However, even the purchase of less costly, used machinery should be managed responsibly.

There are numerous reasons you may be considering the purchase or replacement of a piece of machinery or equipment, including age, obsolescence, capacity, reliability and cost minimization. For instance, is your current machine too small for your needs? This can lead to labor inefficiencies and timeliness or quality issues. Or is your current machine too old for the job? This can lead to breakdowns, which result in more timeliness problems and soaring repair costs.

As a business owner, when making machinery purchase or replacement decisions, your goal is to balance costs with efficiency and performance. Knowing your costs, or estimating expected costs, is the starting point for purchase and replacement decisions.

Understanding machinery costs

Equipment and machinery costs are categorized as either ownership or operating expenses.

Ownership expenses are fixed costs which result from owning the machinery and include depreciation (a non-cash expense), interest, taxes, insurance and housing. Depreciation is the expense resulting from use, wear and age of the machinery. For machinery purchased new, depreciation occurs at a greater rate during the first few years of a machine’s useful life. A less frequently discussed ownership expense is housing, or storage. Investment in proper housing facilities can significantly impact both other ownership costs (depreciation) and operating expenses, specifically repair costs.

Operating expenses are variable costs incurred from operating the machinery and include repairs, labor, fuel, lubrication (oil), and miscellaneous materials and supplies. Machinery operating expenses are substantial, and controlling them is important. Repair costs dominate the operating expense category. Increasing age and total accumulated usage of machinery increases repair and maintenance expenses.

Frequent breakdowns could occur without routine and proper maintenance, preventing machinery from being fully utilized. Labor inexperience can be costly as well, through decreased field efficiency, increased repairs and overall lack of timeliness.

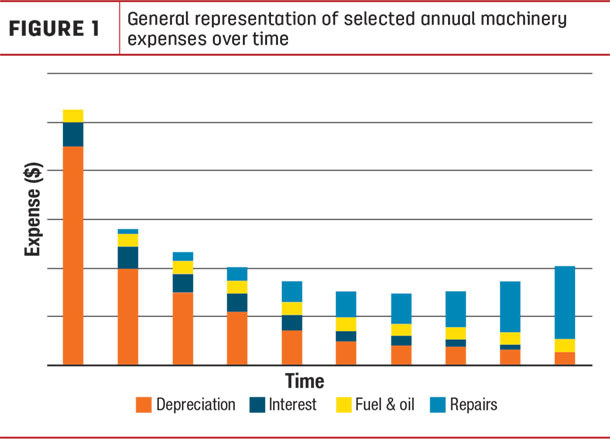

Figure 1 illustrates the general relationship of some select ownership and operating expenses over time for a new piece of machinery.

As you can see, depreciation expense starts out high and quickly decreases. On the other hand, repair expenses are minimal at first, increasing over time as machinery ages and wear-and-tear take their toll. Additionally, you can see the point at which total annual costs are at a minimum.

Understanding machinery costs allows you to make more informed replacement decisions. Keep in mind that actual operating costs can vary quite a bit from operation to operation and year to year depending on maintenance and operating conditions. While you can estimate machinery costs using worksheets or spreadsheets available from your state cooperative extension, maintaining accurate records of your costs is preferable.

Purchase and replacement strategies

At the time of purchase or replacement, you’ll be weighing options such as whether to buy new or used, what size or capacity to purchase, and what level of new technology to invest in.

Repair, maintenance and labor challenges can lead to mismatched decisions regarding capacity. Acreage and machinery need to be matched; excess capacity is simply money out of your pocket in terms of ownership costs. Do you have enough acreage to spread your fixed ownership costs so that your costs per acre are reasonable? Spreading fixed costs over more acres lowers cost of production and increases return on investment.

For technological features you have the ability to make choices on whether to include with a new machinery purchase, evaluate the degree to which additional, improved or more detailed data or precision will improve yields or decrease input expenses.

With a strong understanding of machinery costs and factors that impact those costs, you can determine a purchase or replacement strategy that fits with the overall goals for your farm business. Machinery replacement strategies include:

-

Keep and repair. For operators with mechanical expertise, retaining machinery for the long haul with a focused maintenance and repair program may be a desirable strategy. There is always the risk, though, that the machinery may fail at a critical time, adversely impacting planting or harvest.

-

Trade routinely. Employing a routine trade schedule is a strategy for operators who wish to avoid the inconveniences of age- or high-use-related repairs. While routine trading offers the advantages of minimizing repair expenses and allowing access to emerging technologies, it comes with the downside of consistently higher ownership expenses. If pursuing this strategy, spend time comparing the options of leasing, rollover and traditional purchase.

-

Annual replacement. This strategy sees the operator replace one or two pieces of machinery or equipment annually and can be viewed as something as a middle ground between the two previous strategies. Machinery is held onto longer than under a routine trade strategy – thus requiring investment into repair and maintenance – but not so long as to risk obsolescence or costly and critical breakdowns.

- Replace when income is high. A final strategy is to purchase or replace machinery in years when income is high. This allows you to avoid taking on excessive debt, thereby lowering future interest expense. The challenge with this strategy is: When income is unpredictable, or when you experience prolonged low product prices such as the dairy industry is experiencing, you risk being unable to replace an undependable piece of machinery, which can further harm the business.

Individual management preferences at the farm operation will impact and determine the most appropriate purchase or replacement strategy for the farm operation. This is not the time to look at what your neighbor is doing. The keys to successfully managing a purchase or replacement decision are to understand costs and how they accumulate over time and to know your business’s financial goals. ![]()

-

Sarah Cornelisse

- Sr. Extension Associate Department of Agricultural Economics, Sociology and Education

- Penn State University

- Email Sarah Cornelisse