Advantages of wet corn include earlier harvest (by three to five weeks), higher energy value compared to dry corn (3 percent higher per unit of dry matter in dairy cows), lower ear loss or drop in the field, and the ability to establish a cover crop earlier in the fall.

Disadvantages of high-moisture corn include that it must be fed to livestock or sold to an ethanol plant, transportation costs are higher due to higher moisture level if sold, a risk of mold or yeast formation during storage or at feedout, and minimum daily feedout rates based on surface of the storage unit (bunker silos, piles, plastic bags or upright silos/oxygen-limiting structures).

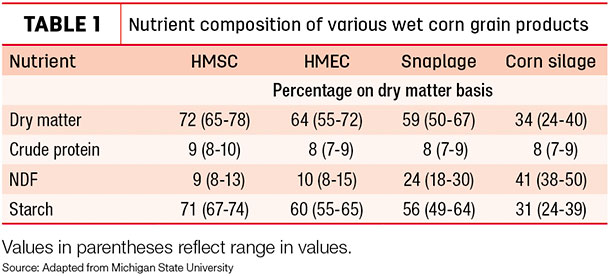

Three types of high-moisture corn can be considered on livestock farms (Table 1).

- High-moisture shelled corn (HMSC) is harvested by combines that harvest only the corn kernel or grain. This product is typically the driest type of wet corn. HMSC requires processing before going into storages (use of a roller mill or grinding unit at the ensiling site).

- High-moisture ear corn (HMEC) can be harvested with a combine that can retain 50 to 100 percent of cob material or with a corn picker. This product includes both the wet kernel and cob. The cob contributes 20 percent more yield per acre and contains more moisture (4 to 6 percent higher in moisture compared to grain moisture).

- Snaplage is harvested with commercial forage harvesters with a snapper head. The wet corn consists of grain, cob, husk and plant parts above the ear (could be leaf and/or stalk material). Because of this variability, snaplage can vary in quality. Snaplage yields can be 20 to 25 percent higher compared to HMSC. HMEC is not the same as snaplage – be sure you make this distinction when using snaplage.

Snaplage research

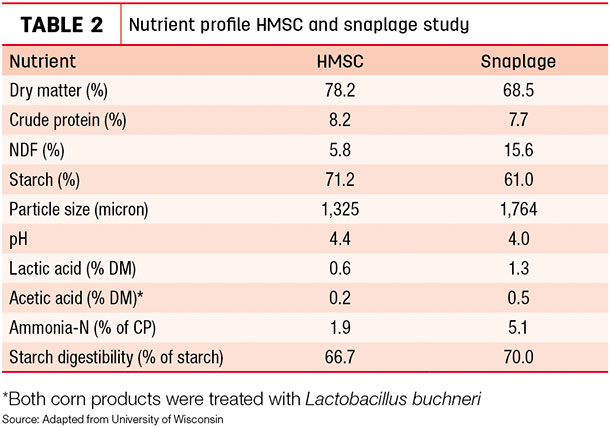

The University of Wisconsin conducted the definitive study. In the study, HMSC, snaplage and snaplage supplemented with dry corn (about one-third of the snaplage dry matter replaced with dry corn on a dry matter basis) were compared. Table 2 compared the nutrient composition along with corn silage for comparison.

Dry matter content was lower for snaplage compared to HMSC. NDF (neutral detergent fiber) was higher, reflecting the inclusion of cob and plant parts. Starch content was lower in snaplage due to NDF addition and was processed coarser.

Using the Penn State particle box, the snaplage percentages were 2 percent on the 19-millimeter screen (reflects plant material), 11 percent on the 8-millimeter screen, 73 percent on the 1.18-millimeter screen and 14 percent on the bottom pan.

