Early in my high-school career my ag-science teacher, Trent Houchin, and I were in a pasture checking my cows and discussing options for involvement in FFA, and I was really intrigued by the thought of designing and building my vision.

So the journey began on building the hydraulic pickup-bed hay spears.

The basic concept was to implement what I already had available in my pickup to assist in hauling and handling hay.

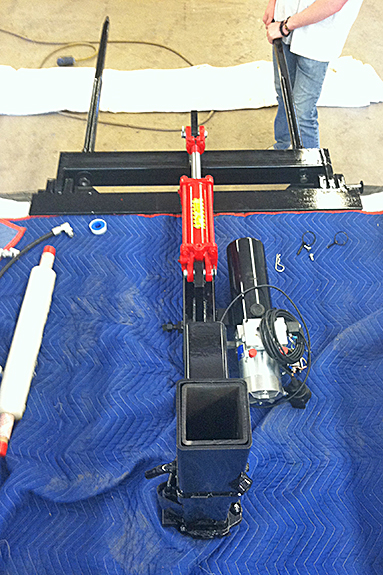

I decided to use the gooseneck ball as the main anchor and somehow hook up a hydraulic pump to my battery, and a hydraulic cylinder to extend and retract the forks from the pickup bed. I spent three months from initial design to the final project.

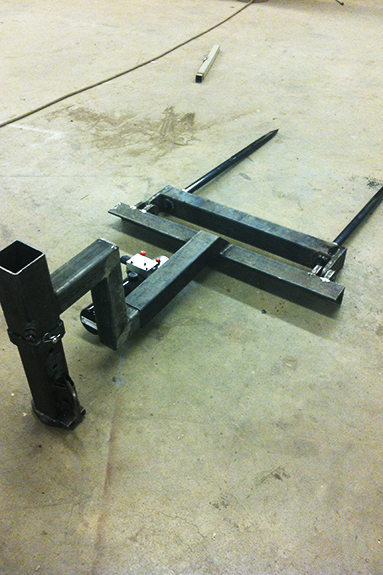

As this was my first major building project, I decided to build a ‘decoy’ and learn from my mistakes.

After completing the decoy, I had two minor adjustments to make, the first being the placement of the 1-inch plate used for anchors, and the other being the distance between the hitch and the telescoping body.

The main structure was made of 4-inch by 4-inch square tubing that would telescope in and out to allow adjustments for both long-bed and short-bed pickups.

The main power source comes from a 12-volt hydraulic pump with leads to the battery. Along with the main structure, a neck was constructed to resemble a gooseneck-trailer hitch to use leverage from pulling on the ball and the strength of the pickup bed to bear the weight.

I decided to have it hook to the ball instead of the conventional bolt-to-frame design for ease of installation and removal in order to open up the bed for everyday use.

The weakness of the design is that is limited to the vehicle in which it is mounted. While the complete unit weighs just over 200 pounds, it becomes really clear that hauling the spears and the hay bales is quite a task that requires a heavier-duty pickup.

I recently sold one of the units to a local farmer-rancher who uses it often and says it’s a great and efficient way to haul single bales to small herds without the hassle of a tractor.

While this project is not patented it is important to remember that many factors are to be considered when building custom equipment like this.

I owe tons of credit to the local machine shop, my agri-science instructor and people in the community for their help, big or small, in my project. FG

Note: Zepplin Smith took fourth place for his design at the San Antonio Livestock 2013 show in the Agricultural Machinery and Equipment Division – hay handling equipment class. He can be contacted by emailing his ag science instructor, Trent Houchin.