forage quality and protein content at current market prices.

If you are unsure of the leaf percentage of your haylage, have a sample analyzed. This analysis can be particularly important if you have new equipment, new employees or a new contract harvester. It can ensure equipment is properly adjusted and operated to minimize your yield and quality loss during harvest.

Additionally, knowing the leaf percentage of alfalfa can be useful to nutritionists. Stemmy alfalfa will have slower fiber digestibility and higher undigested neutral detergent fiber (uNDF) than average. Quality alfalfa generally has a rate of passage of 5% to 6% per hour, while stem material has a rate of passage of 3% to 4% per hour; thus, high stem-percentage alfalfa (greater than 60%) will have lower rates of passage than leafy alfalfa. The uNDF of stems is also higher than that of leaves.

The following forage testing laboratories are known to offer leaf percentage analysis: Cumberland Valley Analytical Services, Dairy One Forage Lab, Dairyland Laboratories Inc., Rock River Laboratory Inc., and SureTech Laboratories.