Using a disc mower or disc mower conditioner will vary primarily based on what region of the U.S. you are located in, what type of crop you are harvesting and how you are planning to harvest it (i.e., haylage, baleage, dry hay).

Disc mower

The two primary reasons for using a disc mower are:

1. A conditioning system isn’t needed to dry the crop down.

2. You are trying to make hay-in-a-day (high-moisture harvesting).

A disc mower is simply a cutterbar that cuts the crop and leaves it in a swath of about 75 to 90 percent of the cut width. The disc mower is typically used in the central and southern U.S. where tough grasses are the main hay crop and operators choose not to condition their crop due to the climate.

More recently, producers are starting to bale directly behind the disc mower (or mower conditioner) to make baleage. The disc mower is also used by large dairies that cut hay (typically alfalfa or winter forage such as wheat) and then merge it before chopping, all in 24 hours or less.

A disc mower is an economical machine from the standpoint of its price in comparison to a disc mower conditioner, and it also requires less horsepower, using less fuel.

If the disc blades become worn to the point where the blade length is shortened, they will not cut cleanly. Worn blades also require more power from the tractor to operate the machine, increasing fuel consumption.

If the blades are reversible, be sure to use both sides of the blade to avoid unnecessary repair or replacement expenses. When checking the blades, this is a good time to check all the blade bolts and nuts to make sure they are still safe to use.

Also, check the discs themselves for any signs of wear and replace them as needed according to the operator’s manual.

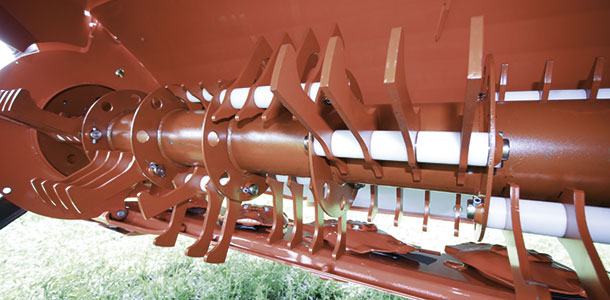

Disc mower conditioner

A disc mower conditioner utilizes a similar cutterbar to the disc mower, but in addition, the crop is conditioned by either fingers or rollers and can be formed into various widths of swaths. Disc mower conditioners are typically used in areas where it is more difficult to get the crop to dry down quickly or where a narrower swath is desired.

A disc mower conditioner can be used to make hay that is wet, dry or anywhere between. There are three common types of conditioning systems – fingers, rubber rollers and steel rollers.

Finger conditioning systems condition the hay by removing the waxy cuticle layer on the stem of the crop. In the past, the finger system was used mostly for grass crops, but with recent advancements, manufacturers have introduced finger systems that can be used in almost all types of crops.

If the finger conditioning system comes with variable speeds, you should condition grass hay at the higher speed (usually 1,000 rpm) and condition legume hay at the lower speed (around 750 rpm) to prevent leaf damage.

If the finger conditioning system has a conditioning hood, this will need to be adjusted based on crop type and density. The closer the hood gets to the fingers, the more intense the conditioning will be.

With legume crops, you will want the conditioning hood to be opened more unless it is a very light crop. It’s also important to take time to adjust a finger machine based on your crop type, crop density and your planned form of harvest to ensure the highest-quality hay possible.

Rubber and steel rollers are very similar in concept and are more prevalent with legume crops because of their more gentle and forgiving nature.

The intention with conditioning rolls is to crimp the crop, allowing moisture to wick out at the crimp points and dry as quickly as possible. Roll gap spacing is important because if the rolls are too close together, they can cause unnecessary leaf damage and can plug in denser crop conditions.

If the rolls are too far apart, little or no conditioning will take place and will ultimately slow drying time. Roll pressure is also very important for optimal drydown. Pressure should be adjusted for each crop and each cutting to achieve maximum drydown.

The cutting height with either a disc mower or disc mower conditioner is important based on the type of crop, the field conditions and what you want to achieve.

The higher the crop is cut, the less soil or ash incorporation, drying time is increased as a result of more air movement, and we gain better regrowth for the next cutting.

Generally, legumes should be cut around 2 inches, and grass hay should be cut around 4 inches high. The disadvantage to a higher cut height is that you will ultimately get slightly less tonnage per acre. One additional reason for a higher cutting height is to avoid rocks.

Selecting the proper machine for your operation is imperative to harvesting high-quality forages. If you choose a disc mower conditioner, make sure to select the correct type of conditioner and to adjust it properly. Be sure the machine is cutting at the appropriate height and all components are in good working order for maximum efficiency. FG

Ryan Miesen is a product specialist with Kuhn North America Hay Tools.

PHOTOS

Disc mowers and mower conditioners need to be adjusted for cutting height and roll gap to achieve best-quality forage harvest. Photos courtesy of Ryan Miesen.