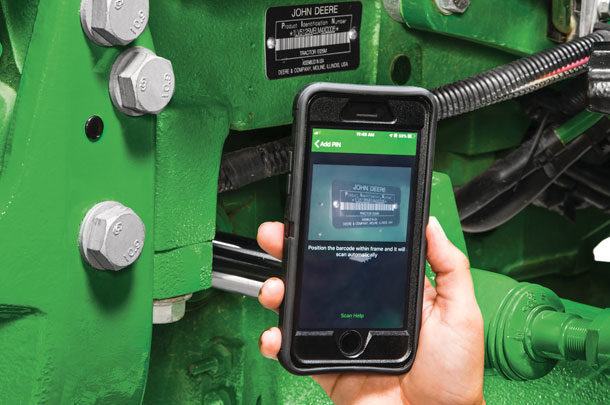

New John Deere Smart Connector establishes direct connection between tractor and smartphone

Tractor maintenance is simplified through the new John Deere Smart Connector and TractorPlus app for compact utility tractors. The Smart Connector establishes a connection between your tractor and your smartphone via Bluetooth technology for easy access to tractor information, like service intervals, diagnostic codes, fuel level, engine hours and maintenance information.

The TractorPlus app provides owners with convenient access to key parts of their operator’s manual, parts diagrams and parts ordering directly from the John Deere Store or their preferred dealer. Owners can also keep track of maintenance and service intervals for optimal machine performance and see diagnostic codes in an easy-to-read list.

In addition to providing valuable tractor information, the app also provides coverage mapping via your smartphone’s location tracking system for reduced overlap while mowing, plowing or spraying. In conjunction with the Smart Connector, the app can also function as an extended dashboard to your tractor by displaying real-time machine and job information.

Owners can also use the TractorPlus app to access a library of helpful how-to videos from the Frontier Tips Notebook for step-by-step information on topics like machine maintenance, property projects and more.

The John Deere Smart Connector is easy to install by simply plugging it into the Service Advisor port on your compact utility tractor. The entire process takes just a few minutes to complete and requires no tools for installation.

The new Smart Connectors are compatible with most 2-Series, 3-Series and 4-Series John Deere Cut models and can be purchased through your local John Deere dealer, or the John Deere Store.

To download the free TractorPlus app, visit the iTunes App Store or Google Play.

Photo courtesy of Kuhn.

Photo courtesy of Kuhn.Introducing Kuhn BV Series shredders

Kuhn North America Inc. is pleased to introduce the BV 10 and BV 100 Series shredders. These shredders are designed for a wide variety of orchard and vineyard crop operations. With a low profile, heavy-duty gearbox, redesigned hammer knives and counter knives, and a new roller, operators will have a shredding workhorse on their hands.

To help these shredders pass easily under low-hanging plants and trellises, the BV 10 and 100 Series were designed with an especially low profile in mind. The hood opening is among the best in the industry and provides operators with a large clearance range to increase throughput of branches and pruned material.

The heavy-duty gearboxes and new PowerQuad IV belt drive offer outstanding power transmission. A shaft transmits power from the main gearbox to the new PowerQuad IV rotor drive belts. These drive belts improve power transmission over previous models while using the same number of belts and are designed for reliable service with minimal maintenance.

Redesigned hammer knives feature a curved back to reduce damage to the rotor if an obstacle is struck. These heavy knives will easily power through clippings and brush up to 3 inches in diameter. There are also an industry-leading three rows of counter knives inside the hood of each BV Series to create fine clippings for quick decomposition.

The rear roller on the BV Series shredders feature removable ends, allowing a bearing to be replaced without replacing the entire rotor. It also features multiple height adjustments that leave the optimal grass height in a variety of situations.

Photo courtesy of Kuhn.

Photo courtesy of Kuhn.Introducing Kuhn HR 1030 and 1040 Series power harrows

Kuhn North America Inc. is pleased to introduce the HR 1030 and 1040 Series power harrows. These power harrows carry Kuhn’s solid reputation into a new generation with updated features and even better performance. Building on the success of their predecessors, these models have a class-leading driveline and offer operators the most rotor speeds in the industry.

Newly designed rotors and lubed-for-life gear trough reduce power consumption for high tractor fuel efficiency. The sides of the main gear trough are constructed from 5/16-inch- (8-millimeter) thick steel for outstanding structural rigidity. Treated forged-steel gears have a convex shape to transmit all of the drive forces at the center of the upper bearings.

All Kuhn HR 1030 and 1040 Series power harrows come standard with an adjustable leveling bar to create an even field finish. Hydraulic adjustability, available on the HR 1030 Series and standard on the HR 1040 Series, allows the operator to change the leveling bar and working depth from the comfort of the tractor seat.

