Ag-Xcellence has their baler performance monitor model BPM-101 on the market for any small square baler, new or old. The monitor includes a stroke/flake counter that can help you keep a consistent bale length and weight by counting the number of strokes or flakes in your bale. Counting flakes is important to keep balers as productive as possible. This unit can display in-chamber hay moisture via optional single- or dual-moisture sensor pads for one or both sides of the bale. This is a timesaver for knowing if conditions are changing without having to stop to check. The product also has a GPS ground speed sensor option that allows baler operators to know approximately how fast to go for conditions and to get back to the correct speed when turning around. By having all this data in one monitor, it reduces the number of monitors in the cab.

A flake counter allows a baler operator to make bales of more consistent length and weight. Most hay retailers and consumers at the very least appreciate bales of the same weight and length, but many demand it, sometimes with contracts. But let's think back to the beginning of putting up a cutting of hay, first you must choose when to cut in between storms, then get the hay to cure, usually with some combination of tedding and raking, now it’s time to bale and after getting a square baler to tie properly … you now need to get the bales out of the field. While removing and stacking bales by hand doesn’t mind bales of different length within reason (nevermind your back or labor cost), the mechanical bale-handling systems all work better with consistent length and consistent weight. Consistent bales can help make stacks more stable and less likely to fall apart due to the lack of differing lengths and weight distribution.

Knowing the bale flake count allows an operator to have a flake count target; if the target number is not correct, the operator can adjust his speed accordingly. Higher flake count means the ground speed is too slow, lower flake count means too fast. When the ground speed of the baler is adjusted to maintain the same flake count per bale despite the hay yield (tonnage/thickness) changes in the field, the bale weight and length of each bale are consistently close to each other. This is because hay flakes of different sizes compress at different rates; small flake compress tighter, and large flakes want to spring apart. By keeping the same sized flakes, the knotter can tie at the same length, and the amount of hay being compressed stays the same, leading to consistent bale weight.

As the monitor displays the flake count of the current bale being made, the number increases each time the plunger strokes. When the knotters tie the bale, the final flake count for that bale is shifted to the right, allowing you to see the previous bale’s count while the current count increases for the new bale being made. The previous bale counts are displayed for the last four complete bales. This feature is for seeing if the flake count is trending up or down to know if ground speed adjustments are needed. This prevents you from having to watch for each flake count to display and then keep mental notes of the last few bales. For more information or to view and explore this product please visit the website.

Photo courtesy of Zyter .

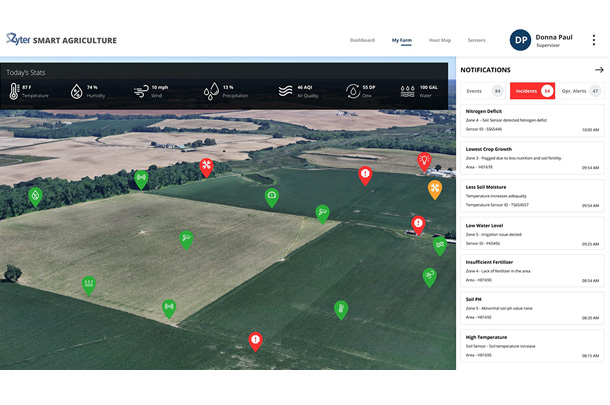

Photo courtesy of Zyter .Zyter introduces Smart Agriculture

Zyter Inc., a leading digital health and Internet of Things (IoT)-enablement platform, announced the introduction of Zyter Smart Agriculture, the latest IoT solution running on the Zyter SmartSpaces platform. With data captured by IoT sensors and analyzed with artificial intelligence (AI) technology, Zyter’s solution gives farmers and agronomists a comprehensive virtual view of the farm ecosystem with emphasis on automating and improving standard crop management practices to achieve more sustainable, precision agriculture.

