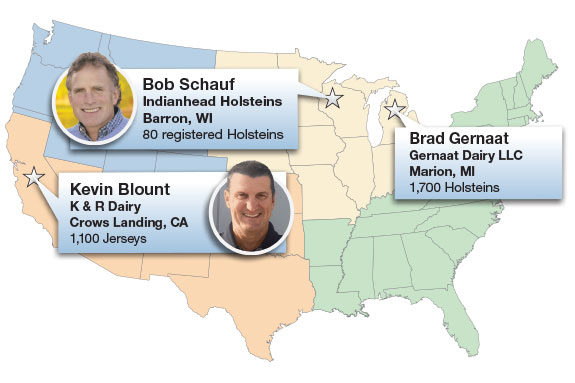

Three producers discuss tested management strategies for growing quality silage.

Q. What are your farm’s goals for silage yield and quality?

Blount: I used to focus a great deal on yields, but now we strive for quality. Quality silage is critical to meeting our overall farm goal of producing the highest-quality milk as efficiently as possible. If I can achieve high-quality silage at 30 to 32 tons per acre, I’m really happy.

Gernaat: We try to produce the best-quality silage we can using our land base and resources. The more silage we can grow ourselves, the better our cows do. On our non-irrigated ground, we consistently average 18 to 19 tons per acre.

Schauf: Quality is our real goal because healthy silage helps us produce a high amount of milk at the lowest cost. We had the best-quality silage we’ve ever had in 2012. The highest yields we’ve ever had were 27 to 28 tons per acre.

Q. What are your biggest obstacles to producing quality corn silage?

Blount: I think our biggest challenge is willingness to change. The new hybrids seem to be more sensitive to moisture levels. We’ve really had to become water-conscious to reduce plant stress.

Gernaat: Storage has been our biggest challenge. We used to store silage in bunkers, but we experienced too much shrinkage. We now use piles. We limit width, pack all the way across and cover immediately with plastic. We work to put the best possible crop in the pile to get the best possible feed out.

Schauf: We can do everything right when it comes to planting, managing and harvesting, but it’s still up to Mother Nature what the weather will do. We were hurting toward the end of the past season by drought but were fortunate to have late-season rains to save us. We just try to do everything we can to give the crop the tools to yield well.

Q. What are your secrets to successful silage growing?

Blount: Storage is our key to success. We used to store silage in a pit and cover it. Even though we were picky about packing, we still had too much spoilage at 15 percent to 18 percent.

We used a bag to store our BMR corn silage and were down to 2 percent to 3 percent spoilage. This year, we bagged all of our silage. Considering how much we’re investing and how important the end product is, we just can’t afford spoilage.

Gernaat: We start by planting at the optimum time, then we watch agronomic factors closely. From proper seed placement to spray timing and moisture at harvest, our entire silage program has to click.

Schauf: We continue to look at new ways to enhance the silage-growing process. We learned about kernel processing a few years ago and incorporated it into our harvesting plan. We’re now reviewing chop length. If new technologies make sense, we work them into our program.

Q. How does soil testing factor in your silage program?

Blount: We look at soil testing as one part of the overall cropping program. We rely on our fertilizer company to run the soil test. We find out what we’re lacking and remedy it.

Gernaat: We run soil tests every three years for pH and all nutrients. We strive to always be aware of what’s going on in any given field. That keeps us on top of our management decisions.

Schauf: We manage our ration from the soil up. Soil testing is a critical part of our silage-growing process. Over the years, we’ve tried high-calcium limes and gypsum to make sure we’re giving the seed everything it needs.

Q. How does variety selection impact silage yield and quality?

Blount: The hybrid has a huge impact on the final product. This is our third year planting BMR, and we’ll never go back. We started using BMR for the improved digestibility by the cow, but we’ve kept using it because it’s been so easy for us to manage it for great quality.

Gernaat: We want hybrids that are highly digestible so the cows can use it, and we need hybrids that work on our land. We’ve had super high-yielding hybrids that the cows didn’t use well, and that just doesn’t work.

Schauf: Variety selection is critical to meeting our silage goals. Hybrids keep getting better and better, and the BMR hybrids have definitely improved. At first, we gave up yield for digestibility. Now, BMR is competitive with conventional silage yields.

Q. How does feeding quality corn silage affect the overall success of your dairy?

Blount: Corn silage quality is one of the biggest factors affecting production. When the quality isn’t there, we lose milk production and end up spending more money on grain.

Gernaat: Corn silage quality directly affects our bottom line. Raising quality silage is key to keeping our inputs low and keeping our cows producing milk.

Schauf: Quality is the bottom line. The higher the quality of silage, the more efficiently the cows can produce milk, and the better we can do with our cows. FG

—Contributed by Mycogen Seeds