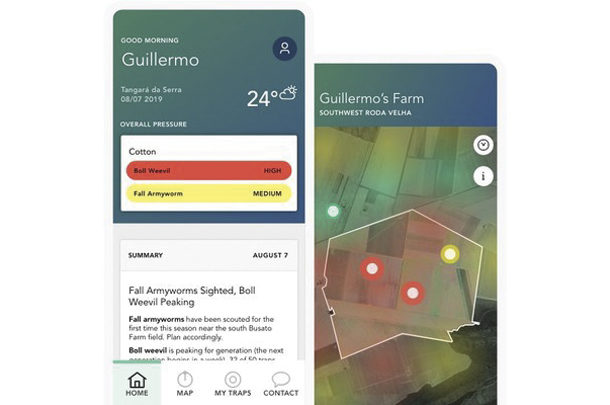

FMC Corporation announced the launch of Arc farm intelligence, an exclusive precision agriculture platform that enables growers and advisors to more accurately predict pest pressure before it becomes a problem. Arc farm intelligence is the first mobile platform to use predictive modeling based on real-time data to help ensure the right crop-protection products are applied precisely where and when they are needed to improve sustainability, optimize crop yield and enhance grower return on investment (ROI).

The innovative platform offers a full suite of features, including customized alerts through a mobile app to indicate when action is needed in a field, two-way communication with FMC agronomists, reliable data and high-quality graphics, including graphs and heat maps. Arc farm intelligence has been engineered with open application programming interfaces (APIs) and can easily be plugged into growers' existing digital ecosystems.

The platform will be launched commercially next week in Greece for cotton, and it is being piloted in other countries, including Brazil, Spain and the U.S., on a broad range of crops from brassicas to corn to lettuce. The Arc farm intelligence app will be available for growers in Greece for free from the Android and iOS app stores.

Arc farm intelligence is the latest addition to FMC's precision agriculture solutions. Other FMC precision agriculture solutions include 3Rive 3D application technology, a revolutionary at-plant crop protection delivery system that helps growers efficiently cover more ground in less time with fewer refills – saving water, fuel, labor and time; and PrecisionPac solutions, an innovative dispensing system that minimizes waste with custom herbicide blends specific to each grower's field size and weed spectrum.

Visit their website to learn more about Arc farm intelligence.

RhinoAg announced a new model in their successful single-spindle rotary cutter line.

The TW Series, RhinoAg’s flagship single-spindle product line, has been expanded from the current 5-foot and 6-foot options with the addition of the new TW37 model. This new model offers customers a cutting width of 7 feet and the same impressive 3-inch cut capacity to handle large jobs with ease. This new model also features a domed deck designed to reduce grass buildup and promote easy cleaning. The replaceable, full-length skid shoes and tapered side skirts reduce gouging to protect the deck and grounds.

The TW37 is equipped with the same cast “Infinity” blade carrier design that is seen on RhinoAg’s patented Flex-Wing rotary cutters. The Infinity carrier reduces vibration, provides a cleaner cut, increases vacuum, enhances discharge performance, and allows for easier service and maintenance with increased visibility.

TW37 cutters are available now. Visit their website for more information or to find a RhinoAg dealer.

John Deere introduces TC-series trenchers as latest additions to attachments lineup

Designed to fit the needs of construction, agricultural and landscaping professionals, John Deere debuted two new trencher models, the TC36 and TC48, to its family of attachments. The newly introduced TC36 and TC48 trenchers are ideal economic models for lighter-duty tasks and equipment rental. These attachment models are compatible on John Deere skid steers and compact track loader models, as well as most competitive models.

The TC-series trenchers are designed for lower duty-cycle customers in agricultural and light construction applications with several configurations to match most soil conditions or trench requirements. To ensure enhanced productivity, the TC36 and TC48 trenchers come equipped with a spring-loaded trencher boom that reduces system shock. The carefully designed frame provides easy ingress and egress during use. The crumber boom pulls loose soil into the trenchers, leaving a clean bottom, and an auger removes spoils from trenches, increasing productivity on the job.

Another key quality of the TC36 and TC48 trenchers is the ability to increase the operator’s uptime. The robust digging chain can be used for even the toughest conditions, and the integrated skid shoe helps stabilization while trenching. The angle indicator provides customers an optimal trenching angle for more accurate and precise digging. By incorporating a low-profile drive system and side shift, trenches will be nearly flush after every use. The multiple digging chain options combined with the low-profile drive system and side shift help incur lower daily operating costs.

To learn more about the TC-series trencher attachments contact your local John Deere dealer or, visit their website.

John Deere introduces entire new header lineup including drapers, corn heads and a belt pickup

John Deere has updated its entire header lineup for combines to include new HDR rigid cutterbar drapers, RDF HydraFlex Drapers, CR and CF corn heads and a BP15 belt pickup. Each is compatible with the John Deere X Series and most S Series and T Series combines to help achieve maximum harvesting capacity while minimizing grain loss under a wide range of crops and conditions.

John Deere HDR rigid cutterbar drapers are ideal for small grains, oilseed or soybean growers who want to maximize their combine’s acres per hour across various crops, changing conditions and uneven or rolling terrain while capturing more grain.

John Deere RDF HydraFlex drapers are built on the field-proven cutting technology of the existing John Deere 700FD while providing new features to reduce grain loss. These new drapers are compatible with new X Series, S Series and T Series combines dating back to model year 2012. All RDF HydraFlex drapers feature a new two-speed center feed section that lets operators slow down the feed drum and center feed belt by 20% compared with the 700FD.

These drapers, carryover the field-proven John Deere 4-inch double-cut, dual-drive shaft HydraFlex cutterbar. The knife system provides industry-exclusive cutting performance by making 1,980 cuts per minute to enable faster harvesting speeds. Two center feed belt options are available as standard equipment to optimize the RDF HydraFlex draper for multiple crops and conditions. The standard belt minimizes pod tossing in easy-shelling crops such as soybeans. An optional cleated center belt is available to feed higher-volume crops like canola into the feed drum.

John Deere dealers will start taking orders for the drapers, corn heads and belt pickup in late summer 2020. For more details visit your local dealer or their website. ![]()

PHOTO: Photos courtesy of FMC Corporation, RhinoAg and John Deere.