Amity Technology introduces Crop Chaser multicrop dump carts

Amity Technology has introduced its Crop Chaser dump carts, including the CC1000 single-tank model and CC2000 double-tank model. They are designed to improve logistics of many harvest operations, including silage, grain and specialty crops. The dump carts feature a track undercarriage, which greatly reduces compaction and improves flotation when compared with trucks or wheeled dump carts.

The Crop Chaser series was engineered to add reliability and consistency to harvest operations. Trucks can be kept on field headlands, allowing crews to run more consistently with fewer weather delays, while helping to prevent the trucks from dragging large amounts of mud onto roadways. Furthermore, one cart load equals one truck load in most cases, providing a better flow of trucks running to the storage site, compared to using smaller dump carts.

The CC1000 single-tank model includes patented independent front and rear live wall chains for controlled unloading. It uses four hydraulic remotes for the tank lift cylinders and chains, giving operators maximum control over the dump rate. The CC2000 double-tank model has two separate tanks to split the load for natural control and stability when one tank is dumped at a time. Special load holding valves provide added safety by preventing the load from moving, in case of an unforeseen hydraulic issue.

Amity Technology markets its products worldwide in North America, Europe, Asia and Africa. More information on the company can be found here.

Photo courtesy of Harvest Tec

Photo courtesy of Harvest Tec

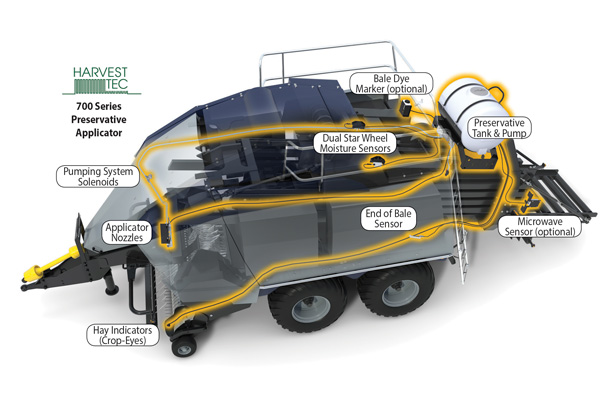

Harvest Tec introduces new 700 Series applicators

The most advanced preservative application for large square balers has been introduced as the innovative 700 Series applicator from Harvest Tec. The new technology makes the process of applying preservative easier and more efficient and has the capacity to match the speed and higher production of today’s large square balers. The 700 Series achieves greater reliability from engineered simplicity, fewer components and less maintenance.

The system monitors hay moisture with two star wheel sensors at the bale chamber entrance. The sensors use conductivity to read levels through the entire bale from 5% to 70% and provide the most accurate measurement in the industry.

Based on predetermined application rates set by the operator, the system’s control module activates a single bypass pump that supplies constant pressure to dual pulsating solenoids for instant response to changing moisture levels, controlling rates from 24 to 800 pounds per hour. Using the latest component technology results in precision delivery throughout the entire system and, most importantly, to the spray tips, ensuring precise application of the preservative to effectively protect the crop.

A choice of monitors

Baler operators can observe the continually changing moisture levels on their choice of monitoring device: the Harvest Tec virtual display, an Android or Apple tablet, or with most baler monitors. Information displayed includes current moisture levels, the reading of the last bale, amount of preservative being applied, the target rate, the average amount of preservative used and the total amount for the job being done. It also shows the current baling rate and the number of bales made. Job records contain additional information, including the average moisture for the field and the total tonnage baled.

The new 700 preservative applicator can make higher-quality feed for cattle and dairy and make bales with greater monetary value for producers who market their hay.

Harvest Tec’s new 700 applicator is available now through your hay tools dealer. For more information, contact your dealer, visit their website or call (800) 635-7468.

Photo courtesy Mecalac

Photo courtesy Mecalac

Mecalac offers new boom optimized for excavation and loading applications

Mecalac offers a new configuration of its innovative two-piece boom with offset for 6MCR skid excavators and 7MWR wheeled excavator models. The boom option allows customers to better tailor equipment for their specific needs.

The new option is a variation of the Mecalac boom optimized for excavation and truck loading applications. This alternative boom configuration positions the stick cylinder above the boom, rather than underneath, to provide a wider working angle, faster movement and higher penetration force, while maintaining the features that make the original Mecalac boom revolutionary on the excavator market. Dimension and work envelope remain similar to the standard boom, and attachments such as loader buckets and pallet forks are still compatible.

The new Mecalac boom is now the standard configuration for 6MCR and 7MWR excavators. The original boom design will remain standard for all other models in the MCR skid excavator and MWR wheeled excavator series, which provides unparalleled power and flexibility for diverse applications.

The boom is offset to the side of the cab, which allows the operator to angle the first part of the boom back to increase stability during lifting — resulting in the highest lifting force in its class — and reducing the machine’s overall footprint for work in confined areas. An additional offset in the second segment of the boom lets contractors dig outside the machine’s width as well as work parallel to the machine over longitudinal obstacles, such as fences.

Learn more about Mecalac’s innovative boom design, as well as its full line of equipment.

Photo courtesy of John Deere

Photo courtesy of John Deere

John Deere rolls out Performance Tiering Strategy starting with utility loaders

Developed in response to evolving customer needs and expectations, John Deere launches its Performance Tiering Strategy, delivering a range of products at different levels of capability and user experience. Available first on the wheel loader lineup, the Performance Tiering Strategy supports customers by providing machine solutions built for various applications and jobs to enhance profitability and efficiency. Moving away from the traditional series letter designations, the Performance Tiering Strategy provides three tiers of machines — G-tier, P-tier and X-tier.

- Adding a premium edge, X-tier models are built with the most innovative John Deere technology and features, delivering the highest levels of productivity, efficiency and customer experience.

- P-tier models can be counted on to produce at high levels, day in and day out. Advanced features deliver exceptional performance, efficiency, comfort and service life in demanding, high-production applications.

- G-tier models are practically equipped and economical, providing proven capabilities with the reliability and ruggedness expected from John Deere. These machines are ideal for customers in need of a reliable machine to complete common light- to medium-duty tasks.

The 444-724 P-tier machines reflect the performance capabilities and features that most customers expect from John Deere, such as those found on the current L-Series wheel loaders, including a redesigned cab, standard parallel lift Z-bar loader linkage, high-lift plus option, electrohydraulic controls and dual return-to-dig settings. A highly productive and efficient 5-metric-ton wheel loader, the 644 X-tier features E-Drive technology, comprises a diesel-electric drivetrain and exemplifies the type of innovative features that distinguish the X-tier.

The 644 G-tier is the first model to be available in the lineup of G-tier wheel loaders. Leveraging proven components and technologies, the 644 G-tier is equipped with an all-new cab designed to boost operator comfort and productivity. Customers can customize the machine through a variety of base-level packages, including axles, tires, ride control, seats, radio and rear chassis work-light selections. With the 644 G-tier machine, John Deere delivers a solution ideal for light to medium construction jobs, such as stockpiling, short load and carry, truck and hopper loading, and material handling.

Designed and manufactured by John Deere, all tiered machines are backed by the same level of excellent support that customers have grown to rely on, including John Deere Connected Support and a five-year subscription to JDLink. Customers can distinguish the different levels of tiering by not only their attributes and capabilities but also by the distinct branding and design cues on the machines.

The John Deere X and P machines are now available for purchase in the U.S. and Canada, and the 644 G machine is available in Canada and other global markets. Other product categories will follow our Performance Tiering Strategy over time. To learn more about the John Deere Performance Tiering Strategy, as well as the G-, P- and X-tier models, visit their website.