Zyter Smart Agriculture gathers data on soil and atmospheric conditions from a network of IoT sensors buried in the ground and placed in various locations across the farm. In-ground sensors monitor measurement data that indicates soil health, including moisture, nutrients and solar radiation levels. Other IoT-enabled devices, such as weather stations, generate temperature, precipitation, wind speed and air quality measurements. All data is displayed in an intuitive graphical interface on the Zyter Smart Agriculture dashboard and mobile app. Zyter’s solution also displays notifications and alerts of soil readings that are out of optimal range. By replacing manual field inspections with automation, Zyter Smart Agriculture takes the guesswork out of soil monitoring and gives farmers a more accurate view of conditions.

Additional key features of Zyter Smart Agriculture include:

- AI-based actionable insights – The AI component of Zyter Smart Agriculture analyzes the streams of IoT sensor data over time to provide predictive analytics and suggestions of actions farmers can take to ensure an optimized yield. Farmers and agronomists alike can use these actionable insights to make more informed decisions on crop location, nutrients, irrigation, pest control and other crop management actions.

- Drone-based inspections with AI imagery – Drones outfitted with AI imagery technology automates the manual task of physically inspecting crop fields. The AI technology learns over time what healthy crops should look like and what conditions are ideal to support them. This data is fed into Zyter Smart Agriculture and analyzed to provide additional actionable insights for attaining maximum crop yields.

Zyter Smart Agriculture is currently live as part of the FarmGrid Precision Agriculture Solution at the Grand Farm showcase facility near Fargo, North Dakota. "The Zyter SmartSpaces platform is a great fit for our FarmGrid solution,” said George Woodward, president and CEO, Trilogy Networks Inc. “We standardized on the platform because of Zyter’s unique approach to simplifying data access from multiple sensors, controls and connected devices. This unique combination of FarmGrid and SmartSpaces unleashes the creative innovation from millions of developers globally working to feed the world’s expanding population.”

Zyter Smart Agriculture is one of the pre-configured IoT-based solutions that run on the Zyter SmartSpaces platform; the platform layer provides support for the Qualcomm IoT Services Suite. By collaborating with global IoT leader Qualcomm Technologies Inc., Zyter can support the 400-plus ecosystem members in the Qualcomm Smart Cities Accelerator Program. Through the Qualcomm IoT Services Suite, Zyter and Qualcomm Technologies can enable businesses and entities looking to adopt smart solutions through the unique model of adopting Internet of Things as a service (IoTaaS). The Zyter SmartSpaces platform breaks down silos of information by integrating and consolidating data from multiple IoT devices and applications into one seamless interface.

For more information on Zyter Smart Agriculture, visit the website. To request a copy of the Grand Farm case study, please email Michael E. Donner, Zyter chief marketing officer.

Photo courtesy of BullDog.

Photo courtesy of BullDog.

BullDog’s Premium 200 irrigation hose: The answer to reliable irrigation

Irrigation is a crucial input for those that require its use. As infrequent weather makes it unreliable for crops to access water, irrigation should be a reliable source, right? The answer to that question depends on the equipment and irrigation method being used. In the case of traveler irrigation systems, the most important piece of equipment is the hose. A cheap hose that isn't built for the task can be compromising to the health of crops and a grower's bottom line. So what is the best irrigation hose solution? The BullDog hose team will dive into which hose option is most ideal for irrigation applications.

When growers depend on an irrigation hose that's strong and reliable, they trust in the Premium 200 to get the job done. This is because of the hose's numerous design and performance benefits. Built in the U.S. as a lay-flat hose with a specially designed nitrile rubber extruded-through-the-weave material, Premium 200 boasts a number of features such as:

- Top-tier abrasion and cut resistance due to a premium rubber compound and heavy wall thickness, special exterior rib pattern

- High-tensile yarns promote low elongation and improved cut resistance.

- Long-term storage stability and working life

- Unmatched kink resistance

- Operating temperature range of minus 36ºF to over 158ºF

- Anti-burst technology with high-tensile yarns in hose construction

There are plenty of inferior foreign-made irrigation hoses on the market. And while they might seem like a cheap solution up front, they can cost a grower more in the long run. Trust in quality equipment truly matters in liquid transfer. Premium 200 delivers that and more.

To learn more about the Premium 200 hose and other hose solutions the BullDog Hose Company manufactures, visit the website.