Micro-irrigation, also known as drip irrigation, is the fastest-growing irrigation technology in the world. It was commercially introduced in Southern California more than 40 years ago to help irrigate crops in challenging terrain and with limited, expensive water supplies.

Now, a specialized sub-set of drip irrigation called subsurface drip irrigation (SDI) is routinely installed on field crops, such as alfalfa, corn and cotton.

In SDI applications, dripline or drip-tape “lateral lines” (tubes buried beneath the crop rows) and supply and flushing “submains” (pipes supplying water to the lateral lines) are buried beneath the soil surface for multi-year use. This technique of burying less-expensive bi-wall drip-tape laterals beneath field crops was pioneered in the American Southwest decades ago and has since been widely adopted worldwide.

Producers claim common benefits of SDI include yield increases, crop quality improvement and better resource use efficiency along with improved flexibility, convenience and the ability to farm in drought conditions.

In contrast to gravity, sprinkler or pivot irrigation, SDI systems deliver water and nutrients directly to the soil and roots at low pressure and flow rates, and typically operate at frequent intervals of varied duration.

Unlike pivot irrigation, SDI systems can accommodate a wide range of block sizes, shapes and flow rates, making it possible to irrigate irregularly shaped fields or field corners.

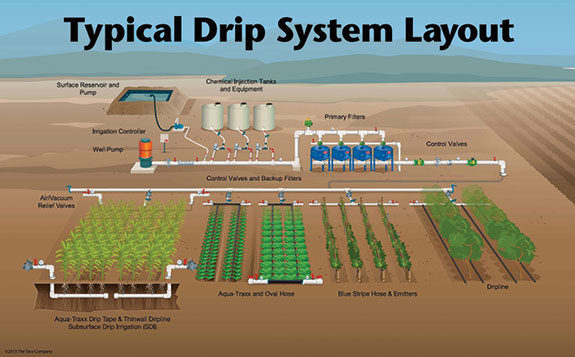

In addition, SDI systems allow easy access to the field for cultural operations, even during irrigation. Although every system design will be different, the following image provides a good starting point for typical drip system layouts for SDI, row crops, vineyards and orchards.

Case studies

Bob Thomas and his son, Rob, farm 360 acres of alfalfa under drip in California’s Imperial Valley near Seeley. Thomas reports that SDI allows them to flat-harvest, which reduces harvest costs, and that the reduced dry down time before and after harvest improves crop vigor.

In addition, scalding is avoided during summer irrigations, and weed growth is reduced since the soil surface remains dry.

“During the first season we found that we were harvesting 2 tons of alfalfa per acre foot of water applied with SDI versus 1 ton per acre foot of water applied via flood irrigation with borders,” says Thomas.

Ken Seim of Grand Island, Nebraska, has farmed 1,400 acres of corn and soybeans for more than 35 years, and as of August 2012, Seim reported that in addition to 3.5 inches of rainfall, he had only applied 9 inches of water to his SDI field to achieve the same yields as the field where he had applied 20 inches of water with a center-pivot irrigation system; his gravity fields received 22 inches of water.

“I believe that efficient subsurface drip irrigation is the future of irrigation,” says Seim.

Seim’s neighbor, Don Anthony of Lexington, Nebraska, has farmed 1,300 acres in the Platte Valley for more than 40 years using gated pipe, pivots, and now SDI.

He uses two-thirds to three-quarters of the water and energy with SDI versus a center pivot. “If 1 inch of water is applied via a pivot, only 0.6 inches is beneficially or effectively used by the plant,” says Anthony. “Drip is more efficient.”

He also appreciates the system’s ability to quickly irrigate the entire field. “With drip, I can ‘play chicken’ with the weather and sometimes take advantage of a rainfall event that I couldn’t otherwise.”

Loyd Jordan is a third-generation farmer who cultivates 3,500 acres southwest of Lubbock in Terry County and Lynn County, Texas. He irrigates 1,250 acres with pivots and, most recently, 300 acres with subsurface drip irrigation.

A neighbor had tried drip and said good things about water savings, getting increased yields on fewer acres, and how easy it was to apply fertilizers and control insects. So in 2004, Jordan installed 40 acres.

He liked it so much that he installed an additional 120 acres in 2007, and then another 140 acres in 2009. Now, he prefers drip to the pivots he used for so many years. “I can get 3 bales of cotton per acre with 16 inches of drip water, but only 2.25 bales per acre with 16 inches of pivot water,” says Jordan.

Factors for success

SDI systems are expected to last for many years. As a result, they must be designed, installed, operated and maintained properly.

The choices of laterals, submains, accessory equipment and application rate depend on many factors including soil type, water conditions, cultural practices and field size, shape and topography. Low application rates are often selected in order to reduce overall system cost.

Common challenges include emitter clogging, root intrusion, vacuum suction and insect, rodent and mechanical damage – all of which may be successfully addressed with proper planning and management.