While the fermentation process in grasses is not too different from crops like corn or alfalfa, maximizing quality and yield in the final silage creates management challenges.

To optimize grass silage fermentation, water-soluble carbohydrate (WSC) levels of 10%-15% are desired. This level of WSC provides energy needed for effective fermentation. Unfortunately, we find that targeting this WSC level can result in ensiling grasses with low dry matter content.

All silages are at risk of costly losses caused by undesirable fermentation (anaerobic losses), secondary heating and molds (aerobic losses), but low dry matter silages (25%-30%) are at particular risk because they create an environment that is especially favorable for clostridial contamination. These undesirable anaerobic bacteria in silage metabolize lactic acid into butyric acid and degrade plant protein, resulting in high amounts of butyric acid and ammonia. Butyric acid formation decreases the dry matter and energy value of the final silage product, and it has been linked to reduced intake for the herd and susceptibility to ketosis for transition cows.

Clostridia can grow faster during fermentation than other undesirable microorganisms, so they are especially difficult to control. The best preventative measure against clostridial fermentation is a fast and deep drop to a pH of less than 5.0 to inhibit clostridia development.

A desirable low pH level is more difficult to achieve in grasses and legumes than in corn, so silage inoculation is a management tool for consideration to prevent clostridial development. A homofermentative lactic acid bacteria (LAB) silage inoculant can quickly produce high levels of lactic acid and drop the pH to a level not tolerated by clostridia.

Studies reveal benefits of inoculants for grass silage quality

Two studies examined the efficacy of a homofermentative LAB inoculant blend to help understand differences in quality measures when compared to an untreated control. These studies showed significant improvement in lactic acid content, lowered pH values, decreased butyric acid and ammonia levels, and increased preservation of silage protein.

Study 1 – This study used three grass materials from different farms with 25%-36% dry matter. Each chopped grass material was ensiled once as untreated control and once treated with a homofermentative LAB silage inoculant blend (Lactobacillus plantarum, Pediococcus acidilactici and Lactococcus lactis).

LAB were sprayed onto the grass at a concentration of 250,000 colony-forming units per gram grass (cfu/g). Silage was placed in laboratory silos (6.5 liters) and analyzed after 90 days of storage at 68°F.

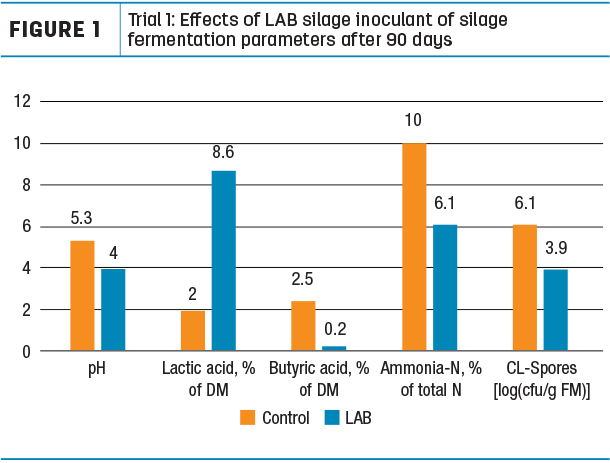

After 90 days of fermentation, both silage treatments had an identical 29.1% dry matter level. Silages treated with a LAB reached a significantly lower pH (4.0) than untreated controls (5.3) (Figure 1).

This is reflected by the much higher level of lactic acid in the LAB-treated silage. The high concentrations of butyric acid and ammonia-N found in the control silage indicates the likelihood of significant clostridia fermentation. High counts of clostridia spores in untreated controls were further evidence.

The LAB additive blend improved silage quality due to production of high amounts of lactic acid and the resulting rapid pH decrease. Significantly lower amounts of butyric acid and a clear tendency toward lower levels of ammonia-N would result in a more palatable and higher-nutrient-content grass silage.

Study 2 – This study used first-cut perennial ryegrass. Chopped grass material (18.1% dry matter) was ensiled as 1) untreated control and 2) treated with the same LAB blend sprayed onto the grass at a concentration of 300,000 cfu/g grass. Laboratory silos (1.5 liters) were analyzed at multiple time points over 90 days of storage.

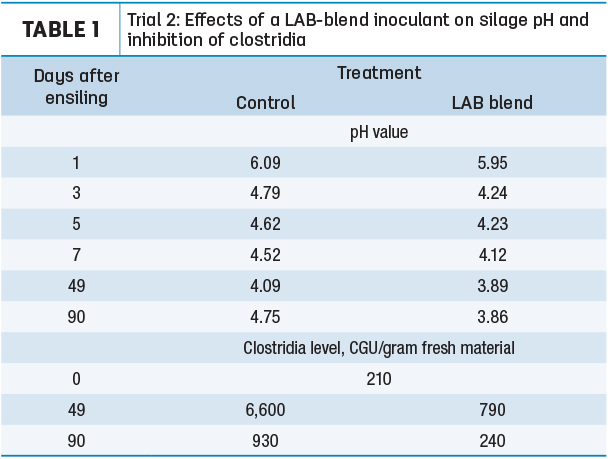

Addition of a LAB blend produced a more rapid pH drop compared to the control (Table 1).

The LAB blend provided a pH of almost 4.0 by day seven, and a final pH of less than 4.0. Control grass silage had a slower pH drop and was not able to maintain the desirable pH at the end of ensiling. Clostridia contamination did increase for control silage and remained higher than the LAB blend at the end of ensiling.

Summary

The objective of silage production is to preserve and transfer nutrients from the field to the feedbunk. The fermentation process – the production of lactic acid and resulting drop in pH – is key to effective nutrient conservation in silage production.

Lactic acid production in silage fermentation must occur rapidly to inhibit the occurrence of clostridia and maintain silage quality. Silages with low dry matter content, in particular, are more likely to resist the necessary lactic acid production, which opens the door to clostridial proliferation.

The managed use of a LAB blend inoculant in grass silage production enhances animal performance as it inhibits clostridia, helps secure silage hygiene, maintains protein quality and allows for maximum palatability and feed intake. ![]()

PHOTO: The managed use of a LAB blend inoculant in grass silage production enhances animal performance as it inhibits clostridia, helps secure silage hygiene, maintains protein quality and allows for maximum palatability and feed intake. Staff photo.

References omitted but are available upon request. Click here to email an editor.

-

Gary Lynch

- Technical Research Manager

- Provita Supplements

- Email Gary Lynch