This is a very hot topic in the dairy industry, as there are many different opinions, and every producer is likely to have a fairly unique goal and set of circumstances that will form the answer to this question.

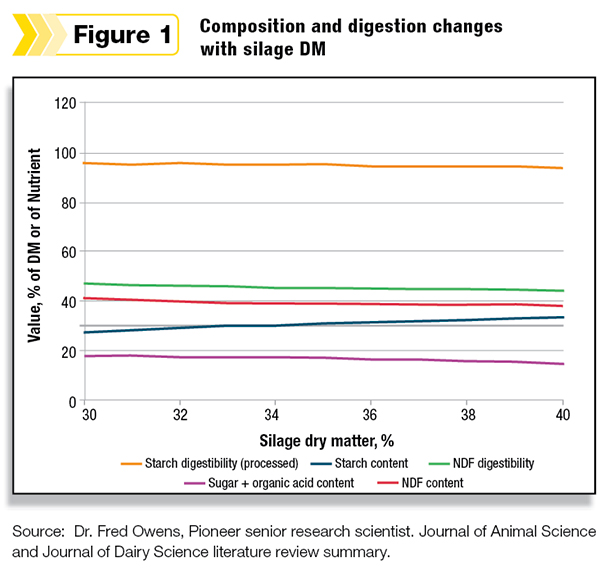

As an example of all the dynamics at play, take a look at the following chart. This chart shows the typical range in silage dry matter (DM) as we progress through the harvest window. Starting on the left side of the chart at 30 percent DM (70 percent moisture), starch content is the lowest and fiber digestibility is the highest. Starch digestibility is also highest at this point.

As you allow the corn plant to dry through the harvest window, you will see a dramatic increase in starch content. You will also see an increase in yield but a slight decrease in fiber digestibility during this time frame. Finding the sweet spot that fits your needs is the balancing act you will need to master in order to harvest when both the quality and quantity of feed match your needs.

I get asked a lot in the fall about when to start the harvest of corn silage. This depends on many factors. Every year is different, so you must be prepared to make adjustments to your plan. The goal is to harvest your corn silage when it’s at the most ideal DM for your operation.

It is best to walk the fields to determine what actions might be needed. Drought-stricken corn silage with a small ear will dry very slowly, so you can delay harvest in those fields. Well-eared corn silage will dry quicker, since the ear will be using a lot of the moisture in the corn plant, and late-season rains will provide much needed moisture for the corn plant, keeping it healthier.

Make sure you factor in enough time for harvest and possible rain delays. With scouting information, and by asking lots of questions, you can then make some adjustments to the overall harvest management plan based on what’s happening in each field.

Other factors to consider as you work through your harvest plans are length of chop and packing density. As the harvest window progresses and the silage gets drier, it will become more difficult to pack. Adjustments will have to be made to your cut length or the amount of pack or both. It may require adding more tractors as you progress to drier corn silage.

I recommend taking moisture samples regularly throughout harvest and making adjustments as needed.

The type of storage structure for your corn silage will also have an effect on your harvest DM, as there are different targets for each of them. Most silage bunkers and drive-over piles target the 32 to 38 percent DM, while a silage bag may target the 35 to 40 percent DM.

Upright silos also have specific targets, varying by structure type. Make sure you harvest your corn silage at the correct moisture range for the storage structure you have on hand and adjust accordingly to suit your feeding needs.

Corn silage harvest is a busy time. Make sure you have your plan in place based on your operational goals. Have all your consultants meet ahead of time to help with the management and to get comfortable with the plan, and be safe during harvest. FG

Matt Laubach

Dairy Specialist

DuPont Pioneer