Optional equipment is available to help customize each power harrow to an operation. These options can include quick hitch brackets and stone deflectors. One option allows users to select one of three roller types, MaxiPacker, MegaPacker or MaxiCrumbler, for the power harrow. Depending on soil type, these rollers play a critical role in creating a custom seedbed.

Photo courtesy of ARGO.

Photo courtesy of ARGO.AGCO to bring Fendt 300 Vario Series tractors to North America

AGCO Corporation, a worldwide manufacturer and distributor of agricultural equipment, will bring the fourth generation of Fendt 300 Vario tractors to North American producers for delivery in early 2022. The 300 Vario tractors are light yet powerful, offering the features and superior quality of larger Fendt tractors in a range perfect for hay and livestock production, field work and general farm use. Customers will be able to choose from models that all deliver the fuel efficiency, maneuverability and comfort expected from a Fendt.

Light, agile, productive and efficient

Two characteristics that will set Fendt 300 Vario tractors apart in the marketplace are their outstanding weight-to-power ratio and agility, traits particularly beneficial for loader work in tight quarters of livestock operations, inside barns and when feeding livestock. The 300 Vario will include four models, the 311 (100 HP), 312 (113 HP), 313 (123 HP) and the new 314 with 132 HP and up to 142 HP with the Fendt DynamicPerformance (DP) power boost. DP automatically adds 10 HP when it senses the need ‒ either pulling a load or when stationary, running a PTO-driven implement such as a feed grinder mixer. Especially notable, the premium Fendt 314 ProfiPlus won AgriTechnica’s Tractor of the Year Best Utility award in both 2019 and 2020.

With an unladen weight of just 11,045 pounds, the 314 Vario boasts just over 83 pounds per horsepower yet can be ballasted up to 18,739 pounds when the work at hand calls for more weight. These agile machines provide all of Fendt’s suspension innovations for ride comfort and stability, with a mere 13-foot turning radius. They are powered with a 4.4-liter AGCO Power engine that works in unison with the Fendt tractor management system (TMS), automatic maximum load control and Fendt stepless VarioDrive continuously variable transmission (CVT) for optimum power, fuel efficiency and machine life.

All tractor functions are easy to access at the operator’s fingertips. The tractors are controlled through the 12-inch primary display, the ergonomically designed multifunction joystick and control buttons, all integrated into the armrest itself. The new 10-inch “digital dashboard” is situated on the steering column. An optional 12-inch pull-down display recessed into the roof liner is available to provide up to 12 user-selected panels of information that can be shown across the armrest and pull-down displays.

Go to the Fendt wepage to learn more about the Fendt 300 Vario tractors or to locate the dealer nearest you.

Photo courtesy of Kuhn.

Photo courtesy of Kuhn.Introducing the Kuhn GA 4230 T and 4231 T single-rotor rotary rakes

Kuhn North America Inc. is pleased to introduce two new trailed single-rotor rotary rakes, GA 4230 T and 4231 T. These two rakes build on the popularity of the previous generation of Kuhn’s single-rotor rakes but now incorporate Kuhn’s exclusive Masterdrive GIII double-reduction gearbox technology.

Both rakes offer proven reliability with the Masterdrive GIII double-reduction gearbox allowing it to easily power through heavy crops, tough field conditions and intensive use. Key components have been improved, including the aluminum alloy housings, optimized cam tracks, larger follower bearings, tine arms with large-dimension bearings, sturdier pivoting tine support shaft, a reinforced main shaft and reinforced mounting of tine arms for the tine holders. The Masterdrive GIII’s ability to move heavy, wet crop, handle dry hay gently and neatly windrow corn stalks is unrivaled in the industry.

Other impressive features on these new rakes include double-curved tine arms, hydraulic headland lift and tandem axles. These rakes have been built to handle difficult, hilly terrain and these features reflect just that. Double-curved tine arms form fluffy, consistent windrows for superior raking quality at high speeds. High, hydraulic headland lift allows for smooth and easy turning, clearing previously made windrows. The tandem axles smoothly navigate bumps and holes in the field while keeping a constant distance between the ground and the tines.

For maximum operator efficiency, Kuhn Masterdrive gearbox equipped rakes have right-hand delivery for operator comfort and ease of use. This allows operators to easily monitor raking quality and make adjustments as needed.

Operators can have complete peace of mind when transporting these rakes. The GA 4231 T incorporates simple storage for the tine arms in the convenient rack at the front of the machine, and the guards fold vertically, while the arms are fixed on the GA 4230 T.