Which equipment replacement plan is best suited for your operation? We’ll take a look at some of the options but, first, let’s break down machinery and equipment costs into five categories. These costs tend to change over the life of the machinery. Understanding how they change can help you make profitable investment decisions.

1. Depreciation is initially the largest expense, especially when purchasing new machinery or equipment. According to the American Society of Agricultural and Biological Engineers, brand-new equipment typically depreciates 30 to 50 percent of its investment value the first year.

After the first year or two of ownership, depreciation expense tends to decline gradually. Keep in mind, depreciation is a non-cash expense. Sometimes we can overlook it because we don’t actually write out a depreciation check.

2. Interest expense can be a cash or non-cash expense depending on how the purchase is made. If we take out a loan to make the purchase, we have an obvious cash expense. If we use our own money and pay cash for the equipment, we should consider the opportunity cost of our capital.

In other words, what interest revenue could we have made with our money in another investment? Regardless of how the purchase is made, interest expense, like depreciation, is greatest at first and declines each year we own the equipment.

3. Repair costs are usually minimal for new equipment, perhaps even zero while the equipment is under warranty but, as we all know, this honeymoon of repair cost-free bliss doesn’t last very long. The older the machinery gets, the more our annual repair costs will be.

4. Fuel and lube expenses don’t really change a lot over the life of the equipment, but they do increase some. Older engines tend to become less fuel-efficient and burn a little oil.

5. Downtime is the hidden cost we might forget to consider. Breakdowns cause downtime, which can be very expensive, especially during planting and harvest season. There aren’t many things more frustrating than being broke down – spending all day running to town for parts or up to your elbows in grease – knowing there is a big storm on its way.

Delayed planting and harvest can cost a lot in decreased yields, lower-quality crops and extra man-hours. Downtime also takes the fun out of farming and decreases stress, which we could probably place a value on if we got a little creative.

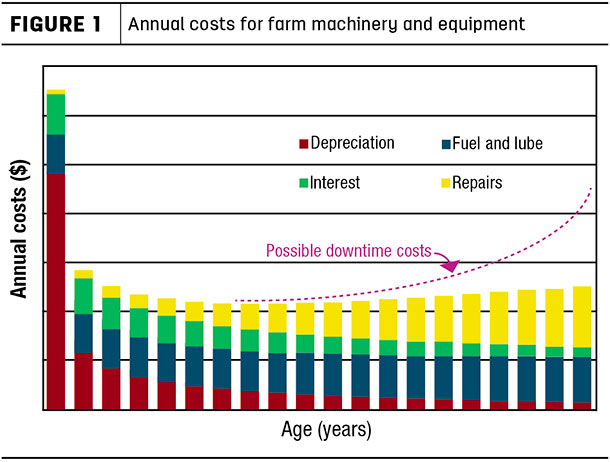

Figure 1 gives an illustration of annual costs for a tractor – it would be similar for most farm machinery and equipment.

So the question is: When is the best time to replace equipment? If you look at the typical textbook answer and only consider the first four costs (depreciation, interest, repairs and fuel/lube), the answer is: It doesn’t really matter. After the first few years, total costs don’t change much, even when the equipment is really old.

Decreases in depreciation and interest expenses are offset by increases in repairs and fuel/lube expenses.

Don’t forget downtime costs

Figure 1 doesn’t include downtime costs. You can use your past experience and imagination to draw an increasing bar representing your downtime costs. It probably starts out very small and insignificant when the equipment is new – but will increase steadily as the equipment ages.

At some point, the costs of owning and operating the old equipment (including downtime costs) will outweigh the replacement costs of a new piece of equipment. We need to consider an equipment upgrade before we reach that point. If we wait until equipment breaks down really badly or beyond repair, several things can happen. Here are some unpleasant scenarios we might face:

- Pressure to purchase replacement equipment at an inconvenient time

- Minimal or difficult financing options

- Loss of trade-in value on old equipment

- Loss of income due to downtime

Time to evaluate

Harvest season is now over for most producers. We can take a sigh of relief and reflect back on how the year went as far as planting and harvesting. How did we do managing machinery and equipment costs? Did our equipment operate efficiently, or did we lose too much money because of downtime?

Now is the perfect time to evaluate these questions and make plans for next year while the downtime pain is still fresh on our minds. It must be human nature to forget the pain. It’s like the nurse telling my wife she would soon forget the pain of childbirth and would eventually want another baby; the nurse was right, and it didn’t take that long to forget. Producers aren’t much different.

If we wait until after the new year or until next spring, we might forget the pain (and expense) of equipment downtime and relive the same pain another year.

General replacement strategies

Now let’s take a look at some common machinery and equipment strategies. Depending on your operation and management system, any one of the replacement plans can be optimal. For more information and detail, please refer to a very good Iowa State University extension publication titled, “Replacement Strategies for Farm Machinery.”

- Replace equipment frequently. Large producers who are most vulnerable to equipment downtime often employ this strategy. Equipment costs are going to be higher; however, the increased cost will be offset by lower repair expenses, less downtime and the ability to plan and harvest in a timely manner. Equipment leases and rollover ownership plans are becoming more common and more practical than conventional purchases.

- Replace some equipment each year. Another strategy is to replace something each year. Producers who have a fairly consistent annual cash flow or good cash reserves often like this plan. We can upgrade one or two pieces of equipment each year by making planned purchases and avoid large capital outlays that spring up unexpectedly.

- Replace equipment when cash is available. This is probably one of the most-used strategies, although we probably think of it more in terms of an income tax management plan.

With this plan, we delay equipment purchases until crop prices are good and we have a good cash-flow year. It may be a good plan for some operations, as long as the good years aren’t too few and far between. Otherwise, we can get stuck with some worn-out and less reliable equipment.

- Keep equipment forever. Another strategy is to hang on to a piece of equipment until it’s beyond repair. This may be the low-cost approach over time, but we run the risk of incurring some major downtime costs. This plan works best for operators who are good mechanics or who can keep a second piece of older equipment ready as a backup.

Machinery and equipment may always be one of the largest investments for farm businesses. When it comes time to upgrade or replace worn equipment, don’t overlook downtime costs. This winter take time to evaluate your equipment replacement strategies. Planning ahead will save you time and money – and make planting and harvesting a lot more enjoyable. ![]()

ILLUSTRATION: Illustration by Philip Warren.

-

Ben Eborn

- Agricultural Economist

- University of Idaho Extension

- Email Ben Eborn