Many of us are either just opening 2022 corn silage, while some have already begun feeding this season’s corn silage harvest. Traditionally, new crop corn silage can be temperamental in how it feeds, and it can be especially finicky in letting go of its starch content. No one likes washing down corn in the parlor or spreading corn-laced manure in the field to feed the turkeys.

Much research has been done looking at the “fall slump” with corn silage, largely related to reduced starch digestibility of unfermented corn silage. In a perfect world, producers would have a corn silage carryover of at least three months, in an effort to feed fermented corn silage year-round, but as in life and with forage, not all things happen as planned.

We have all experienced a forage that did not “feed” like it should or read properly on the forage test. My grandfather would often compare a stubborn forage to trying to find that break in the electric fence without the help of a noticeable spark or the familiar “tick, tick, tick.”

When we face this, there are some practices and analytics we can lean on to dial in and unlock the true value of the forage.

Tried and true

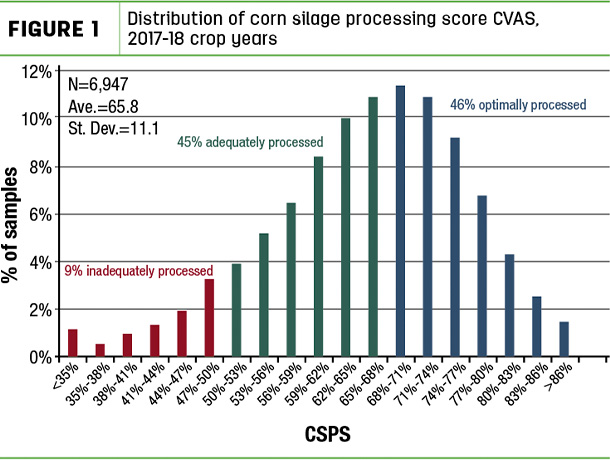

Often we can look to the obvious cause of starch availability issues, such as corn silage processing score (CSPS). This common lab practice using a Ro-Tap Shaker is the best way to monitor your corn silage kernel processing. Typically, this is done after harvest due to lab processing time. CSPS goals are more than 70% of the kernels passing through a 4.75 millimeter screen (see Figure 1).

More timely procedures at harvest include floating corn silage or using a 32-ounce cup of freshly chopped corn silage to monitor kernels that are preferably quartered. The goal for kernels in the cup is to be less than two whole kernels per cup. Cornmeal can also be part of the puzzle that is often the last piece to solve as it is often purchased and processed by the feed mill with little control at the farm level. Analyzing cornmeal processing with a micron screening test can often be an informative undertaking.

Backend biology

The Aug. 25, 2021, edition of Progressive Dairy had an in-depth article on backend biology, which is how manure screening pertains to rumen health and milk production. Routine manure screening can build a benchmark that can assist in identifying changes in both fiber and starch, as well as rumen function. Then, we can correlate with the Penn State Shaker Box in an effort to see a metric prior to intake and post-cow.

The manure of a cow can tell us a lot about what is going on with starch and fiber digestion. Fecal starch testing is an under-utilized tool in the forage analytic toolbox. Collect fresh, uniform manure samples from at least 10 cows, mix them together and send them overnight on ice to your favorite testing lab. The reason for the timely test and cool temperatures is to have a realistic measure of actual on-farm fecal starch, as bacteria in the manure will break down that fecal starch, leading to an underestimation of fecal starch.

The traditional goal for fecal starch levels has been under 3%, while more modern goals are to be under 1% fecal starch. The importance of a fecal starch measure is that each percent of fecal starch equals 0.72 pounds of lost milk production. But the loss does not end there, as you can measure the lost starch in relation to cornmeal and undigested feed. These can add up to very large losses in income for the herd over the year. There is a direct correlation of fecal starch to kernel processing score. This is where combining different tools can really start to crack the case.

Next-level analytics

To this point, we have looked at some external ways to troubleshoot forage issues. Another important aspect is to look internally at how a forage is digested. One option gaining popularity is in vitro fermentation analysis of total mixed rations (TMR). The practice of monitoring TMR and forage kinetics via rumen fluid and simulated rumen function has been available for a while and is really gaining traction.

Looking at an in vitro fermentation model (IFM, Alltech), we can monitor fermentation of starch, sugar and fiber as well as total ration digestibility and microbial production. These parameters show the rate of digestion of the grain portion of the TMR and how quickly, or slowly, forages ferment in rumen fluid. We can also see the interaction between protein and carbohydrate degradability as well as the total energy potential of the TMR.

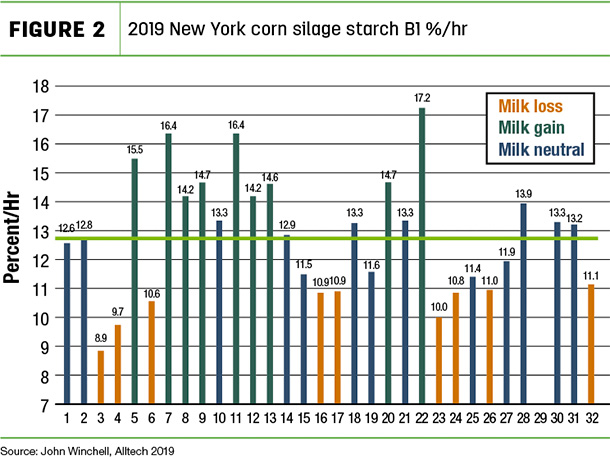

Another alternative use for the IFM that is catching attention is evaluating individual forages. For example, this can unearth how well a corn silage will feed in the fall. Figure 2 represents fresh corn silage samples from 2019 in New York.

Starch pool rate of degradation fluctuates by sample and can help predict starch digestion of fresh corn silage post-harvest. The slower the rate of degradation of the starch pool, the more likely there will be a milk loss with this corn silage sample. The faster the rate, the more likely the starch in the corn silage is more available at harvest. Fresh corn silage samples taken in 2019 show the variation in how available the starch is and how those samples translated to either increased or decreased milk production.

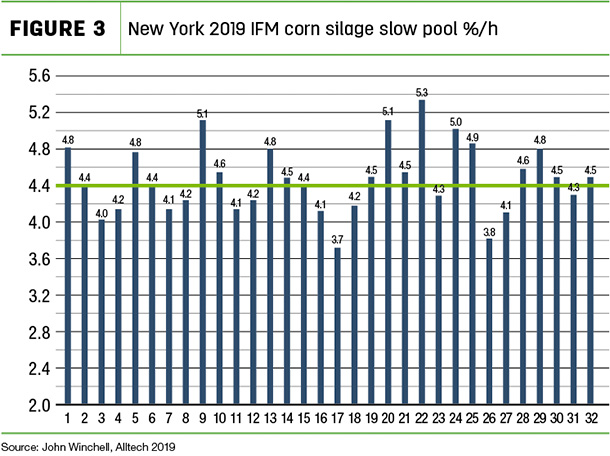

From the fiber digestibility side, we can also look at the slow pool rate to get an idea of fiber digestibility (Figure 3).

Often times these individual differences are a result of environmental relationships, soil type, fertility, variety and overall plant stress.

Between looking at individual forages and TMRs, we can begin to uncover information to put the puzzle together and then decide how to solve the puzzle. In the fall, nutritionists will use different methods in an effort to unlock corn silage. Quickly degrading starch and sugar sources, soluble fiber sources and amylase enzymes are often used to compensate for slow starch digestion in fall forages. On-farm forage tools give us more information and direction on how to navigate the bumpy waters of forage change and help us get a jump on making the right moves to keep the consistency our cows love.