And then, likely, producers talk – with a sigh – of new chute designs and all that metal, lumber, labor and time that it would take to convert the old alleys and chutes to better facilities. But Grandin says you can start now, with what you have, and making even small, low-cost changes will ease livestock movement and reduce animal stress.

Speaking at the 2015 American Forage and Grassland Council annual conference in St. Louis, Missouri, Grandin presented a list of visual items that can easily be corrected in most facilities.

Light

Animals refuse to move into a flaming sun or really bright light (which is like asking a person to drive toward an intense sunset without a visor). Conversely, cattle are equally reluctant moving into very dark places, like a darkened barn door when it’s bright outside. Grandin recommended the use of translucent panels in the barn structure to allow natural daylight to penetrate a facility and equalize illumination. At the very least, when trying to move cattle indoors, if a few barn doors are simply opened, even that action will allow some light into a building, which makes an animal more likely to enter.

Blowing or fluttering distractions

It’s a common site at livestock facilities to see a coat hanging from a post. Grandin said even small breezes causing a coat to shift will result in cattle that balk at approach. She related a visit she took to a packing yard where she assessed loading facilities and found something as small as a paper towel blowing in the wind on an alleyway that was causing cattle to refuse to enter.

Another common item that producers tend to overlook is a chain hanging down in the chute or a jiggling chute gate – each requiring only minimal attention to correct. Grandin encouraged producers to be aware of visual cues for cattle, to become better observers of what the cow sees, cautioning that anything unfamiliar to the animal will become an obstruction to animal movement.

Cattle handling facilities for a lot of producers are filled with commotion. Grandin said, “Get rid of dogs at corrals; it teaches cows to kick,” and, “Don’t invite everybody and his mother to the party.” She emphasized that increased commotion, yelling, whistling and screaming is stressful to livestock and measurable cortisol levels in cattle will rise under stress. “We've got to calm down,” said Grandin. “Cattle that are upset stick together and bunch up, and it takes twice as long to work them.”

New objects

When cattle approach something new, they’re quite curious. If given time, cattle will slowly, voluntarily approach the new area. Cattle have only wide-angle vision, so it is necessary for them to put their heads down to familiarize themselves with something new, like a puddle. However, if the leader cow is given time, she will approach the puddle, put her head down and then step into it. At that point, the other cattle will follow.

However, Grandin said most livestock handlers always want to crowd and push cattle, which essentially has the opposite effect – causing cattle to resist movement.

“People think they’re toothpicks and should fit in there nice and tight, but they’re not,” said Grandin. By the same principle, Grandin encouraged producers to fill crowd pens only half full instead of trying to squeeze the pen tight. If producers change the timing in the chute and work smaller groups of cattle, the cattle will be calmer and flow better.

Grandin also said cattle must acclimate visually to handlers. For instance, a man on a horse presents a different visual than a man on foot. Cattle will move more smoothly if they are familiar with the visual, so it may be necessary to work with range cattle on foot before sending them to the feedyard, or get them comfortable with a man on a horse if that will be the primary method of movement in the future.

