Note the term “hay-making system” is purposefully used. This is because each piece of equipment (e.g., mower, tedder, rake, baler) needs to match the size and field efficiency of the other pieces of hay-making equipment.

Even if just one piece is not as efficient as the others, it can create a bottleneck. This can increase rain-damage risk, lower hay quality and increase per-ton cost.

One of the most important considerations in any purchase is the price. The farm owner or manager, with the assistance of one’s extension educator as needed, can determine what an individual farm should be able to afford. Each farm is different.

Nonetheless, generalizations can be made as to what will minimize the number of man-hours required to make the amount of hay required.

The first step is to get a handle on the amount of hay needed.

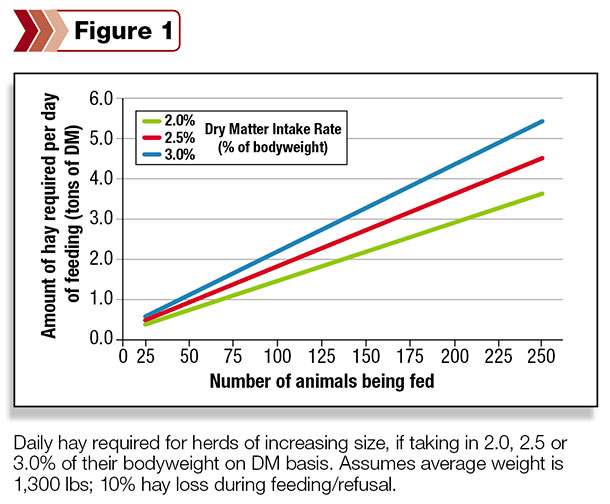

Figure 1 shows how much hay is needed for each day of feeding based on herd size. Once the amount is determined, the number of hay acres can be estimated.

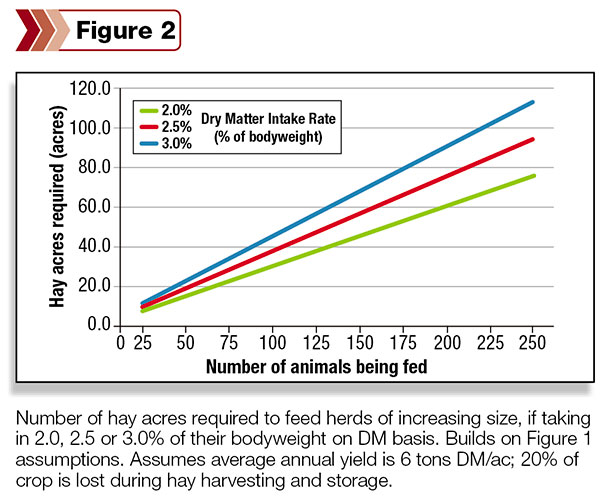

Figure 2 uses estimates from Figure 1 and provides an estimate of hay acres needed. For example, 100 head of 1,300-pound beef cows that eat approximately 2.5 percent of their bodyweight will need about 1.8 tons of hay each day. If feeding for 100 days, 180 tons of hay will be needed.

Assuming fields yield 6 tons of dry matter per acre (five cuttings per year), and there is 20 percent loss during harvest and storage, this will require at least 38 acres of hay production.

Once it is determined how many acres must be harvested and how many cuttings are necessary, comparisons of field efficiency need to be considered.

