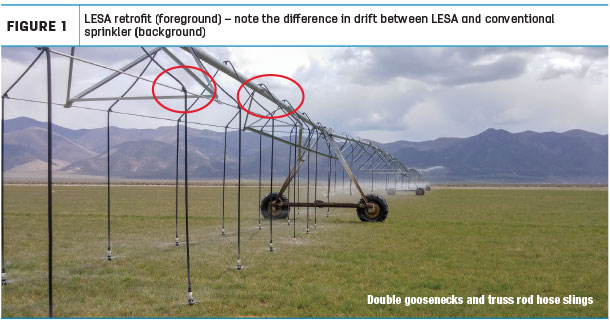

A typical installation is shown in Figure 1.

In this type of installation, where the sprinkler heads are located about 12 to 15 inches above the ground, water savings have been shown to range from 15 to 20-plus percent in longer-season crops like alfalfa or silage corn.

To retrofit a machine with an outlet spacing of 9 to 10 feet involves using a double gooseneck to narrow sprinkler spacing to 4 to 5 feet (Figure 1). Many newer machines have outlets spaced from 30 to 60 inches, so the double gooseneck will not be needed.

Sprinkler heads are changed to spray heads with grooved spray plates, and a 10-pound-per-square-inch pressure regulator is normally used. A minimum of a 1-pound weight per drop is required, with a greater weight necessary if conditions are extra windy.

It is not currently recommended to convert the first one or two spans out from the pivot point since nozzle size would be very small (with a higher probability of nozzle plugging), and the area and water involved are a small fraction of the whole pivot.

In the standard sprinkler arrangement, with a nozzle height of 5 to 7 feet above the ground, sprinkler spacing greater than 5 feet (mostly 10 feet or greater) and sprinklers with a 40- to 45-foot wetted diameter, water can be lost due to evaporation and wind drift as droplets fall from the sprinkler heads to the ground. An additional loss occurs as some water is caught on plant surfaces and evaporated before it reaches the ground. Wind drift increases this loss as water is spread over a larger canopy area.

In contrast, with the lower sprinkler head placement in LESA systems, water is released closer to the ground where wind velocity is noticeably lower and droplet travel time to the ground is reduced, resulting in less evaporation and wind drift.

Also, when crop height is greater than sprinkler height, the loss component due to evaporation from plant surfaces is reduced, since most water is released in-canopy. Reduced pivot track rutting is another benefit observed at some sites. Use of a mounting bracket to locate sprinkler heads behind the towers can more consistently reduce rutting.

Does LESA fit your operation?

LESA is particularly well suited for alfalfa production since several irrigations for each cutting occur when the crop is re-growing and shorter than sprinkler height. During this time, water is spread evenly with no impediment over a roughly 16-foot wetted diameter. Once the sprinklers are in-canopy, plant stems block or deflect water, resulting in most water application occurring within 2 feet of the sprinkler.

If the portion of the growing season with sprinklers in-canopy is relatively large, say for a grain crop, reduction in the uniformity of water distribution can result in bands between sprinklers that receive significantly less water which can initiate crop water stress and potentially impact crop yield and quality.

This has been observed in grain and potatoes but not in alfalfa. Work in Idaho in 2017 indicated further reducing sprinkler spacing to three drops per 9- to 10-foot outlet spacing provided good water application uniformity for potatoes and spring barley.

Runoff risk from LESA due to concentration of applied water in a smaller area has been significantly lower than anticipated, with very few locations having documented problems. Care should be used in retrofitting a pivot to LESA in soils that have experienced runoff problems with conventional sprinklers. In these cases, perhaps installation of one span of LESA as a test would be a safer alternative to initially converting the entire machine.

For a LESA retrofit to make sense in a specific situation, LESA must work for all crops in the grower rotation. LESA has been tested in Nevada, Idaho, Montana, Washington, Oregon and California over the last four years with successful results in almost all cases. Crops tested include alfalfa, oats, spring grain, corn, mint, grass seed, grass hay, irrigated pasture and potatoes.

Current recommendations:

- Relatively flat fields with few humps or ridges, no potatoes in the rotation and grain infrequently used as a nurse crop and maximum water savings desired:

o Sprinklers in-canopy, with 12- to 18-inch height above the ground at maximum annual tire track rutting depth

o Sprinkler spacing of about 5 feet

- Potatoes or frequent grain in the rotation, or more rolling land and maximum water savings desired:

o Sprinkler spacing at roughly 3 feet will provide reasonable water application uniformity when heads are dragging across ridges, etc.

o Sprinklers in-canopy, with 12- to 18-inch height above the ground at maximum annual tire track rutting depth

- Potatoes or frequent grain in the rotation, with concern about dragging sprinkler heads through a potato canopy (disease spread concerns) or more rolling land and some water savings desired:

o Sprinklers about 40 inches above soil to clear potato vines and drops spaced about 5 feet

o Lower cost but less water and power savings. A 17 percent reduction in measured groundwater pumping relative to an adjacent conventional pivot with equal malting barley yield and quality was observed at one site in 2017.

Selection of the most appropriate LESA configuration depends on the site-specific conditions listed above and must be a balance between cost and benefits such as water saved, potential disease reduction and reduction in wheel track rutting. Three typical configurations are listed below:

- LESA with heads 12 to 18 inches above ground, 3 to 4 feet spacing, water application efficiency of about 95 percent; upgrade cost about $12,000

Application efficiency is the fraction of the water applied by the pivot that is stored in the soil for future use.

- LESA with heads 12 to 18 inches above ground, 4 to 5 feet spacing, water application efficiency of about 92 percent; upgrade cost about $8,500; risk of streaking on dense canopy crops

- LESA with heads 36 to 42 inches above ground, 5 feet spacing, water application efficiency of about 90 percent; upgrade cost about $8,000

Reduction in water pumped is compared to the current systems which will generally have water application efficiency of about 70 to 85 percent. The 85 percent value can be obtained under low or no wind conditions. However, as wind velocity increases, the application efficiency will be reduced and can go as low as 50 percent on a very hot, windy day.

In summary, retrofit of a conventional pivot to LESA configuration is an alternative that can reduce water pumping by around 15 to 20 percent for forage or pasture applications on appropriate soils. It does not apply in all conditions and is not a “one size fits all” solution for reducing pumping quantity or cost.

The specific equipment arrangement will depend on cost versus benefit considering the desired level of pumping reduction. If in doubt, start small, with maybe one span, and observe for problems and potential solutions. The span just before the last tower will give the most severe test for runoff concerns. ![]()

Project support provided by Bonneville Power Administration, Anheuser Busch and USDA-NIFA.

-

Howard Neibling

- Extension Water Management Engineer

- DaUniversity of Idaho

- Email Howard Neibling