Here are 10 tips to follow when taking your farm equipment out of storage:

1. Schedule a certified maintenance inspection (CMI)

It’s not too late to take advantage of preseason inspections. This is a great place to start as you gear up for spring. CMIs are a proven and effective way to prevent downtime, protect your equipment investment and improve resale value. Many equipment dealers offer preseason inspection programs, which can help you save money as well as downtime in the spring.

During the maintenance inspection, your dealer’s trained and experienced technicians can spot important maintenance issues before they become costly repairs. They’ll inspect your equipment and provide recommendations on how to maintain your machine for peak performance.

CMIs are well documented and provide valuable service records for the equipment owner. Documented inspections can increase the equipment’s resale value because equipment that has had annual CMIs done will hold its resale value better than equipment that hasn’t.

2. Cleanliness is key

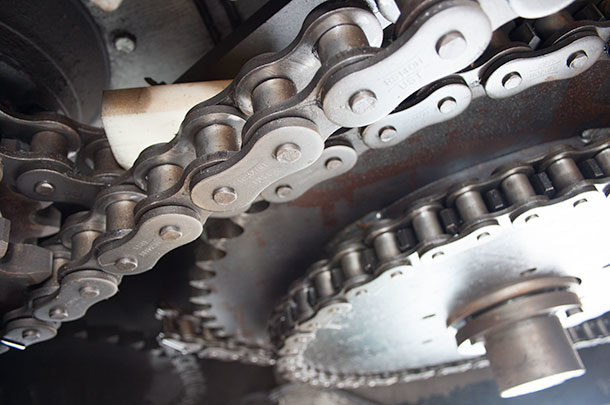

Check equipment for clogged grease points or lack of grease on moving parts and joints that can cause accelerated rate wear and premature failure. Don’t forget to clean engine compartments and heat exchangers of dirt and debris.

3. Touch up paint

This is a good time to apply touch-up paint to scratched or corroded areas. Properly maintained equipment that looks good will command a higher sale price or trade-in value when you decide to replace it. You might also want to follow up with a good wax job. That will help protect your equipment from corrosion and oxidation.

4. Check all fluid levels

This will prevent slow leaks and expensive failures. When you’re replacing fluids and oils, start by checking out your operator’s manual and follow the recommended fluids and service intervals. The engines and transmissions used on today’s farm equipment have been engineered for much higher performance with minimal emissions. So it’s especially important to use fluids that have been specifically designed for your equipment and recommended by the manufacturer and your equipment dealer.

While we’re talking about fluids, this is also a good time to take advantage of fluid analysis tests, which ensure you are running in peak condition by providing a comprehensive evaluation of your machine’s health. Testing vital fluids helps you know what’s going on inside your equipment and can keep minor issues from turning into major problems. The analysis is conducted with small samples of the equipment’s engine oil, transmission oil and coolant, which are sent to a lab for testing. The tests identify the overall condition of the fluids and detect any contaminants. With this information, you’ll get a heads-up on a wide range of equipment conditions, so you can address performance or wear issues before you’re faced with a costly failure. For example, if fuel is detected in engine oil, the report will recommend checking fuel injector performance and changing the oil, depending on the amount of fuel found. The reports include maintenance recommendations based on what has been flagged in the analysis.

5. Connect batteries and check their ability to hold a charge

Keeping your batteries at a full state of charge during dormant periods is the key to preventing discharge and fighting sulfation, a buildup of lead sulfate crystals that is a prime cause of battery failures. Other causes of battery failure include vibration, contamination, damaged charging plates (due to overheating) and under or overcharging.

6. Run your machines to look for error warnings

Rodents love to chew on wiring. An error warning that comes on in the spring that did not appear in the fall might indicate rodent damage.

7. Replace belts and hoses

If belts and hoses weren’t changed in the fall, check for any cracks or damage that may cause larger problems after planting begins.

8. Carefully raise equipment

This can ensure that settling during storage, or other nearby equipment, did not interfere with a machine’s movement.

9. Check the health of your tires

To ensure efficiency, optimal fuel economy and safety in the field requires a tire check. Check the tires for proper air pressure and wear. Be sure to reference your owner’s manual for recommended psi.

10. Make safety a priority

As always, find the time for a good safety check on your machines to ensure everything is in a safe, working condition. Look for any cracked lenses, burned-out bulbs or warning lights, and inspect for missing or damaged shields, warning decals and slow-moving vehicle emblems. ![]()

Jennifer Reibel is with New Holland Parts & Service.

PHOTO: Check equipment for clogged grease points or lack of grease on moving parts and joints that can cause accelerated rate wear and premature failure. Staff photo.