It’s not as simple as round bale versus square bale

Round, large square, small square, wrapped or unwrapped – no matter how you package it, it’s still hay. What matters is whether it maintains forage quality, is the size best suited for handling in a specific situation and minimizes production cost.

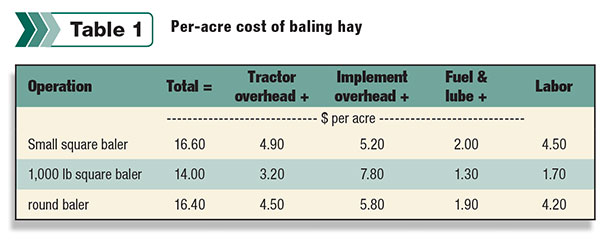

In 2003, University of Illinois researchers Schnitkey, Lattz and Siemens estimated costs for owning and operating forage machinery (see Table 1), based on an average 1.3-ton yield per acre.Granted, costs have changed since then, but comparisons are likely similar.

So deciding on what type of baler to buy comes down to these questions: How fast do I need to bale (considering humidity, drying time and weather)? What size do my customers need? What equipment do I already have (what are the horsepower requirements)? What are my storage or transportation options?

You can make any system work; you just have to be aware of the advantages and disadvantages of each.

Baler cost

Although we have to address equipment cost, it’s not a great idea for you to start there in your purchase assessment. While the price tag on a round baler is typically less than that of a large square baler but more than a small square baler, that’s not the whole story.

Density matters. In a study by University of Kentucky researchers, large square balers were found to make a denser bale (200 kg per cubic meter) desirable for dryer hay harvest and achieve 23 percent less harvesting cost compared to round balers (140 kg per cubic meter).

The equipment price tag is only one part of a multi-part equation, and must be balanced with operation costs, storage costs and transportation costs.

While one baler may be less expensive than another coming off a dealer lot, transportation for that bale configuration may be higher, or leaf loss may be higher, or the market may be looking for a different size. So the sticker price certainly shouldn’t be the sole determining factor in a baler decision.

Reducing harvest loss

Once hay is cut, dry matter can only decline. Harvest losses range as low as 10 percent for grass hay to as high as 35 percent for legumes.

While small square balers used on alfalfa generally experience 1 to 5 percent loss, under the same conditions losses register 3 to 30 percent for large round balers.

These elements contribute to potentially high loss but can be minimized with proper management – moisture content, baler pickup design, bale chamber action and bale movement to storage.

Hay moisture content is the largest single factor contributing to leaf loss, where the highest nutrients are stored. Baling at the proper moisture for bale size is critical to leaf retention.

Pickup mechanism

Losses as high as 12 percent can happen in the baler’s pickup mechanism. Field speed, size of windrow, hay moisture content and condition of the pickup mechanism can influence this loss.

If the operator is running too fast, hay is jammed into the pickup mechanism. If the operator runs the baler too slow, the pickup teeth “snatch” the hay from the windrow, breaking it apart.

Optimally, the speed should be such that the windrow is gently lifted and “flows” into the bale chamber with minimum disruption.

Bale chamber

Bale chamber losses can account for as much as 18 percent, due to windrow size, field speed, moisture content, rotating speed and wrapping. Feeding the chamber quickly results in less chamber loss.

Thus, accepting more leaf loss on the pickup to quickly fill the bale chamber may constitute an acceptable trade.

Bale transportation

Between 1 and 10 percent yield losses can occur when round bales are moved from field to storage. If bales can be moved soon after baling, before they begin to lose shape and wraps or ties begin to deteriorate from UV exposure, the loss can be minimized.

Making dense bales will also improve shape, so bales sag less, thus reducing loss.

We can talk about knotters or netwrap, round or square, belts versus chains and pickup width, or cost all day long. But every option must address three questions: How fast can I bale? Will the baler perform reliably so I can get my hay up at the right moisture? Will I have good dealer support? FG

References omitted due to space but are available upon request. Click here to email an editor.