The two-auger system also opened the doors for feeding versatility. This cake feeder isn’t only tailored to feed conventional supplements such as cubes and grain, but also more nontraditional feeds like cottonseed hulls, and even candy. The auger door can be adjusted to dispense feed in a pile or down a line.

Another popular feature, the actuator kit, is a discharge chute lowering option that allows the driver to stay in the comfort of the cab when feeding.

Finding a fix for abused metal chutes was also a priority for the design team. The chutes, often kept open during feeding season, are subject to hungry, heavy herds and miles of fencing. The solution? A flexible rubber chute that eliminated wear and tear for long-lasting durability.

Introducing the new Batwing from Woods

More than 50 years ago, Woods introduced the original flex-wing rotary cutter, the Batwing. Today, Woods introduces a new generation of Batwing – the new BW15.50 flex-wing cutter. The new design is based on extensive research with customers and dealers. Focusing on giving the end users what they want and need, Woods created a machine that’s more reliable, more durable, easier to use, easier to maintain and built to perform better.

A variety of features make the new rotary cutter the most durable in the field. Steel tubes surround the perimeter to absorb shock, and chain shielding integrated within the frame prevents damage. The machine’s beefy, heavy-duty skid shoes prevent gouging and protect the deck from damage, increasing its toughness and durability. The machine is also equipped with features that ease maintenance, including grease fittings that are easy to reach and a smooth, sloped deck that’s free of components for easy cleanup and grease-able quick-change blade pins.

The company developed a new driveline lift assist system especially for the new 15-foot Batwing. With a locking feature and rolling mechanism, connecting the Batwing to a tractor’s PTO is quick, easy and simple. New gearbox seal technology with advanced engineering and material specifically developed for heavy-duty jobs in harsh environments results in less leaks and downtime.

In addition, only on this new machine will you find rounded wings that slice through brush, and a curved leading edge that easily maneuvers close to trees and poles. The calculated positioning of welded baffles optimize airflow for more even cutting and direct the cut material for superior distribution.

New Holland Agriculture adds new Discbine models

New Holland Agriculture is pleased to introduce two new disc mower-conditioners into its comprehensive product portfolio. The new Discbine 310 and 312 offer productive 10-feet 4-inch and 11-feet 6-inch cutting widths, a low-profile cutterbar and a choice of conditioning systems that will be at home in a wide variety of crops – from light grasses to sturdy bermuda.

The new 310 and 312 models are designed to mow cleanly and maneuver quickly to speed up hay- and forage-making operations. Unlike traditional, side-pull mower-conditioners, the versatile center-pivot machines with swivel hitch design have the ability to mow right, left or even in line with the accompanying tractor; this allows the operator to alternate mowing positions with every other pass.

The new low-profile disc cutterbar cleanly slices through tough crops, working at a shallow angle to ensure crop flows smoothly over the cutterbar and into the conditioner to provide even conditioning.

In addition to providing a clean cut on every pass, the new mower-conditioners provide peace of mind and time-saving, easy maintenance. Simple and convenient adjustments can be made while working in even the most difficult conditions, and a responsive mower suspension precisely follows field contours, resulting in reduced drying time and increased quality. Equipped with the QuickMax knife change system, the special knife release tool easily frees the blade from the disc so knife maintenance is fast and cut quality is ensured.

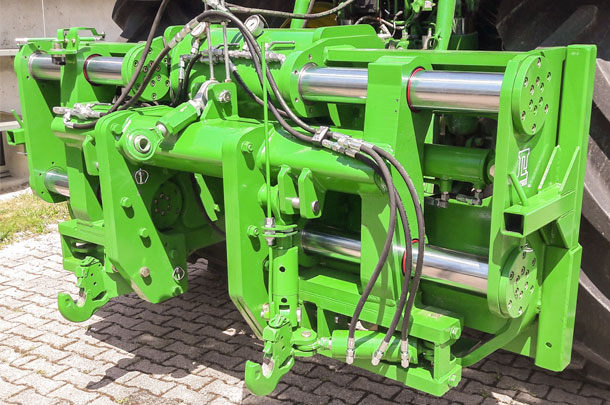

Universal guided hitch for rear implement

The Laforge DynaTrac is a key link between the implement guidance system and the rear implement by adjusting the lateral position of the implement based on the guidance line established by the tractor guidance system.

Laforge leveraged decades of tractor hitch experience and success in the U.S. with a DynaTrac for pulled implements to develop a three-point version with many benefits:

Versatile and universal guided hitch, compatible with:

- Three-point, pulled and semi-mounted implements – no need to purchase a specific implement or modify a standard one

- All tractors equipped with an active implement guidance module

- PTO driven implements

A key feature – decoupled motion through free lower link sway:

- Avoid side load on implement – no damage to the implement nor implement getting locked in the ground

- Better steering response of the tractor and better handling of slopes or curves than a rigid version

- Perfect implement trailing – tractor positioning corrections do not impact trailing

Brings active implement guidance benefits to all rear implements:

- Economical – no need to buy an interface for each implement (cultivator, planter, ridger, bedder, sprayer, etc.)

- Simple – only one software and a universal interface to handle

- Profitable – harvest the benefits of precision farming at each stage of the crop:

- Tillage (strip-till, bedder, etc.)

- Planting (place row precisely to guidance line and enjoy uniform row spacing pass to pass; place seed over fertilizer)

This product’s range fits any customer’s requirement and budget for precision farming: three-point (ultima version – tractor up to 400 hp, premium version – tractor up to 200 hp), and two-point or classic version dedicated to pulled or semi-mounted implements (tractor up to 400 hp).

FaStack bale stacker from Highline Manufacturing

Highline Manufacturing is excited to release the new FaStack line of large square bale stackers, including the model 1800 and model 1200 Flex. These easy-to-operate machines have industry exclusive features that will result in more bales picked in less time.

When every second counts, clear the field quickly. The Highline FaStack allows you to do more, faster. The model 1800 can carry up to 18 3X4 bales, 50 percent more per load than competitor models. One operator can effectively retrieve bales from the field and stack them efficiently, keeping the integrity of your bales intact, minimizing your costs and maximizing your productivity.

With this machine you can choose to stack your bales “on strings” (strings down) or “off strings” (strings on the side), and change your mind with every bale. The 1200 Flex gives you added flexibility as to where the bales can be stacked, whether it be in the field or in a shed.

Taking control of the machine is easily done from the cab. The remote control puts all of the unit’s controls in one hand, allowing you to easily drive the tractor and operate the machine at the same time. The company’s “bale-turn” technology allows you to stack your bales “on” or “off” strings, all with a simple flip of a switch from the control box in your cab.

The number of bales that can be stacked is determined by the size and orientation of the bale.

The model 1800 is able to load:

- 12 bales – 4X4, on or off strings

- 18 bales – 3X4, on strings

- 16 bales – 3X4, off strings

- 24 bales – 3X3, on or off strings

The model 1200 Flex is able to load:

- 12 bales – 3X4, off strings

- 8 bales – 3X4, on strings

- 8 bales – 4X4, on or off strings

—Compiled by Progressive Forage staff

PHOTOS: Photos courtesy of DewEze, New Holland Agriculture, Laforge Systems Inc. and Highline Manufacturing.