Feedout rate varies from one bale per 10 seconds to one bale per minute. All strings are cut and then automatically collected during feedout. It makes feeding hay a one-person safe operation. The Sinch Bale Feeder uses two hydraulic hoses and one grease nipple on the non-flaker model. U.S. models are mounted as standard-sized gooseneck trailers.

Rock River Laboratory releases new corn harvest tool

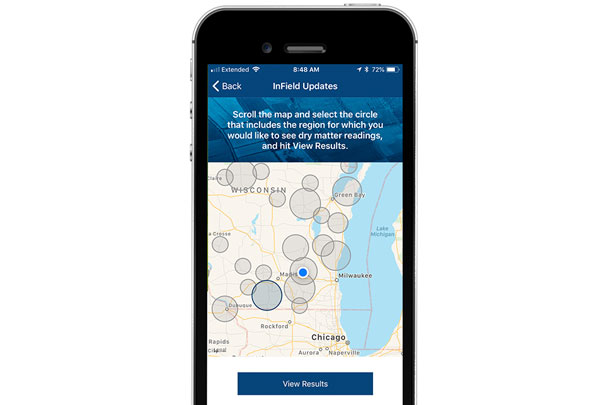

Rock River Laboratory Inc. has launched InField Updates, a new crowdsourced in-app tool that helps growers dial in the harvest timeline of corn intended for silage. Nutritionists, agronomists and their growers can now review timely fresh dry matter (DM), neutral detergent fiber (NDF) and starch statistics geographically to determine the optimal chopping schedule for their acres.

Development of the tool was sparked by the annual need for timely moisture assessment of corn intended for silage to predict chopping timing. The tool relies on the support of the industry to supply freshly chopped corn samples to Rock River Laboratory, which is requesting the help of all growers and consultants to make this tool beneficial for everyone. Samples submitted using the laboratory’s new, minimally priced ‘Fresh Chopped Corn’ package will receive a DM, NDF and starch analysis to help populate the information for InField Updates. Resulting data is mapped based on location electronically submitted while maintaining the privacy of both the individual submitting and the exact address location. The sample submitter will also receive their own specific sample analysis results direct to their email or on the company’s web portal.

To provide on-the-go access, the new tool resides within the company’s FeedScan app, the smartphone and tablet application for electronic sample submission. The new tool is free to everyone and does not require login credentials; however, downloading the free FeedScan app is required in order to access the InField Updates tool. The tool’s users can review mapped data by selecting an area on the map that narrows data points to a 10-mile radius to ensure the analysis levels provided are relevant to the geographical area selected.

Those who wish to contribute to the effort in addition to benefiting from the information can send freshly chipped corn intended for silage samples under the ‘Fresh Chopped Corn’ package, using the FeedScan app (with location services enabled) to submit at the closest location to the field where the sample(s) was collected. Physical submission of the fresh samples can be completed conveniently at one of many Rock River Laboratory drop boxes along their convenience routes. Users can find the closest convenience route drop boxes here.

FeedScan is available for download at the App Store (search FeedScan) and in Google Play.

Michelin rolls out CerexBIB 2

Farmers are using ever-larger machines to perform at high-load capacities while maintaining low pressures in the field. The Michelin CerexBIB 2 with IF and VF CFO+ designations innovatively pushes the load and pressure limits for combine harvesters and other large harvesting equipment. CerexBIB 2 is available now in nine front sizes and seven rear sizes.

The company’s CFO+ technology offers a second and lower 6-mph cyclic loading table over the standard CFO of one 10-mph cyclic loading table. Farmers may gain up to a 10 percent bonus in load-carrying capacity at the same pressure, or the option of carrying the same load at lower pressures to maximize floatation and traction, and minimize soil compaction. The company designed and tested these tire innovations in collaboration with leading equipment manufacturers. The CTIS-enabled CerexBIB 2 tire is engineered to ensure optimal harvest time despite soil conditions.

The new tire will be offered in the following front sizes: VF520/85R42, VF580/85R42, VF710/70R42, IF800/65R32, IF800/70R32, IF800/70R38, IFVF900/60R32, VF900/60R38 and VF900/60R42.

The new tire will be offered in the following rear sizes: VF500/85R34, VF520/80R26, VF520/85R30, VF620/70R26, VF620/70R30, VF710/65R30 and VF750/65R26.

Deere launches new rotary cutters

With an all-new deck and cutting chamber design, John Deere introduces a new family of rotary cutters. A variety of working widths and configurations are available to mow grass, pastures, CRP land, roadsides, parks, crop stalks or maintain large commercial lots.

The new rotary cutter lineup includes the E-, M- and R-Series that replace the existing MX, HX and CX Flex-Wing Rotary Cutter Series. E-Series Rotary Cutters include a new 12-foot (3.6-meter) E12 along with a 15-foot (4.5-meter) E15. Next up is the M-Series with M15 (15 feet/3.6 meters) and M20 (20 feet/6.1 meters) models. The top-end R-Series includes a 10-foot (3.05-meter) size, followed by the R15 (15 feet/3.6 meters) and R20 (20 feet/6.01 meters) models.

With an emphasis on improved cutting performance, the foundation of all three model designations is a new deck and cutting chamber design. Up front, a new suspended front mount improves machine stability by isolating the movement of the cutter deck relative to the tractor and vice versa.

A new torsional rear suspension system is an option for the M-Series and is included in the base package for the R-Series. The suspension further improves machine stability while delivering an improvement on cutting height.

E-Series cutters feature a 75-hp gearbox and Category 4 driveline. A 100-hp gearbox and Category 5 driveline are base equipment on the M-Series, with an option to upgrade to a higher performing 125-hp gearbox with Category 6 driveline. All R-Series cutters feature a new 125-hp gearbox and Category 6 main driveline for more capacity, improved durability and performance. ![]()

—Compiled by Progressive Forage staff

PHOTOS: Photos courtesy of Sinch Bale Feeders, Rock River Laboratory Inc., Michelin and John Deere.