I’ve got it – but I’ll cover that later. I also started to think about a special piece of equipment that has played a vital role in accumulating our collection. I also figured since this publication has “Tales of a Hay Hauler,” a tale of a tractor hauler might fit nicely.

I feel it would be remiss of me not to spotlight the vehicle that has probably hauled almost every piece of equipment we have acquired in the 20 years we have been collecting.

This special vehicle is my 1997 Ford F-350 XLT, 4x4, crew cab, long bed with the legendary 7.3-liter PowerStroke diesel engine, manual tranny and 3.55 gear ratio. I can’t say enough good things about it, and anybody who has ever owned one probably feels the same way.

My dad special-ordered the truck for himself, and I can still remember when our dealer called the house to say it had been delivered. We went straight to the dealership to check it out, and I’ll never forget when I saw it for the first time.

The new truck was a tremendous upgrade from the F-250 and its 351 gas engine he had been driving since 1989. With the arrival of the new truck, the old F-250 was now mine, and I was thrilled to have it. It got a new paint job and a few repairs, and I was in business.

Dad drove the new truck for the first year and put about 30,000 miles on it, until he decided in his line of work it was going to get destroyed. He then turned it over to me and took the F-250 back for his work truck. I couldn’t believe it, but I knew it was now my responsibility to take care of the new truck and make it last as long as possible.

He still had to use it periodically for hauling his equipment and material, and I probably gave him as much heartburn about using it as he gave me by taking it for the day. The old F-250 eventually got parked and replaced by the 1997 F-350 regular cab PowerStroke diesel he bought and is still driving.

So here we are, 300,000 miles and 20 years later, and it’s still going just as strong as it did back then. I can’t imagine using anything else to transport tractors and equipment. I guess you could say I’m using “old iron” to haul “old iron,” but I wouldn’t have it any other way.

If someone had told me in high school I would still be driving this truck at 36 years old with two kids, I wouldn’t have believed it but, sure enough, I am. So thanks, Dad, for giving me the opportunity to own this great truck, and we’ll see just how long it will last.

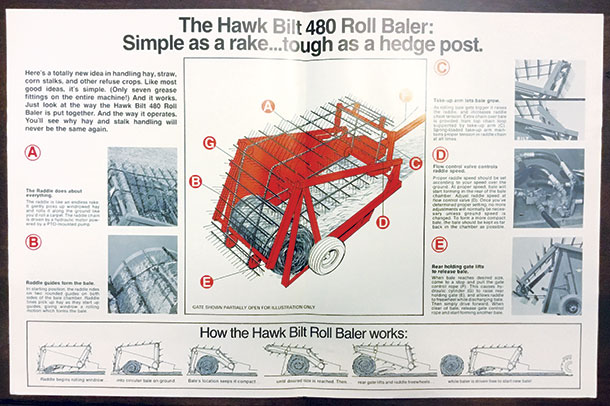

Now, on to a piece of hay baling history many people may not be familiar with and have maybe never even heard of or seen before – a Hawk-Bilt 480 Roll Baler. The best we can tell, it was bought new by Stuart Land and Cattle Company in Rosedale, Virginia, sometime in the 1970s.

Stuart’s is one of the oldest, continuously operating cattle farms in the U.S. still owned by the original family. We were so glad to be able to purchase this baler, as well as another one from a farm in the next county. There was only one other Hawk-Bilt in the area we know of, and we fear it may have found the scrap yard.

The Hawk-Bilt Company was in Vinton, Iowa, and they produced a variety of interesting implements. Their pitch for this machine was: “The one-man way to handle hay.” We were particularly drawn to this machine because of the unique way it forms the bale.

The baler is hydraulically operated by a PTO-driven pump with a self-contained hydraulic tank. The baler straddled windrowed hay, and the chain-driven raddle rolled the hay against the ground to form the bale. Once it reached the desired size, the tailgate could be raised and pulled away, leaving a nice, round, loose stack of hay – at least that’s the best way for me to describe it.

The ground clearance is adjusted by a ratchet binder on each wheel that lowered it completely to the ground and raised it enough for road transport. This baler does have a rare twine-tie option that used up to five strands of twine to wrap around the bale to make them easier to transport.

Each strand of twine is cut by two sickle sections mounted to make a sharp corner to cut the twine. Hawk-Bilt also made a three-point hitch as well as a front loader to more efficiently move the bales. We have yet to work on this baler, so we are still anxious to see how it all works.

By most all accounts, it wasn’t very practical for hay baling in our area due to the sometimes steep and rocky geography. It was common for them to turn over during baling or dumping, and the skid areas on the bottom of the baler are pretty banged up, especially on our other one.

Even with its drawbacks and somewhat awkward appearance, it is still a very unique piece of haying history that deserves to be preserved. I’ll definitely send an update when we are able to get it rolling again. ![]()

PHOTO 1: The Hawk-Bilt 480 Roll Baler is shown standing ready to be refurbished and back in service at my farm in Abingdon, Virginia.

PHOTO 2: My Ford truck as it is most commonly seen – hooked to a trailer with a load of tractors. It even makes a mostly blue Oliver 88 look good!

PHOTO 3: The original sales brochure and description of the Hawk Bilt 480 Roll Baler. Photos provided by Lance Phillips.