The key to an efficient hay season is a smooth startup. Making sure windrowers, mower conditioners, rakes, balers and other hay implements are ready to go when forage is at its peak maximizes uptime and helps ensure a successful harvest. Here are some useful maintenance tips to start the haying season off right.

1. Start with a walk-around on all equipment

For all equipment, make a thorough inspection of belts, chains, guards, bearings and other vital systems. It’s likely these were checked before equipment was stored for the winter, but a once-over is always recommended, especially for equipment stored outside. Wind, rain, snow and heavy condensation can cause rust as equipment sits idle. In colder regions, extreme temperatures can damage rubber components.

If wear items such as knives, discs and rock guards were not replaced at the end of last season, do so now to avoid unnecessary downtime during hay production. Additionally, producers will need to reverse any storage-related adjustments, such as pressurizing hydraulic systems and retensioning belts on machines where this is not automatic.

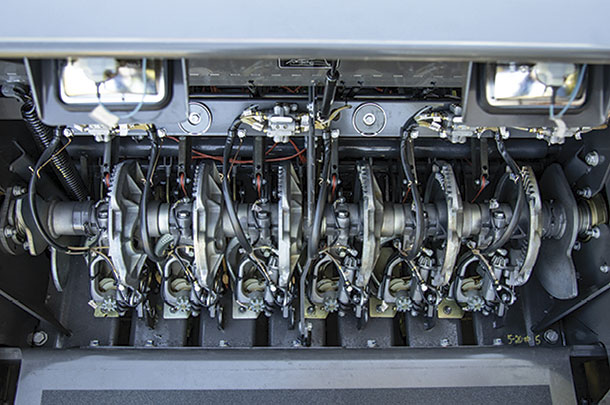

Before heading to the field, make sure oil is flowing for any system

that requires it, such as knotter heads in a large square baler. Photo courtesy of Hesston by Massey Ferguson.

Before heading to the field, make sure oil is flowing for any system

that requires it, such as knotter heads in a large square baler. Photo courtesy of Hesston by Massey Ferguson.

Before heading to the field, make sure all lube points are well greased and that oil is flowing for any system that requires it, such as knotter heads in a large square baler. Check gear boxes on tedding and raking equipment to ensure no leaks have developed over winter.

A careful inspection of tires and wheels is also recommended. Check that tires are inflated to the correct psi. Keep in mind, especially in early spring, fluctuating temperatures can cause slight variance in tire pressure. Keeping pressure within recommended range from the operator’s manual will minimize the risk of flats and blowouts.

In addition to a general once-over on all equipment, here are some implement-specific pre-season checklist items:

- Wheel rakes – In addition to tires, it’s important to make sure the bearings on ground-engaging wheel rakes are also lubricated and operating smoothly.

- Balers – For both round and square balers, the pre-compression chamber trip door, commonly known as a stuffer trip, is a vital component in overall bale quality. This system controls flake size. Ensure spring tension is correct and that the door actuates properly. A sticky stuffer trip results in overstuffing and oversized flake, while one that is constantly tripped can affect bale quality in forage that requires more than a 1-to-1 ratio.

2. Ensure equipment is set up for a specific field

It’s important to keep in mind that every field is unique. Last year’s equipment settings might not be ideal for the forage in front of you. This goes for new equipment as well, since factory settings might not be in line with conditions in your region. Before the first cut, it’s always a good idea to double-check machines’ settings are properly aligned to maximize forage harvest while minimizing dirt and debris pickup, which can increase forage ash content.

Making sure hay implements are ready to go when the forage is at its

peak maximizes uptime and helps ensure a successful harvest. Photo courtesy of Hesston by Massey Ferguson.

Making sure hay implements are ready to go when the forage is at its

peak maximizes uptime and helps ensure a successful harvest. Photo courtesy of Hesston by Massey Ferguson.

For first cuttings, raising the cutter bar offers several benefits. A cutter bar height of 4 inches or more allows for more air flow and faster drydown. A higher cutter bar also results in lower ash content for higher-quality forage. Additionally, a higher initial cutting can prolong stand life and make for better late-season results.

Producers using a roller conditioner will want to ensure the gap and tension are set correctly for the intended field. To ensure uniform crimping across all stems, conditioners should be set at a 1/16-inch to 3/16-inch gap depending on crop.

Rakes should be adjusted to ensure they pick up the maximum amount of dry matter without digging into the ground.

Any adjustments made on one machine should be followed up on subsequent equipment. For example, raising the cutter bar will require raising tedder and rake heights as well.

3. Think ahead for in-season needs

There’s no denying parts availability will play a larger role in 2022 season’s success than previously. Work with local dealers or other suppliers to make sure in-season maintenance and wear parts, such as tines or knives, will be available when the time comes. Looking back over parts orders from prior seasons can help producers determine what components to prioritize. Planning ahead now can avoid prolonged downtime during the hay season.

Start strong for 2022 success

Thorough pre-season maintenance can mean the difference between a productive, successful season or a hectic scramble to make up for unexpected downtime. But the benefits don’t stop there. Keeping up with routine maintenance can improve equipment longevity and provide a better total cost of ownership. Be sure to consult the operator’s manual for each piece of equipment and ensure all pre-season maintenance has been conducted before heading to the field.