Many dairy farmers rely increasingly on corn silage to meet forage needs. While the efficiencies associated with the production, harvest and storage of corn silage are attractive, a less desirable corollary of this management trend is the increased linkage of manure distribution with production of corn.

Specifically, manure distribution is restricted to time intervals before spring planting or after fall harvest. It is widely realized that both of these opportunities can be affected seriously by wet weather conditions throughout much of the U.S.

The need for more diversified cropping systems that create additional hauling opportunities throughout the summer months has been widely recognized.

Within that context, dairy producers periodically enquire about the potential risks of applying dairy slurry on alfalfa fields during summer months. Usually, these inquiries occur when manure-storage reservoirs are approaching capacity and there is an urgent need to avoid a potential environmental accident, although some dairy producers apply dairy slurry on alfalfa routinely.

Primarily through on-farm observations, a number of potential problems have been identified with this management practice, including salt or ammonium burn to fragile alfalfa regrowth, smothering of alfalfa plants as a result of excessive manure application rates or damage from spreader-wheel traffic.

Some states have provided guidelines for avoiding these problems through various extension outlets and resources.

Wheel-traffic damage to alfalfa forages following applications of dairy slurry. Photos courtesy of Wayne Coblentz.

Wheel-traffic damage to alfalfa forages following applications of dairy slurry. Photos courtesy of Wayne Coblentz.

Another problem linked with manure application that has received much less attention is the potential inoculation of alfalfa silage with undesirable micro-organisms, such as clostridia.

Most research of this type has been conducted in northern Europe with direct-cut, wet, cool-season grasses. Typically, clostridial silages can be identified by a greater (less acidic) final pH and greater production of ammonia and butyric acid than occurs normally in most silages.

Alfalfa is especially sensitive to clostridial fermentations because it has limited concentrations of the water-soluble carbohydrates (4 to 7 percent) needed as substrate during silage fermentation and a very high buffering capacity. In simplest terms, buffering capacity can be described as the natural, inherent resistance to pH change.

The overall goal of silage fermentation is to rapidly reduce the pH, which contributes to silage stability; for alfalfa, high resistance to pH change makes the “queen of forages” difficult to ensile compared to forages with low buffering capacities, such as corn.

From a livestock perspective, clostridial silages often are consumed very poorly, and in extreme cases, can only be redistributed on fields, essentially as manure.

Experiment at Marshfield

To evaluate the potential for clostridial fermentations following applications of dairy slurry on growing alfalfa, scientists at the U.S. Dairy Forage Research Center (USDA Agricultural Research Service), the University of Wisconsin and the University of Arkansas conducted an experiment during the summer of 2012 at the University of Wisconsin Marshfield Agricultural Research Station (Stratford, Wisconsin).

Sixteen 0.41-acre plots (45 × 400 feet) were established in an existing alfalfa field such that dairy slurry could be applied (broadcast) with field-scale equipment. Four treatments were evaluated: no slurry (control), slurry applied to alfalfa stubble immediately after the preceding harvest, slurry applied after one week of alfalfa regrowth or slurry applied after two weeks of alfalfa regrowth.

Slurry was applied after the first cutting was removed, and the treatments were applied a second time after removal of the second cutting. Alfalfa was ensiled in large square bales wrapped in plastic stretch film and stored on a concrete pad until May 2013, when silage samples were obtained for final analysis.

Results

Generally, the application of dairy slurry had little effect on yield, nutritive value or the fermentation characteristics of the alfalfa baleage. Overall, the recovery of dry matter from these baled silages was reasonable for this ensiling technique (96 percent).

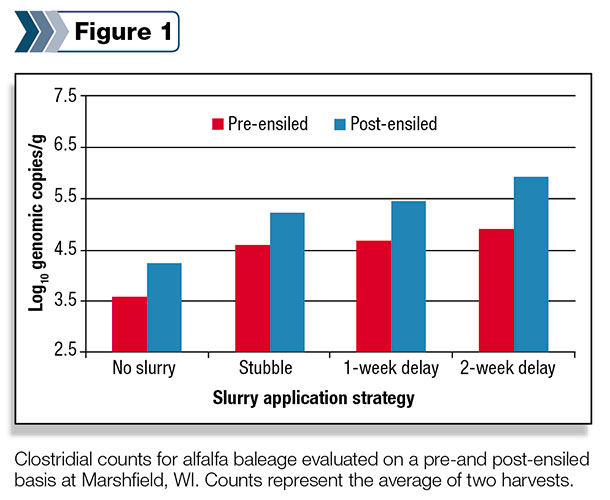

The most intriguing aspect of the study was the clostridial bacteria counts (Figure 1). This figure represents responses to slurry application treatments averaged over two harvests, and there are several key points that can be gleaned from this illustration.

First, there are significant numbers of clostridia adhered to alfalfa forages, even when no slurry is applied. This is not surprising and supports common extension recommendations to avoid inoculating alfalfa silages with dirt from raking or other field operations during harvest.

Secondly, clostridial counts were greater any time slurry was applied compared to no slurry, and this was true on both a pre- and post-ensiled basis, regardless of timing.

Furthermore, counts generally increased as application was delayed, with the greatest counts occurring when application was delayed for two weeks following the previous harvest.

Finally, counts were always greater on a post-ensiled compared to a pre-ensiled basis. In assessing these data, it also is important to remember that clostridial counts are normally presented on a log scale, where a score of 3 is equivalent to 1,000 genomic copies per g, while a score of 6 is equal to 1,000,000 genomic copies per g.

No Clostridium tyrobutyricum, which has been linked with “late-blowing” during cheese production, was detected within the applied dairy slurry or in any alfalfa baleage.

Recommendations

Based on very limited research, the following recommendations can be made.

1. Risks of clostridial fermentations within alfalfa silages are greater whenever dairy slurry is applied; however, risks are reduced when the slurry is applied directly to stubble compared to delayed applications on growing plants.

2. Within this study, the use of baleage techniques that require a reduced moisture concentration compared to precision-chopped silages likely limited the potential for clostridial fermentations.

Reducing moisture concentrations by field wilting is a common recommendation for avoiding clostridial fermentations in precision-chopped silages. As a general management practice, it may be prudent to consider some additional field wilting (perhaps to a 55 to 60 percent moisture target) relative to traditional recommendations for precision-chopped silages (70 percent or less) whenever dairy slurry is applied. Additional work is needed with chopped silages to verify this recommendation.

3. A silage inoculant that supports production of lactic acid should be used whenever dairy slurry is applied to alfalfa stubble or regrowth.

4. Within this study, we did not attempt to assess salt or ammonium burn, smothering or wheel damage to alfalfa plants. However, visual observations suggest that these can be potential problems, and slurry should only be applied to alfalfa stubble.

Any applications of dairy slurry on growing alfalfa plants should be viewed only as a last-management option. If delayed applications are absolutely necessary, select an old stand instead of risking damage to recently established plants.