There are two major causes of reduced forage quality, especially noticed in poor drying conditions: respiratory loss of NFC (sugars and starch) and leaf loss.

Respiratory loss

Respiratory loss occurs because the plant continues to respire (break down sugar and starch to give off carbon dioxide) after being cut until the plant dries below 60% moisture. Alfalfa is generally about 75% moisture when cut, so rapidly losing the first 15% water quickly will reduce respiratory losses. These losses can range from 2% to 8% of the dry matter (DM) and have larger impacts on forage quality. NFC is 98% digestible to animals. Further, loss of NFC increases plant neutral detergent fiber (NDF) and lowers relative forage quality (RFQ).

Most of the respiration takes place in the leaves. Conditioning is important for drying the stems but has little impact on drying the leaves. A wide swath has the biggest effect on rate of leaf drying. Leaves dry faster in a wide swath because:

- Sunlight (even on a cloudy day) has the largest effect on drying. More sunlight falling on the field is intercepted for drying hay in a wide swath. (A windrow intercepts only 25% to 30% of sunlight falling on the field while a wide swath intercepts 70% to 100% of sunlight.)

- Light keeps the leaf stomates open longer, so moisture can leave through leaf openings. Most of the forage in a windrow is in the dark, so leaf stomates close to seal the leaf between surface wax layers, reducing drying rate.

Pull-type or triple mowers are recommended rather than self-propelled mowers because the latter can only make windrows narrow enough to fit between the wheels. The windrow utilizes less than half the sunlight falling on the field. Some are worried about bleaching losses in a wide swath, but bleaching only occurs when the leaves are dry, so make a wide swath and then merge into a windrow after 16 or 24 hours (when leaves are nearly dry). A wide swath can reduce hay drying time by one day or more.

Additionally, the slower drying and delayed hay removal from the field can reduce next-cutting yield (due to driving over alfalfa regrowth and, possibly, delayed irrigation).

Leaf loss

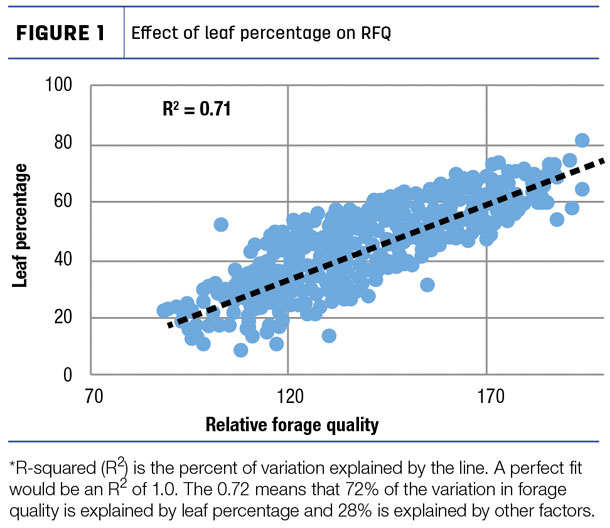

Leaf loss during harvesting is a major unrecognized loss of yield and forage quality. Leaves are 15% to 20% NDF, while stems are 60% to 70% NDF. Thus, RFQ is closely related to stem content of alfalfa, as shown in Figure 1.

Some of our studies indicated that some farmers were losing up to 30% of leaves during harvesting. Alfalfa harvested at the bud stage is generally 45% to 55% leaves. I encourage you to look at your hay to determine how close to 50% leaf content your harvested hay is. If your hay is much below 50% leaves, consider the following: Every time you move the forage prior to harvest results in a leaf loss.

Some of our studies indicated that some farmers were losing up to 30% of leaves during harvesting. Alfalfa harvested at the bud stage is generally 45% to 55% leaves. I encourage you to look at your hay to determine how close to 50% leaf content your harvested hay is. If your hay is much below 50% leaves, consider the following: Every time you move the forage prior to harvest results in a leaf loss.

- Try to rake/merge only, as each operation results in additional leaf loss, e.g., tedding, windrow inverting. No additional operations should be necessary if starting with a wide swath but are often required in poor drying conditions when starting from a windrow.

- Wetter forage results in less leaf loss when moved. So rake/merge when forage is above 40% moisture if possible.

- Rolling forage across the ground results in leaf loss. Reduce distance moved by raking to the middle with a large rake rather than to one side.

- Mergers generally result in less leaf loss than rakes since they pick up the forage and move it on a conveyer belt. (Though data has shown that rotary rakes may have similar leaf loss for making haylage.) Further, consider the ground speed of the merger relative to pickup speed – is the merger pickup throwing leaves ahead of the swath as it is being picked up?

Recommendations

Thus, a recommended procedure would be to mow, place alfalfa into a swath covering 80% or more of the cut area, rake/merge when at 40% to 60% moisture and harvest. In the Midwest and Northeast, haylage made with wide swaths can often be harvested the same day it is cut. In the West, hay can be harvested in two to three days rather than five to seven days.

Lastly, minimize leaf loss during baling or chopping. Harvesting windrows that are near capacity of the baler or chopper is more efficient in terms of fuel and labor. The larger windrow also results in less leaf loss at the harvester pickup during harvest.

Newer medium and large square balers tend to have less leaf loss than older small square balers because the newer balers feed straight through to the bale chamber while small square balers tend to auger or rake the dry hay across the machine width to a bale chamber.

Also look behind the baler: Is there a layer of leaves falling on the ground? Also consider what is falling through the belts of a round baler. Note that making baleage rather than dry hay with round balers will result in less leaf loss (higher yield and forage quality).

When chopping alfalfa, is there a green cloud around the chopper wagon or truck? Is green “dust” being blown out of the wagon or truck? Each of these would indicate leaf loss during the chopping process. We have measured up to 28% of the leaves being lost during harvesting for haylage – more than I ever thought possible.

A little toughness on the hay/haylage at baling or chopping may reduce losses; harvesting dried hay overnight or in the early morning with dew (as is often done in the West) can reduce yield and quality losses. This approach may also be beneficial for those harvesting haylage.

Standing alfalfa will normally have about 45% to 55% leaves at the bud stage. Leaf loss cannot be eliminated; it can, however, be minimized. By paying attention to “harvesting leaves” rather than “harvesting hay,” one can observe where leaf loss is occurring in your operation and take steps to reduce losses. In some cases, different machinery may be called for but, in many cases, equipment adjustment and timing of use may significantly reduce leaf loss. ![]()

-

Dan Undersander

- Forage Professor Emeritus

- University of Wisconsin