Jock laughed and said that if that were the case, he must not be very bold.

Jock reviewed with me the benefits of aerial application for hay and forage growers. Jock lists speed of response and, of course, the lack of wheel tracks.

The airplane can apply chemical on wet ground and really shines when a new seeding of a crop needs chemical.

Any other method would tear up the tender seedlings. He’s done some aerial seeding in the past. The recommendation is to use a heavier seed rate than for other methods of seeding.

For aphids in hay, Jock says the systemic products are best if there is time for them to work. If the aphids show up just before harvest, there are other products that work faster.

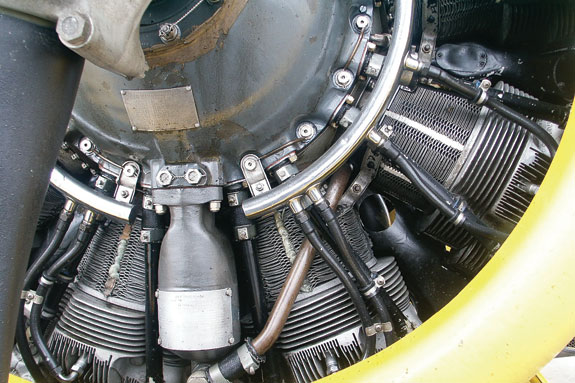

I asked Jock about his aircraft, particularly the engines. “Those radials are 1920s technology that we just keep rebuilding and flying.

We maintain them right here in the shop and only send them out for a full overhaul,” Jock explains. One is a Pratt and Whitney 1340 that puts out 600 horsepower.

The other is a Wright Cyclone that is good for 1200 horsepower. The Cyclone is the same basic engine that powered the B-17 bombers in World War II.

The smaller engine burns 38 gallons of gas per hour, while the Cyclone takes 55. The plane the Cyclone is on has a 500-gallon tank for chemicals versus a 400-gallon tank for the other plane.

World War I was a giant leap in the development of the airplane. The first use of aircraft as aerial applicators which Jock is aware of was in Germany in 1911.

Later, surplus WWI aircraft were used in other countries as well. “They were kind of crude airplanes but they got the job done,” Jock adds. The whole scene was crude at the start.

One of the first stateside uses of aerial application consisted of the pilot flying the plane and another person dumping bags of arsenic powder over the side, treating a pest in the catalpa trees in Florida.

Jock got his first flying experience flying float planes in Canada. He’s been a fixture of Royal City for a good many years now, with 42 years as an aerial applicator.

He credits Leland Snow with making the first purpose-built airplane for aerial application in the 1950s. For a number of years Grumman, Piper and Cessna built specialty aircraft as applicators.

Currently Thrush and Air Tractor are the two manufacturers of ag aircraft. Jock uses the Thrush aircraft but allowed as how both are excellent machines.

When asked about turboprop engines, Jock explains that they were interesting when jet fuel was cheaper than aviation gasoline, but now are both around $4 per gallon.

Jet fuel is very similar to #2 Diesel and the only aviation gasoline available now is 100 octane low-lead. He mentions that some of the applicators who had gone to the turboprops are moving back to the old radial engines.

Jock explains that flying the airplane is the easy part. Knowing when to turn on and turn off the valves is the hard part.

“Each load here, if mistakenly applied, could be a potential lawsuit,” is his comment. He explains that we now have GPS units to help and still use smokers to check wind direction.

He says that one procedure at the edge of a field is to turn off one of the booms (there is one spray boom on each side of the plane) and let the prop wash get the chemical to the edge of the field.

Jock’s training as an ag applicator was in the front seat of a Piper Cub airplane with the instructor in the back seat.

He says there is an ag flight school in Georgia and he employs one of its graduates. He mentions that Air Tractor makes a two-seat side-by-side plane specifically for use training ag flight students.

I asked Jock how dangerous it is to fly that close to the ground. “Altitude is your best friend. At least you have time to think.

When you are flying at application altitude and something happens, there is no time to think something through,” is Jock’s comment. He lists mistakes, mechanical issues and bird strikes with a big bird like a pheasant or duck as issues.

Also things like hitting a shovel handle someone had left standing up in the field. He’s been successful getting a wounded aircraft back home on a number of occasions.

“When you do something like blow a cylinder on an engine, it sounds really bad and blows a lot of oil, but you can usually get back home.

“The time once was that aerial applicators followed the crops. Any more, almost all of us have a solid home base. Things have changed over the years,” Jock adds.

Jock mentions that he has dropped water on wildland fires. “The insurance company limits the number of hours I can do that,” he explains.

He goes on that a single-seat fire bomber has been developed from an ag applicator plane. It carries 800 gallons of water or fire suppressant and is very popular as a first response to a fresh fire.

On the other end of the spectrum are converted Boeing 747s that cost $26,000 per hour to operate.

I asked Jock about misconceptions he’d like to straighten out. Jock answers with a question, “How do you address ignorance and stupidity?”

Activists who have no understanding of agriculture or where food comes from and judges who do not have enough fortitude to throw out frivolous lawsuits are two of Jock’s pet peeves.

He goes on that maybe 1 percent of the produce imported into this country is actually inspected. The countries of origin do not have nor enforce the environmental constraints agriculture has to live with in this country.

The Clean Water Act is another thing that gets Jock riled up. “With the buffer zones they want, if you have a 120-acre field with a ditch on three sides, that leaves maybe 20 acres you can apply chemical to. So far, Washington State requires a 300-foot buffer between chemical application and salmon-bearing streams.”

Jock stops long enough for a quick picture, then climbs into the waiting plane and after the standard pre-flight procedures, flies away. There is no other sound like that of a radial airplane engine. Beats the rumble of a Harley any day. FG

PHOTOS

PHOTO 1: Jock got his first flying experience flying float planes in Canada. He’s been a fixture of Royal City for a good many years now, with 42 years as an aerial applicator. He explains that flying the airplane is the easy part; ksnowing when to turn on and turn off the valves is the hard part.

PHOTO 2: The radials are 1920s technology that they just keep rebuilding and flying. They are maintained in the shop and only sent out for a full overhaul. Photos by Brad Nelson.