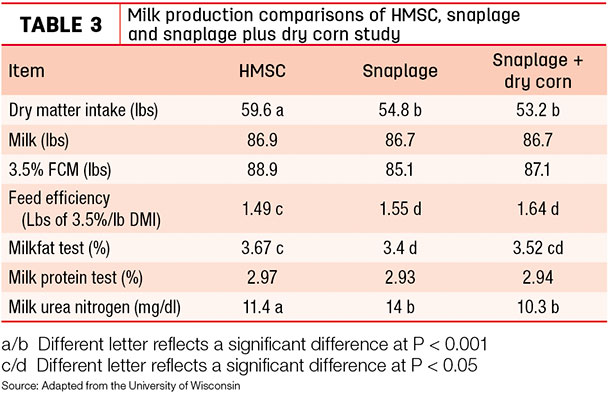

Table 3 reflects milk production responses to the three rations. Dry matter intake (DMI) was highest with the HMSC, but there were no differences in milk yield. Milkfat test was lower with snaplage, leading to lower yields of fat-corrected milk (3.5 percent FCM).

Because similar milk yield was reported with lower DMI, feed efficiency (defined as pounds 3.5 percent fat test milk yield per pound of dry matter consumed) was higher with both snaplage-based rations. The lower dry matter intake with snaplage could reflect higher fiber level and higher degraded starch in the rumen.

Because similar milk yield was reported with lower DMI, feed efficiency (defined as pounds 3.5 percent fat test milk yield per pound of dry matter consumed) was higher with both snaplage-based rations. The lower dry matter intake with snaplage could reflect higher fiber level and higher degraded starch in the rumen.

Significant lower milkfat test could reflect rumen fermentation changes which was partially corrected with replacing snaplage with dry corn. The higher ammonia nitrogen in the fermented snaplage could be related to the wetter fermentation reducing protein in snaplage.

Milk urea nitrogen (MUN) also reflected higher soluble protein in the ration and/or rumen fermentation limitations that could reduce bacterial capture of ammonia as microbial protein. Milk protein percentage did not change.

Snaplage recommendations and field observations

The moisture content of snaplage should target 40 to 45 percent moisture to insure compaction and optimal fermentation.

Avoid separation of corn kernel from cobs and plant material due to differences in density and particle size (especially in upright storage). Pockets of drier plant material can result in mold formation and reduced feed intake.

Wetter snaplage will increase solubilization of the starch and ammonia (reduction in protein encapsuling starch granules), especially when stored over 120 days. Ammonia levels reflect greater degradation of protein. Guard against rumen acidosis risks due to greater rumen-fermentable starch.

Particle size should be coarse to reduce the risk of rumen acidosis and excessive starch fermentation (1,500 to 2,000 average micron size). Kernels should be rolled and appear as a flake (rollers set at 1 millimeter clearance, especially if kernel dry matter is less than 30 percent).

Because of the lower starch level in snaplage and faster rumen fermentation rate, adding dry corn (replacing 10 to 25 percent of snaplage dry matter) may improve dry matter intake, reach optimal starch levels and maintain milkfat test.

Using a silage bacterial inoculant is recommended to enhance fermentation. Snaplage is harvested during cooler times of the fall season when natural bacteria numbers can be reduced. Research suggests Lactobacillus buchneri, a heterfermentative inoculant, can increase acetic acid levels that can slow the formation of yeast and mold development during feedout periods (Table 2).

Determine the optimal snaplage feed rate and size of your storage unit to meet feed removal rates to maintain grain quality. High-moisture corn storage can be a challenge with rodents, coons and birds in plastic bag storage or piles covered with plastic.

An optimal feed-testing program should be considered when feeding snaplage, as quality can change due to hybrid differences related to kernel-to-cob ratio, the amount of plant material captured due to moisture content when harvesting (dew or rain) and differences from field to field. ![]()

PHOTO 1: Earlage harvest progresses on a northeastern North Dakota dairy operation.

PHOTO 2: Earlage is produced with an all-crop header and stored in a bunker silo in southeastern North Dakota. Photos by Greg Lardy, NDSU Animal Sciences.

-

Mike Hutjens

- Professor of Animal Sciences Emeritus

- University of Illinois – Urbana