Final yield can vary dramatically on the basis of plant populations in the field, so it is best to plant adequate seeds to ensure the final plant stand is optimum for desired yield.

Obtaining optimum yield depends on how you prepare and set your planter. Adjusting planters to plant a specified number of seeds per foot of row is important in obtaining a proper stand.

Below is a checklist growers should run through to ensure the best stand for any crop. Planters should be checked from the safety chain to row-drive units. It is suggested to:

1. Check the drive trains; make sure they are not rusted or stiff.

2. Check the shaft bearings and sprocket bearings for their shape and condition. They should be well lubricated.

3. Clean and inspect the chemical meters used for seed treatments on the planter.

4. Check the opener blades; make sure they are not worn.

5. Check the sprocket teeth for wear.

6. If equipped, make sure the vacuum meter system is clean and seals are not worn to ensure proper metering.

7. Use the owner’s manual extensively for calibration.

8. Follow all hourly service requirements and greasing requirements.

9. Stop by the dealer or visit the equipment manufacturer’s website to learn what is new.

10. In the field, dig to expose seeds in the row to be sure the planter is operating correctly. This may help avoid an erratic stand after emergence.Confirm desired seed depth and seed-to-soil contact.

Setting a planter for desired planting rate

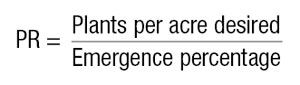

The first step in setting the planter is to determine the planting rate (PR). It can be calculated by the following equation:

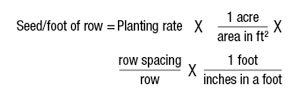

Seed per foot of row required for planting

Next, convert the planting rate to reflect the row spacing in use. An acre of land is equivalent to 43,560 square feet (ft2).

Note: Count seeds in a minimum of 10 feet of row and take the average to ensure the planting rate is as desired. Check a few rows.

Amount of seeds required

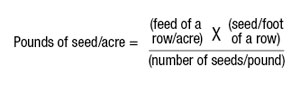

To determine the total weight of seeds needed for planting the whole field, it is essential to know the approximate weight of seed required per acre. The weight of seed per acre required will be determined based on the desired plant population, seed germination and seed size.

For many crops, size and germination rate vary considerably. Therefore, it would not be wise to depend on the same number of pounds per acre each year. The result could be thick or thin stands.

Most seed companies provide information on seeds per pound. If you want to confirm the seed size, count the number of seeds in one ounce of seed and multiply by 16 to get the average per pound. To get a better estimate, check several bags.

To calculate the approximate pounds of seed per acre, use the following formula:

Pneumatic planters (air or vacuum)

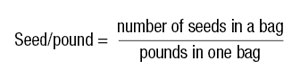

Seed weight for each seed lot can be calculated using the following formula:

Seed companies provide information on the number of seeds per bag and weight of the bag on the seed bag itself or on the seed tag. Knowing correct pressure (air or vacuum) for the calculated seed weight is essential and can be found in the operations manual of the planter.

Correct seed disc (or drum) selection for the calculated seed weight or size is crucial in getting the right work done. Keeping a logbook record of the seed weight and disc number makes it handy to recall procedures. Using the planter’s operations manual, select a correct transmission setting for the desired seeding rate.

Calibrate actual seed drop with the planter transmission settings and the planter monitor readouts. Calibration is recommended at normal planting speeds and seeding rates under as close to field conditions as possible.

Simultaneous calibration of any pesticide and fertilizer planter attachments would be a good idea.

Application rates are subject to change from year to year. Use the correct calibration cup for pesticides. The planter toolbar needs to be parallel to the soil surface when the planter is in the ground and running. Otherwise, it will affect disc opener depth, press wheel efficiency and the adequacy of seed-to-soil contact.

Other issues

1. No-tillage planting: The seeding rate calculations presented above assumed conventional seedbed preparation. In case of planting without seedbed preparation (no-tillage) for small grains or other crop stubble, increasing the suggested seeding rates 10 to 15 percent is recommended.

2. Factors affecting stands:

- Soil conditions – Cloddy, crusted or dry soil may reduce emergence. The desired soil temperature should be 68 degrees to 90 degrees Fahrenheit at the intended planting depth for fast germination and a high rate of emergence.

- Seed treatment – Fungicides may increase emergence of lower-quality seed.

- Depth of planting – Planting depths may depend upon soil type and the existing moisture situation. Deeper planting slows emergence and may reduce final stands. Seeds need to be placed in firm, moist soil and covered adequately.

- Herbicides – Many herbicides can affect stand and seedling vigor in cases of excessive application rates or excessive rainfall.

- Cultivation – Cultivation in furrows (between rows) will not affect stands. Rotary hoes are useful in breaking soil crusts and in small weed removal, but in the morning hours as the seedlings are brittle, stand loss may occur. Care should be taken to avoid stand loss.

- Planting speed – Most planters do a much better job if they are not operated too fast. Read the operator’s manual carefully to determine the suggested maximum speed.

3. Replanting decision: The decision to replant or to keep a partial stand is dependent on the costs associated with replanting, estimated yield improvement, effects of later planting, uniformity of the partial stand, weed control and the physical condition of the remaining plants. FG

—Excerpts from University of Arkansas Extension website

PHOTO

Adjusting planters to plant a specified number of seeds per foot of row is important in obtaining a proper stand. Photo courtesy of Subodh Kulkarni.

Subodh Kulkarni

Program Associate

Division of Agriculture University of Arkansas