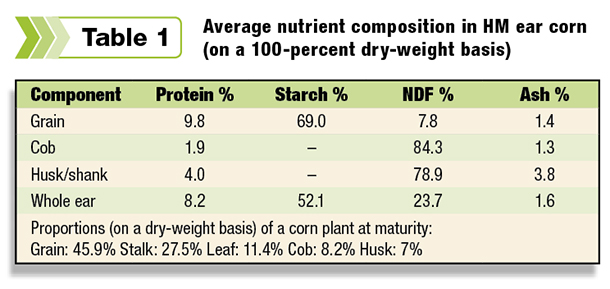

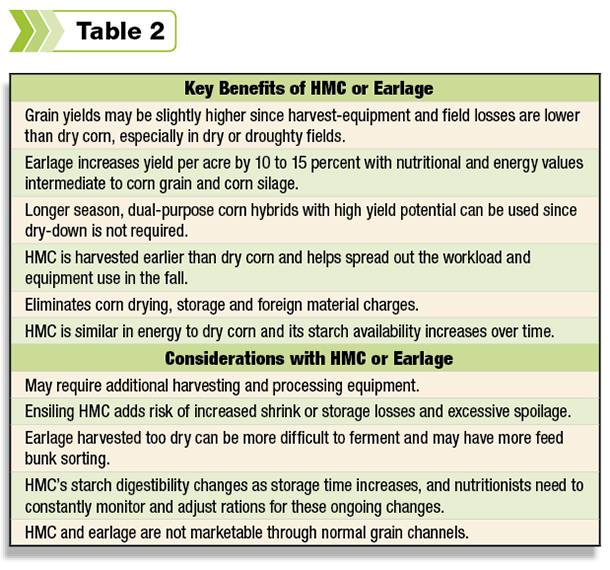

In recent years, dairy and beef producers have been harvesting more high-moisture (HM) ear corn (known as earlage or snaplage), thanks to improved harvesting equipment, such as snapper heads and kernel processors. This high-moisture grain product results from harvesting the whole ear, including the husks, cob, ear shank and grain. Harvesting earlage increases yield by 10 to 15 percent as compared to harvesting only grain, and earlage has an intermediate feed value compared to HM grain and corn silage. Quality of earlage depends on how much cob, husk and leaves are included in the final harvested product (see Table 1).

Several critical factors combine to make HMC or earlage harvest wildly successful if done right, or extremely costly if done wrong. These include harvest moisture, processing and fermentation.

Ideal harvest moisture: All in the timing

To maximize grain yield in HMC or earlage, harvest after black-layer formation, when the corn plant stops depositing starch in the kernel. But be aware of the grain moisture level; excessively wet grain may mean less efficient fermentation, and therefore, greater energy loss in storage.

On the other hand, harvesting corn grain or earlage that is too dry can result in yield reductions due to higher field losses, ear drop and exposure to weather conditions that encourage mold growth on the ear. Dry corn is also harder to process, pack and ferment successfully in a silo.

- High-moisture corn: A range of harvest opportunity exists, but in general you want to target 28 to 32 percent moisture content of the harvested grain. When corn reaches black-layer development, whole kernels range from 32 to 36 percent moisture content.

- Earlage: The ideal moisture content for the final earlage product is 36 to 42 percent. (Kernel moisture will be at about 34 to 36 percent at this stage.) Harvesting within the ideal moisture level range increases harvest efficiency and maximizes yield and earlage processing. In addition, cob digestibility is high in the ideal moisture range.

Kernel processing pays the bills

Processing HMC and earlage prior to ensiling aids in the packing and fermentation of the product in a silo. More importantly, early processing results in better starch digestibility of the corn when fed to livestock.

Corn’s key energy component is starch, but corn kernels are encased by a seed coat (pericarp) that restricts access to starch by rumen microbes. When broken or crushed, the pericarp and encased starch granules are reduced to particle size. As a result, microbes can more easily access the starch and capture the energy contained in the kernels.

- High-moisture corn: HMC is typically harvested with a combine and then processed at the silo with a roller mill, a hammer mill or a tub grinder. When rolled, kernels are cracked into multiple pieces and have fewer fines. Grinding usually results in a much finer material than rolling, but also has more fines due to the aggressive grinding action. Some farmers store HMC as whole kernels in oxygen-limiting silos and then grind the kernels at feed-out.

- Earlage: Earlage is harvested with a snapper head mounted on a forage chopper and run through the chopper’s kernel processor. When the kernel processor is properly adjusted, all kernels should be broken. When filling upright silos, use a distributor to help prevent separation of cob, husk and kernel material. Earlage contains substantially more trashy material and is harder to pack than processed HMC, so uniform processing is more critical with this material.

Inoculate and ferment to protect your investment

Grain is a high-value feed source for your dairy or livestock operation, and ensiling it increases your risk of loss due to spoilage. The fermentation potential of ensiled HMC or earlage is similar to that of other silage crops.

To assure an excellent fermentation and to keep the silage stable through feedout, use a research-proven inoculant specifically designed to ensile HMC or earlage. This inoculant should contain both Lactobacillus (L.) plantarum and L. buchneri bacteria species to achieve quick and efficient reduction of silage pH and help maintain aerobic stability on feedout. An appropriate inoculant will help keep your feed cooler and more consistent in the bunk, even during the warmest months of the year.

Finally, covering ensiled corn bunkers with plastic and sealing it with tires or other weights is critical. Any water or oxygen that penetrates exposed surfaces will quickly lead to heating and spoilage of this valuable grain. Similarly, when using silage bags, frequently monitor them for holes due to rodents or other animals and repair immediately.

Following these key management steps will help you harvest and ensile HM corn or earlage successfully. High-moisture corn and earlage continues to grow in popularity because it allows the production of a high-energy feed product that is easily harvested, stored and fed. For dairy and livestock producers, these products provide excellent feed. FG

Dan Wiersma

Livestock Information Manager

DuPont Pioneer