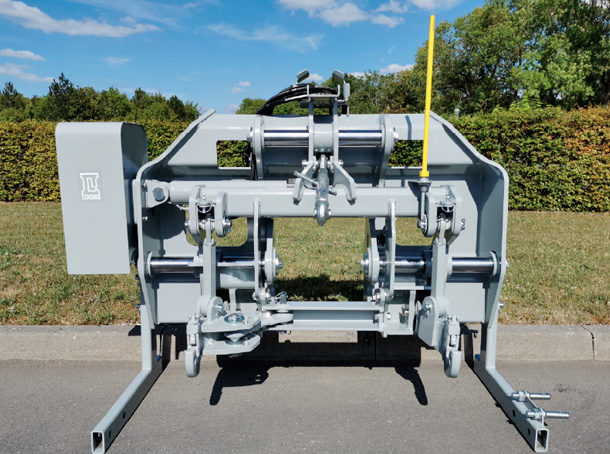

DynaTrac Compact: The solution for guiding all light implements effectively!

Laforge introduces a new model of DynaTrac to complement its range of implement guidance interface. This DynaTrac, named “Compact,” is perfectly suited to medium power tractors (70-150 HP) to accurately position light implements.

It is highly valuable for open field vegetable farmers and, more globally, all high-value crop producers looking for accuracy and repeatability at each step of crop production. It is also a great fit for row crop cultivators to upgrade them to work accurately, whatever the model, brand and age of the implement. It can guide all mechanical weeders of the market thanks to its universality. As an option, the company offers a Vision pack to steer the DynaTrac with camera inputs, as an alternative to GPS.

The DynaTrac Compact retains the optional lateral float feature of the arms (exclusive to the company), allowing to guide implements without lateral efforts. This improves working accuracy and reduces wear of working elements.

It also includes a vertical float feature for a perfect ground contour following by the implement. This way, the implement does not carry the weight of the interface. Consequently, it is easier to guide. The new product’s weight is on the tractor and improves its traction capacity, making its drive more accurate.

Technical specifications:

- 12 inches travel range

- Weight: 905 pounds

- Load capacity: Implement up to 3,300 pounds

- PTO compatible

- Lateral float feature with mechanical lock possibility

- Vertical float feature with mechanical lock possibility

Photo courtesy of AGCO Corp..

Photo courtesy of AGCO Corp..

AGCO introduces all-new Challenger MT800 Series track tractors

AGCO Corp., a manufacturer and distributor of agricultural machinery, introduces the all-new Challenger MT800 Series track tractors. Building on proven innovations from the company’s 30 years of experience in track tractors, these machines boast new engine and transmission combinations, an enhanced track and chassis system, more hydraulic and hitch options and a redesigned operator-friendly cab. In fact, these new tractors, equipped with the AccuDrive powertrain, are the most powerful two-track tractors available with a stepless transmission.

Tremendous power and fuel efficiency

Whether the task at hand is deep ripping, subsoiling, installing tile or high-speed planting, these tractors offer the power to get the job done quickly and efficiently. Producers can choose from among four models in the MT800 Series, all of which run reliable and proven engines by MAN. The MT851 (511 HP), MT856 (564 HP) and MT862 (618 HP) are powered by MAN 15.2-liter, six-cylinder diesel engines, whereas the MT867 (673 HP) is equipped with a MAN 16.2-liter six-cylinder diesel engine. Both power plants utilize a low engine speed approach that creates high torque even at lower speeds. AccuDrive allows for an engine speed range of 1,000 to 1,700 rpm, providing maximum torque from 1,100 to 1,450 rpm.

The Challenger Accu-VT continuously variable transmission (CVT) is engineered to optimize the benefits of track tractors. Accu-VT can achieve ground speed from 65 feet per hour to as much as 25 mph, all at reduced engine speed. The Tractor Management System (TMS) automatically controls engine speed and transmission ratio to ensure constant ground speed.

Maximum power transfer, minimal soil compaction

This efficient powertrain is harnessed to an innovative undercarriage backed by more than three decades of track system experience.

The series’ two-track design affords advantages over quad-track tractors. There are fewer components to maintain, which helps reduce operating costs. There’s also less weight, which allows horsepower to be directed to the task at hand, instead of moving the machine. Numerous ballasting options – including front and chassis weights – are available to improve machine balance, headland quality and drawbar pull capacity.

Whereas quad-track tractors have a fixed track width, the new tractor series allows for track widths from 88 inches to 128 inches, so operators can select a width for the specific task at hand or maintain controlled traffic lanes to reduce soil compaction across a field. Four track styles are available in as many as four belt widths from 18 to 36 inches, depending on the style. Suspended mid-wheels help to maintain constant contact on all surfaces, providing excellent ride comfort.

Increased operator comfort and productivity

Further improvement in operator comfort in both field and road conditions is achieved through the Challenger SmartRide suspension. The hard-bar front axle is connected to the chassis via the suspension system that uses coil springs with rubber dampeners. An optional load-leveling system, SmartRide+, integrates hydraulic cylinders within the springs, allowing the tractor’s pitch to be controlled. Not only does this help maintain the correct implement and linkage geometry, but a level tractor will also have an improved ride because suspension travel is optimized.

Challenger MT800 Series tractors are available in 2021 and come with a two-year or 2,000-hour limited warranty. For more information about these new tractors, visit the Challenger showroom.

Photo courtesy of New Leader Manufacturing.

Photo courtesy of New Leader Manufacturing.

Introducing the new NL600 by New Leader

New Leader Manufacturing announced the introduction of its latest New Leader spreader: the NL600 high throughput three-in-one pull-type spinner spreader. The NL600 is a multi-purpose, multi-season spreader that offers growers and custom applicators the ability to spread compost or litter, fertilizer and BioSul at higher rates and faster speeds, maximizing their time in the field and investment in their equipment.

Features and benefits of the NL600 include:

- High 608-cubic-foot capacity to manage large payloads resulting in longer times between refills

- 3 times the throughput as competitive units allow for higher rates at faster speeds

- 304-stainless steel bottom panel with poly floor liner, 304-stainless steel spinner fins and 304-stainless steel chain shields to resist corrosion and extend unit life

- Adjustable precision G4 spinner spreader technology with adjustable feed gate to allow for different densities and product rates

- Tractor or PTO hydraulics

- Optional ISOBUS scale system with six weigh beams for static in-field calibration

The NL600 is available now through authorized dealers. For more information, visit the New Leader website.

.jpg) Photo courtesy of Industrial Irrigation Systems.

Photo courtesy of Industrial Irrigation Systems.

New video highlights customizable, reliable irrigation engines for farmers

The Propane Education and Research Council has added a new video about an innovative new line of Reliable Horsepower engines from Industrial Irrigation Systems (IIS) – featuring new efficiencies, reduced maintenance time and a complete electronic fuel control system.

Reliable Horsepower engines are built for longevity and durability, which begins at the first stages of the engineering process, followed by vigorous product testing and application review. While the base configuration is similar, the company makes adjustments to customize each engine for customer needs.

With over 65 years in the industrial engine business, IIS has offered a variety of engine brands and fuel types over the years but relies on propane to meet customer demands for EPA emissions regulations and successful engine operation in remote locations.

Reliable Horsepower engines feature advanced design valve-trains, hydraulic roller valve lifters, higher compression ratios for improved horsepower and performance, and integrated piston oilers for cooler engine operation and longevity. For more information, visit the product website.