To reach these ends, avoid harvesting corn silage outside of the ranges of optimal moisture and maturity.

Silage maturity impacts nutritional value

Corn silage maturity at harvest has a dramatic impact on the nutritional value of individual hybrids. Corn silage is a grass plant containing digestible fiber with high-moisture corn attached.

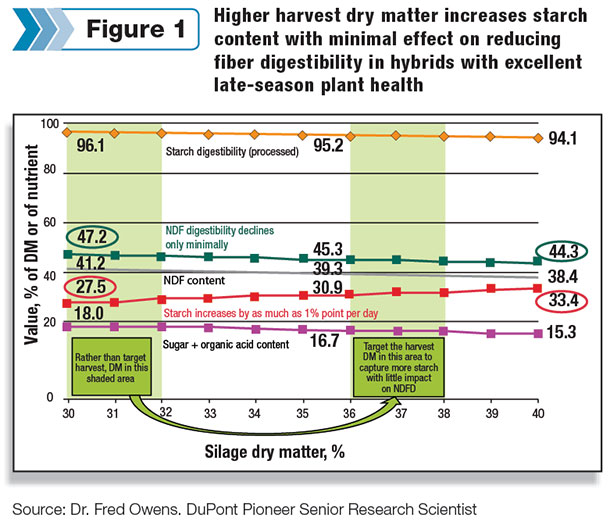

The increasing starch content as the plant matures is responsible for most of the improvement in feed quality as harvest approaches.

These gains come without reducing fiber digestibility in hybrids with excellent late-season plant health, stalk strength and standability.

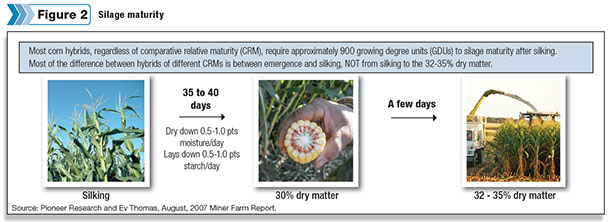

To get a handle on this, it’s important to know corn’s late-season growth stages. The corn plant will approach silage harvest maturity at about 35 to 45 days, or 900 growing degree units (GDUs) after silking.

The primary variance between hybrids of different relative maturities is the length of time between emergence and silking, not from silking to harvest.

The “35-45 day post-silking” rule of thumb aims for a 30 percent whole-plant dry matter (DM) value. Current recommendations are to target a minimum of three-quarter kernel milk line and a whole-plant DM closer to 35 to 38 percent.

This shift reflects the advanced agronomic traits available with newer technologies and genetics that confer improved late-season plant health.

The importance of correct moisture – when the crop is too wet or immature

Harvesting corn silage before plants reach optimal moisture levels reduces yield per acre and starch deposition, resulting in a hidden economic loss.

Harvesting corn silage at moisture levels above 70 percent will not only reduce yield but may also result in seepage and undesirable clostridia fermentation.

Clostridia bacteria are inefficient; they convert forage sugars and organic acids into butyric acid, carbon dioxide and ammonia.

As a result, the silage may have high levels of foul-smelling butyric acid, with a higher pH and high dry matter losses – in addition to poor feed quality, palatability and intake potential.

The importance of correct moisture – when the crop is too dry

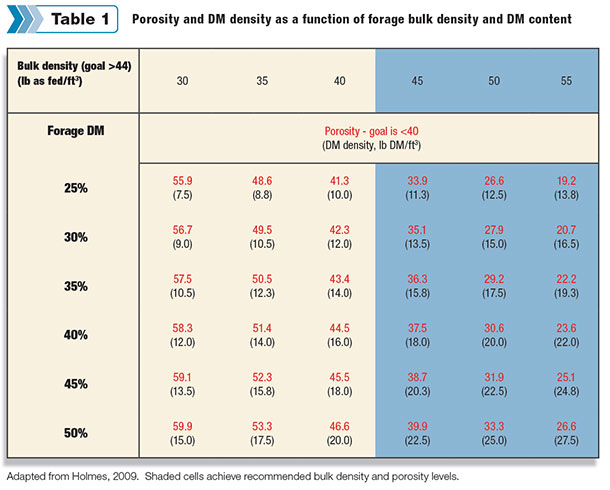

Packing bunkers and piles is a critical part of ensuring quality silage. Poorly packed, low-DM corn silage will have an extended plant cell respiration, resulting in an increased loss of digestible nutrients.

Trapped air can allow the growth of aerobic micro-organisms (harmful yeasts and molds) detrimental for the ensiling process.

When exposed to air again, yeasts already in the silage can grow and consume lactate. This reduces the feeding value of the silage by generating heat, which can make readily digestible nutrients and energy volatile.

Density is measured at the bunker, but it is really porosity (trapped air plus air movement) that advanced management approaches are trying to reduce.

The goal is to target porosity values under 40 percent, ultimately reducing trapped oxygen and oxygen penetration into the exposed face.

Proactive management of optimal silage maturity – on-farm field testing

Growers need to ensure the corn crop is at the optimal silage maturity and moisture level before the silage harvest crew hits the field and the silage is harvested. In addition to monitoring the silking date, the kernel milk line can also be monitored.

This is done by breaking a cob in half and looking at the kernels. After denting, you can see a whitish line on the kernels. This line is where the solid and liquid parts of the kernel are separated while maturing and drying.

The line will progress from the outer edge of the kernel toward the cob. When the milk line reaches the cob, a black layer will be visible.

The traditional recommendation has been to harvest when the milk line is between one-half and two-thirds. However, there is considerable variation in the progression of the kernel milk line and the moisture percentage of the whole plant.

University of Wisconsin data over many years show a range in whole-plant moisture at one-half milk line of 52 to 72 percent with an average of 63 percent.

Research suggests silage that is not processed achieves maximum net energy yield at 34 percent DM (66 percent moisture).

Silage processed with a kernel processor achieves a maximum net energy yield of 37 percent DM (63 percent moisture). Keep your harvest management plans in mind when determining optimal harvest dates.

Sampling fields

Monitoring silage moistures throughout harvest can help achieve the right balance between yield, starch and DM. Harvesting too late risks poor packing and incomplete fermentation. Sampling fields is the best way to monitor plant maturity and harvest timing.

To do so, you should gather 10 plants from multiple field locations and then chop the plants in a chipper or shredder.

To assess the moisture content, cook a 100-gram sample in a Koster moisture tester until no further weight loss occurs. The matter percentage will be 100 grams minus the grams of moisture obtained.

For instance, if 65 grams of moisture are removed, the dry DM content is 35 percent.

For a detailed assessment of on-farm moisture measurement techniques based on studies conducted by the UW Soil & Forage Analysis Lab at Marshfield, Wisconsin, refer to “On-Farm Moisture Testing of Corn Silage” by John Peters.

In summary, the nutritional value of corn silage can be greatly affected by harvest timing. When growers harvest too early, they compromise starch and feed quality.

Harvesting too late leads to lower feed quality and poorly packed bunkers. Therefore, growers should pay significant attention to plant maturity and moisture levels prior to and during harvest. FG

References omitted due to space but are available upon request. Click here to email an editor.