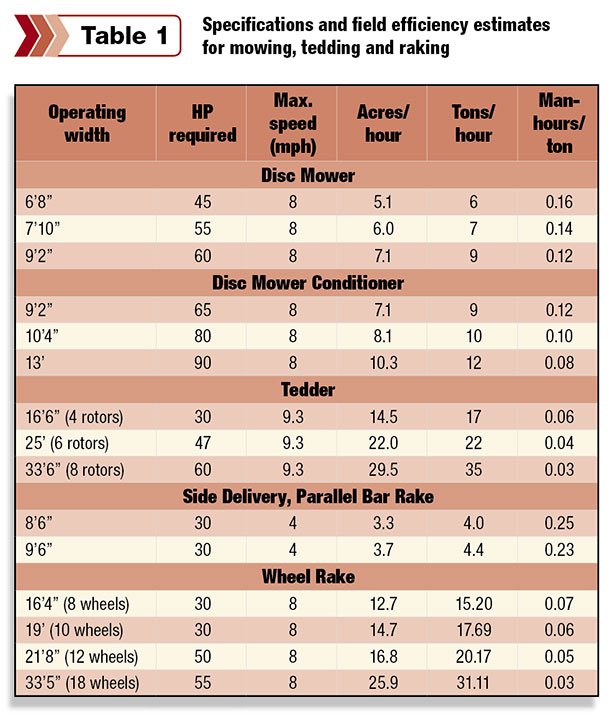

Table 1 provides estimates of field efficiency for different equipment in the cutting, tedding and raking portions of the hay-making system.

When dealing with cutting, tedding and raking, efficiency is determined in acres per hour. Hay baling depends primarily on the raking step to ensure a sufficiently sized windrow that allows the baler to function efficiently.

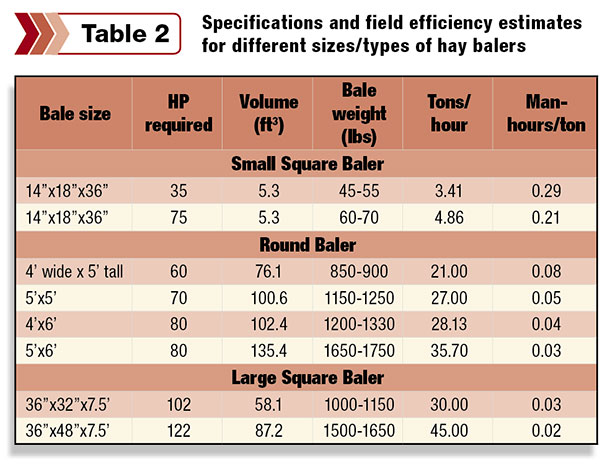

Thus, when comparing efficiency of baler options, focus on tons of hay baled per hour.

Table 2 provides estimates of field efficiency for baler types.

Recall that to obtain hay needed for a 100-day feeding period, five cuttings per year on 38 acres are needed. Let’s assume a 6-foot-8-inch disc mower (no conditioner), a 16-foot-6-inch tedder used the afternoon after cutting and again the next morning (two passes per cutting), an 8-foot-6-inch side delivery/parallel bar rake and a round baler that makes 4-foot-wide and 5-foot-tall bales are used.

Using Tables 1 and 2, we can determine about 132 man-hours per year are needed (about 26.4 hours per cutting). Now let’s assume the purchase of a 10-foot-4-inch disc mower-conditioner, a 25-foot tedder (two passes per cutting), a 19-foot wheel rake and a 4-foot-by-6-foot baler are being considered.

Again using Tables 1 and 2, we can estimate that the labor requirement is reduced to less than 62 man-hours per year (about 12.4 hours per cutting), which is more than a 50 percent reduction in man-hours.

This is an extreme example. It has been a decent year for profitability, but it hasn’t been so great as to provide enough money to buy all-new hay equipment. Usually, producers will change one or two elements at a time. In this case, the biggest efficiency improvement was made with the large wheel rake (78 percent less time).

But all changes in equipment size made for significant time savings. Though changing to a larger baler had the smallest labor-saving effect, it is worth pointing out that the time spent baling is often the time when hay is at greatest risk of being rain damaged.

Though these field efficiency values are estimates, they can be useful in comparing equipment. Before making an investment in a new piece of hay-making equipment, do more than look at the price tag. In addition to its cost, consider how the implement will fit in your system, whether or not it will match your other equipment and its potential to save time. FG

—Reprinted from Midwest Forage Association’s Forage Focus

- Dennis Hancock

- Assistant Professor – Extension Forages

- University of Georgia