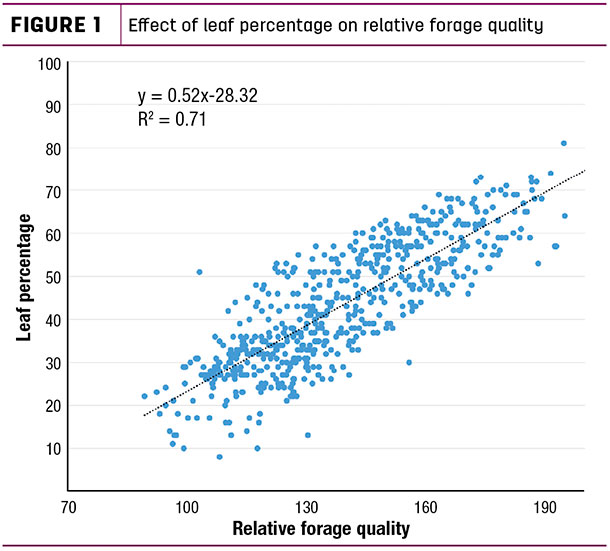

Thus, if we want quality forage, we must focus on harvesting leaves. Figure 1, from a study of four rake types in three states, shows leaf percentage accounted for 71 percent of variation in forage quality.

It was more important than maturity or any other factor.

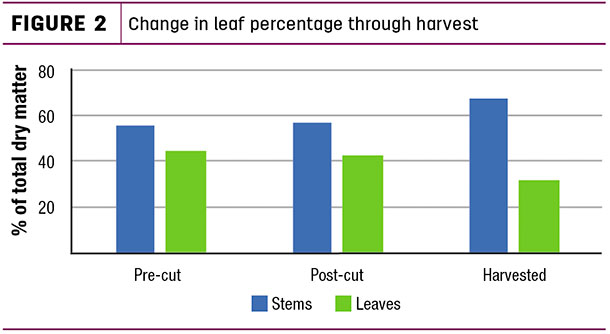

If alfalfa is growing normally, it will have about 45 to 55 percent leaves when it is harvested at the bud stage. This shows up in Figure 2 when interns in a Winfield program monitored some fields from before mowing through harvesting.

This field averaged about 45 percent leaves in the standing alfalfa before cutting; the leaf percentage fell about 2 percent through mowing and conditioning and then fell dramatically in the harvesting process (about 13 percent).

This field was harvested for haylage, where we would expect fewer losses than when alfalfa is harvested for hay, yet the average loss during harvesting was about 40 points relative forage quality. This was due to leaf loss, which went from 45 percent of dry matter down to 32 percent of harvested forage. Note the leaf loss also resulted in a 16.5 percent yield loss during harvesting.

What can be done to minimize leaf loss? Consider the following: Evaluate alfalfa stands – did you start with 45 percent or more leaves or did many fall to the ground prior to mowing? If the latter, especially under cool, wet conditions, first determine if all varieties showed the same leaf loss; some varieties have more leaf disease resistance than other varieties and should be considered for future planting.

Also, considering an application of fungicide to reduce leaf diseases and leaf drop at early regrowth stages may be beneficial. Evaluate carefully, as fungicide is an expense that can be beneficial but may not always be needed.

Check after mowing and conditioning. Generally, we have seen small leaf loss at this stage, but the following should be kept in mind:

1. A flail/impeller conditioner will result in increased leaf loss of alfalfa compared to a roller conditioner or no conditioner.

2. Placing alfalfa into a wide swath after mowing will enhance drying rate and reduce non-fibrous carbohydrate loss. Non-fibrous carbohydrate is 98 percent digestible to animals. The loss also results in a drop of relative forage quality.

For larger operations, we are recommending triple mowers rather than self-propelled mowers because the latter only make windrows narrow enough to fit between the wheels. The yield loss of these windrows can be significant from respiration during drying (up to 8 percent of dry matter) and from delayed hay removal from the field that can reduce next cutting (due to driving over alfalfa regrowth and delayed irrigation).

Every time you move the forage prior to harvest results in leaf loss.

- Wetter forage results in less leaf loss when moved. So rake or merge above 40 percent moisture if possible.

- Try to rake or merge only, as each operation prior to harvest results in additional leaf loss (e.g., tedding, windrow inverting).

- Rolling forage across the ground results in leaf loss.

- Move forage to the middle with a large rake rather than to one side to reduce moved distance and rolling of hay.

- Mergers result in less leaf loss than rakes since they pick up the forage and move it on a conveyer belt.

- Thus, a recommended procedure would be to mow, place alfalfa into a swath covering 70 percent or more of the cut area, rake or merge when at 40 to 60 percent moisture, and harvest. In the Midwest and Northeast, haylage made with wide swaths can often be harvested the same day it is cut. In the West, hay can be harvested in two to three days rather than five to seven.

Minimize leaf loss during harvest. If the windrow is a size near capacity of the baler or chopper, then harvesting is more efficient in terms of fuel and labor. The larger windrow also results in less leaf loss at the harvester (either baler or chopper) pickup during harvest.

Also look behind the harvester: Is there a layer of leaves falling on the ground behind the bale chute, from between the belts of a round baler or is there a green cloud around the chopper wagon or truck?

Each of these is a sign of leaf loss that results in reduced harvested forage yield and quality. A little toughness on the hay/haylage may reduce these losses; this is why harvesting hay dried overnight or in the early morning with dew can reduce yield and quality losses. This approach may also be beneficial for those harvesting haylage.

Leaf loss cannot be eliminated; it can, however, be minimized. By being sensitive to the concept of “harvesting leaves” rather than “harvesting hay,” one can observe where leaf loss is occurring in the operation and take steps to reduce losses. In some cases, different machinery may be called for but, in most cases, equipment adjustment and timing of use may significantly reduce leaf loss. ![]()

-

Dan Undersander

- Forage Specialist

- University of Wisconsin

- Email Dan Undersander