Good management can limit leaf loss by maximizing drying rate, raking at or above 40 percent moisture, adding moisture in overly dry conditions and machinery adjustment.

Mowing/conditioners

One of the best ways to get hay to dry faster is to spread it wider and thinner. This will rapidly dry the first 15 percent moisture off, minimizing starch and sugar loss. Failure to do so will result in a 2 to 8 percent starch and sugar loss, which will cause a 7- to 30-point drop in relative feed value.

Conditioning is important for stem drying and water loss below 50 percent moisture. Alfalfa has a waxy outer layer to hold water in while the plant is growing. When alfalfa is cut, the wax increases drying time because water cannot escape.

Conditioning alfalfa cracks and breaks the stems and, if adjusted correctly to have about 5 percent leaf bruising, should not cause much damage to the leaves. When the plant dries faster, it can get baled faster.

Rake

Some regions need hay to dry fast to avoid being rained on; all regions need hay to dry fast to minimize wheel traffic damage to the next crop. When alfalfa starts to regrow after mowing, before the hay is chopped or baled, harvesting wheel traffic can break stems and reduce later plant regrowth and crop yield. If the hay can be raked and baled up before plant regrowth occurs, then yields are less affected by wheel traffic damage.

Most people do not make proper adjustments on their hay-making equipment to minimize damage to alfalfa. This is a crucial step in the hay-making process because it can mean the difference between picking everything up or leaving hay behind, or causing too much damage.

Additionally, make sure to form uniform windrows so hay can dry as evenly as possible, thus minimizing leaf loss.

Wheel rake

This is the least expensive rake and can have the largest swath width. A wheel rake is better for drier crops because it is powered by forward movement of the tractor instead of the power take-off (PTO) or hydraulics. This rake should be adjusted to have minimal soil contact to turn the wheel.

Changing the weight carried on the wheel changes pressure on the tines: too light and hay is left behind, too heavy and the teeth kick more soil and stones into the hay and bend or wear faster. Wheel rakes have the tendency to “rope” hay after the raking operation, which can reduce air movement through the windrow and slow the drying rate.

Parallel bar

The smallest of the available rakes, parallel bar rakes with either single frame or twin frames, are declining in popularity due to size limitations. Parallel-bar rakes also have a power train and many moving parts to maintain. This rake is driven by the rubber tires, PTO or hydraulics, so tines need not touch the ground.

This gives this rake type sufficient power to handle wet, heavy swaths or windrows. However, the parallel bars will drag tines across ridges in the field. This is a particularly a problem in non-level fields where some hay in valleys is missed and, when hitting a ridge, more dirt will be picked up.

Rotary rake

The rotary rake also is PTO or hydraulically driven and can handle wet, heavy swaths. The two primary features that differentiate these rakes are the rotor diameter and the number of arms. Larger-diameter rotors will improve the swath width handled, and more arms will increase the capacity. Rotary rakes tend to make a well-formed, less-roped windrow that allows good air circulation and good crop drying.

This machine should be adjusted so the tines do not come in contact with the ground to prevent incorporating rocks or soil in the hay and to prevent premature wearing of the tines. The correct combination of tractor gear and engine speed must be found so that leaves are not separated from stems and thrown from the machine.

Hay merger

While technically not a rake, mergers pick up hay and move it on a conveyor without dragging along the ground. Hay mergers are the most expensive of tools for merging swaths, but they have the lowest leaf loss. Mergers should be sized so the resulting windrow will be smaller than the pickup on the baler or chopper.

Hay-making conditions

Although we cannot control the sun, rain or temperature (even though we all wish we could), we can optimize hay drying for conditions we do have. Sometimes this requires extra steps, but always plan to move cut hay as little as possible.

Remember that additional operations, such as windrow inverting or tedding, may increase drying time slightly, but each handling prior to baling results in leaf loss, reducing dry matter and forage quality harvested. Preparing hay so that there is the least amount of handling will help with keeping leaf percentages high.

Putting hay into wide swaths when cutting will help hay dry faster and more evenly. Sun-exposed surface hay of a windrow dries faster than the interior of the windrow. When moisture falls below 20 percent, extreme leaf loss is prone, even during the baling process.

Another thing one can do, when hay gets too dry, is to use a machine to add moisture or to bale at night after the dew has set. Either option can raise moisture enough that leaf loss will not be as prominent.

Before purchasing a rake or windrow merger, it is important to consider the compatibility of the mower-conditioner width, merger pick-up width and the forage harvester or baler pick-up width.

One should consider the ability of the rake or merger to pick up hay: for example, does the hay in the swath lay parallel to the direction of cut or at an angle? If hay lays perpendicular to the direction of cut, then the rake or merger tines must move at an angle to pick it up. Also consider matching wheel tracks to minimize traffic damage to the next growth.

Conclusions

High-quality hay production considers the following factors:

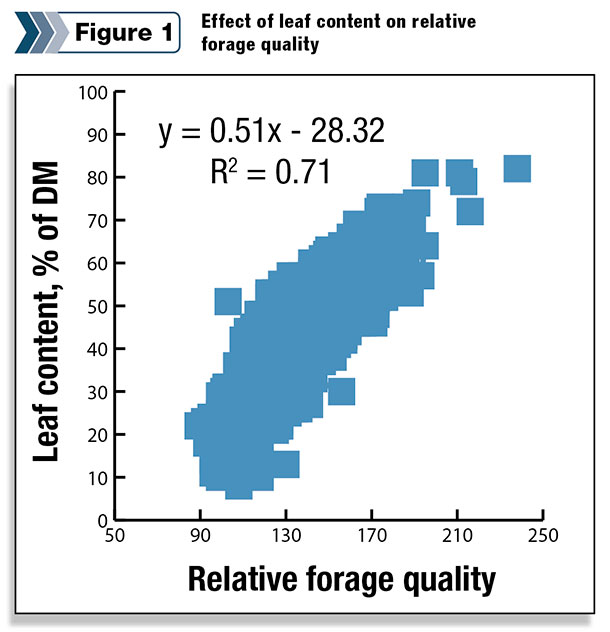

- Leaves are more digestible than stems.

- RFQ is highly related to the percentage of leaves in the hay.

- Conditioning hay will help swaths or windrows dry more evenly.

- Adjust your rake so that it will move the windrow but not throw or damage leaves.

- If hay is too dry, add moisture or bale after the dew has settled to prevent brittleness and leaf loss.

- Do not use tedders with alfalfa hay, as it can cause extreme leaf loss.

Anna Teeter is a student at University of Wisconsin-Madison with a double major in agronomy and ag communications.

-

Dan Undersander

- Forage Specialist

- University of Wisconsin

- Email Dan Undersander