Flight zone

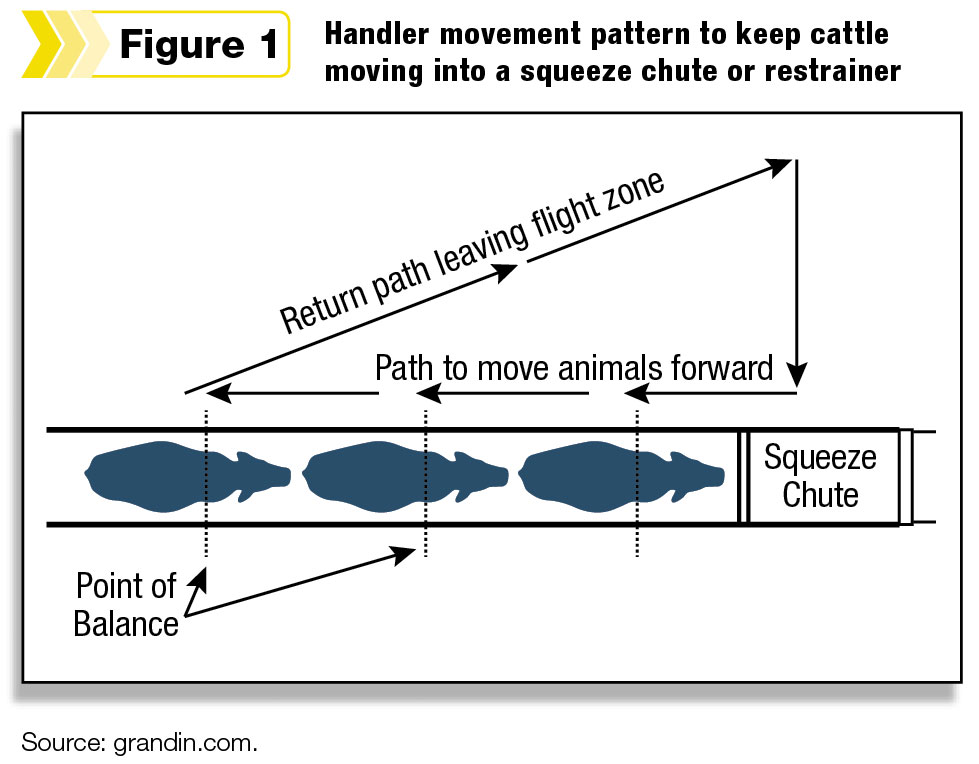

An animal’s flight zone is its safety zone. If you enter an animal’s flight zone, it will move away. Approaching an animal from the front and passing an animal’s shoulder moves the handler into the flight zone, and cattle will move away from the handler. Thus, the movement is counter-intuitive to humans whereby animals move away from the handler not by having the handler push them from behind, but by crossing from the front of an animal into the animal’s flight zone (see Figure 1).

Warning signs that cattle are uneasy or fearful include: Heads up and ears alert, ears pinned back, defecation, tail switching and eye whites showing. Sometimes cattle will rear in the chute, as well. All of these behaviors indicate humans are in the animal’s flight zone. It’s simple – if this happens, Grandin says, “Get out of its flight zone.”

Quick facility fixes

Grandin also suggested that one fairly quick and inexpensive fix to facilities is to install non-slip flooring, which can be achieved by securing tire rubber to the floors of chutes or alleyways. An animal that slips quickly becomes stressed and resistant to fluid movement.

Another quick fix is to use a piece of cardboard on the back half of a squeeze chute to block the animal’s vision of a worker standing nearby. Even thin plywood secured to the outer edge of a chute or alleyway to block visual distractions can be helpful to move cattle more fluidly.

Measure improvement

“We measure everything else,” Grandin said. “Why not handling?” Handling, she maintains, is observable and measureable. For instance, when working cattle, Grandin suggested having someone keep track of things, like how many cattle ran through the chutes, how many fell down during handling or stumbled while exiting, how many reared in the chute and how many were defecating in the chute. Tracking these indicators lets a team know how they’re doing and what needs improvement.

Selecting for temperament

Producers have been selecting for better temperament for at least 20 years, through the use of EPDs, but Grandin recommends caution with this approach. “I’m getting concerned for temperament selection. We don’t want beef cows to become like Holsteins, for instance, walking away from their calves with no ‘fight’ in them for mothering.” She emphasized that EPDs are a powerful tool but could backfire with unintended consequences.

Grandin noted that one of the biggest problems on the rise among cattle is lameness, and in a recent show catalog only 19 percent of the stock pictures had hooves showing (thanks to Photoshop’s ability to cover them with grass), likely because of a genetic problem with lameness. While there are many contributors to lameness – such as scuffing hooves when agitated, rapid growth and poor foot care – one contributor to the problem is EPD selection for traits that did not address poor leg conformation. Grandin said she fears additional issues may surface among cattle when over-selecting for temperament.

Grandin said expensive facilities with good designs are certainly easier for unskilled people to use, and simple, economical designs require more stockmanship skills. But even small facility improvements can make a big difference in efficiency and animal flow. Grandin concluded, “Most producers will say they don’t have time for calm handling, but ‘slow’ is ‘fast.’” FG

Visit Temple Grandin’s website to see facility designs and other animal handling tips.

Read more about the 2015 American Forage and Grassland Council annual conference.

PHOTO

Temple Grandin addresses livestock handling techniques at the 2015 American Forage and Grassland Council conference in St. Louis, Missouri. Photo by Lynn Jaynes.