James Nelson farms with his parents, Fred and Susan Nelson, and his wife, Anna, on a corn and soybean farm near Audubon, Iowa. James Nelson quickly recognizes the contributions of everyone in the family to the success of the operation. He says, “Our wives are very much involved in the operation. They do office work, but also run equipment, run the tractors, grain carts – anything that needs to be done.”

Nelson also does some custom spraying and covers around 4,500 total acres annually using an Ag-Chem 854 RoGator. The family wasn’t the problem; the farming wasn’t the problem; and the chemical application wasn’t the problem. The problem was the sprayer refill trailer.

For a refill trailer, Nelson was using a water tank and mix cone mounted on a wagon running gear, which wasn’t very efficient. Having the refill tank mounted to a running gear made for tough pulling down the road. It had no trailer brakes and didn’t trail well. Traveling distances was out of the question. To be safe, Nelson used co-op trailers to run back and forth from the co-op to the fields. Something needed to change.

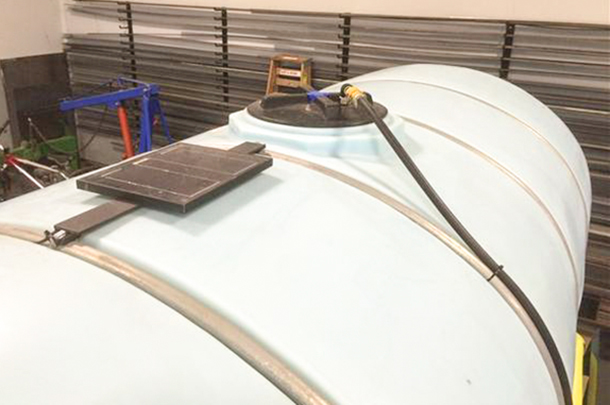

Nelson says, “I priced some factory built ones that had similar designs, but I thought I could improve and change things, and could do it cheaper myself.” Specifically, the factory-built trailers were very tall, and the first order of business was to lower the deck space and frame so it was easier to get on and off. Another improvement Nelson wanted was to increase the size of the working platform, which typically didn’t allow much room for operator movement or chemical storage. Beyond that, other handy modifications included adding a solar panel mounted to the sprayer tank to keep the bulk chemical pump battery charged, and extending the motor throttle handle and main valve to the top of the mix cone so the operator wasn’t constantly bending over to adjust motor speed or product flow. He also installed a float valve in the tank lid, so when the tank was filled with a garden hose overnight, it wouldn’t overflow.

During the winter months, Nelson began the project by choosing a tank that fully drained out the bottom without having to be on perfectly level ground. Every other design build would accommodate that number-one priority. Having the tank selected gave Nelson the idea for width and length, and after drawing the specs on paper, he literally chalk-lined the dimensions on the shop floor – including frame, fenders, tires, etc. This helped him get a grasp of what size the platform needed to be to accommodate the motor, mixing cone, mini bulk tank and working space.

Nelson used 2-by-6-by-1/4-inch rectangular tubing for the frame, with expanded metal for the platform. The saddle for the tank was constructed with 7-inch channel iron. Some of the supplies he had on hand, but many of the materials were purchased new. His best-guess estimate for the cost of the finished project is around $8,000, which doesn’t include labor. He spent two months working on the project, on and off, and didn’t track actual hours. Nelson had input on the design of the project from his dad, as well as fellow farmers from online ag forums.

Other supplies from his construction list include:

- Tank: Norwesco drainable leg tank, 1,610 gallons

- Mix cone: Norwesco 30 gallon full drain with Hypro jug rinse nozzle

- Pump: 2-inch cast Hypro pump with Honda engine

- Axles: Dexter 10,000-pound Torflex torsion ag axles with drum brakes

- Tires: 22.5 low pro

- Powder coating: Hired a local company to put the finishing touch on it

Nelson says, “I wanted to be able to use the pump on the tender to either pull from a stationary tank or obviously fill the sprayer without having to undo and switch camlock fittings at the pump. I used two three-way valves so I can just turn both of those valves and reverse flow from filling to unloading. I know the extra fittings reduce flow, but it still seems fast enough for me.”

The refill trailer weighs about 4,500 pounds empty, which is more than he anticipated, but Nelson says, “I would much rather overbuild it than rebuild it!” The sprayer refill trailer’s maiden voyage, so to speak, went off without a hitch when Nelson brought home a load of 32 percent UAN from the co-op to make sure everything worked.

Although the sprayer refill trailer wasn’t Nelson’s first rodeo (he’s undertaken many shop-build projects over the years), it wasn’t without challenges. Nelson says, “I made a pretty serious design error. I didn't study the specs of the torsion axles quite good enough and did not account for how far in the ‘arms’ of the axles stick inside of the brake drum. And since they had 0-degree start angle, there was interference of about a half inch on each side. So I ended up having to notch the frame and box it back in, adding about a day’s worth of work.” He says by special ordering the axles, he should have noticed the measurements beforehand and ordered exactly what he needed to fit. Nonetheless, with a fairly quick modification, he made it work.

Nelson says earlier this winter he built a 15-gallon cart on wheels to catch the oil for changing oil in tractors and combines; it is pressurized with air to drain it into a bigger tank, so that he doesn’t have to lift the used oil to drain it. He’s also previously built a clip-on tree puller for a loader tractor. Other earlier shop projects included a three-wheeled engine hoist, a stand to hold front-end weights off tractors so he doesn’t have to lift them off the ground and a modified side-dress application bar. With his dad he also built a scaffolding platform that clips into the loader tractor with a railing around it to work safer in the air.

But that’s all for this winter. It’s time for spraying and planting again. Nelson says, “Sometimes we catch a bad time for being grain farmers, you know, and supposedly we can just go on vacation for the winter, but that’s the time to work in the shop and build things and modify things and work on things. That’s how we save money and stay efficient.” FG

-

Lynn Jaynes

- Editor

- Progressive Forage Grower

- Email Lynn Jaynes

PHOTO 1: The final project has proven worth the effort, as James Nelson has now begun the 2016 spraying season with his sprayer refill trailer. He says, “We’ve run around 12,000 gallons of fertilizer through the trailer and it’s working great.”

PHOTO 2: In the beginning, James Nelson used actual chalk lines on the shop floor to help him better visualize the actual dimensions of his paper diagram.

PHOTO 3: The square, gray object on the tank is the solar panel installed to keep the bulk tank chemical pump battery charged. A float valve was installed under the tank lid (round object in the photo) to keep from overfilling the tank.

PHOTO 4: The finished sprayer refill trailer not only has a lowered and expanded working deck and storage platform, but it also has modified features that allow for safe transportation and ease of operation. Photos by James Nelson.