As they say, necessity is the mother of invention. After years of struggling with costly and time-consuming loading and unloading methods for hay and straw, Jason Grady decided to do something different.

Grady is a third-generation farmer in Farmington, New Mexico, who works with the Navajo Agricultural Products Industry (NAPI), which is the farming and agricultural business operation of the Navajo Nation, the largest Native American tribe in the U.S. NAPI is known for marketing crops and livestock across the country.

His grandfather started the custom hay and straw business, J&M Baling, more than 30 years ago on the same land Grady currently farms. Today, the business caters mostly to the equine sector across the country and is one of the largest forage suppliers to the horse-racing industry.

“Farming is what I know,” says Grady, who started in the family business at 10 years old.

The business started with just three balers and a few trucks and grew to 16 small balers, three Freeman three-tie balers and 13 trucks. As demand for their product grew, so did the time and expense to ship quality products to their customers.

In many parts of the country, forage is strapped to an open drop-deck trailer. This method works for short to medium distances, but for very long distances, it leads to bale damage and waste. Further, the cost to ship is extremely high because drop-deck operators are in higher demand.

“My family is innovative, I was raised to try to create solutions to problems,” Grady says.

It was innovation that first led him to use commercial van trailers – much like any semi on the interstate – to ship forage to his clients.

“There is virtually no waste or damage using van trailers, and it costs usually 30 percent less per mile because the operators are looking for work,” Grady says. “My clients can save up to $1,000 per load from New Mexico to Kentucky using a van trailer.”

But what about loading and unloading the van trailer?

The design for the Grady Press Trailer came to Jason Grady initially in a dream. Photo courtesy of Jason Grady.

The design for the Grady Press Trailer came to Jason Grady initially in a dream. Photo courtesy of Jason Grady.

“It used to take me two-and-a-half hours to load each van trailer, and with 13 in my personal fleet, the labor and time was killing us,” Grady says.

On the receiving end, Grady says that his clients would often unload the van trailers by hand with eight to 10 people. He knew there had to be a better way.

The idea for the press trailer, the founding product for Grady Press Trailers, came to Grady in a dream.

“After a long day in the field, I dreamt that I was operating this machine that used a press to ‘push’ the forage into the van trailer. I woke up in the middle of the night and started sketching. I spent six hours that night perfecting my design,” Grady says. “My wife thought I had lost my mind.”

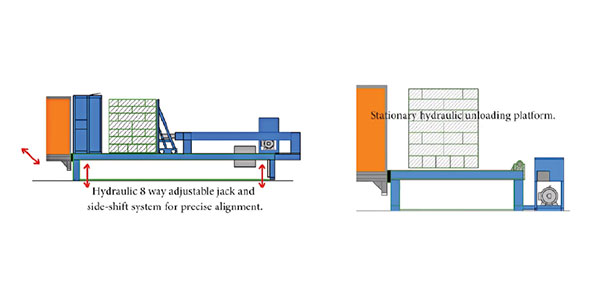

Stationary unloading platform helps customers reduce labor and time with each van trailer of forage received. Platform can also be used for other products. The loading trailer features a hydraulic eight-way adjustable jack and side-shift system for precision alignment. Sketch from Grady Press Trailers website.

Stationary unloading platform helps customers reduce labor and time with each van trailer of forage received. Platform can also be used for other products. The loading trailer features a hydraulic eight-way adjustable jack and side-shift system for precision alignment. Sketch from Grady Press Trailers website.The loading trailer features a hydraulic eight-way adjustable jack and side-shift system for precision alignment. Bales are stacked in the field in cubes of 60. Each cube is lifted onto the press trailer and loaded in to the van for transport. The press trailer can also be used to load international containers.

Grady also designed an unloading trailer that is intended to be a companion product to the press trailer. It features a stationary hydraulic unloading platform that draws bales out of the van on a conveyor. From there, a typical skid steer or tractor can be used to stack bales in customers’ storage areas.

Brooks Nickles owns and operates Williams Bros Feed and has been doing business with J&M Baling for more than 20 years. Williams Bros Feed has been in operation since 1918 and is the largest feed supplier in Hot Springs, Arkansas, and one of the major vendors for the famed Oak Lawn Park racetrack.

Smarty Jones and Zenyatta are just a few of the recognizable racehorses who have spent the winter at Oak Lawn Park and bedded on straw from J&M Baling.

“Oak Lawn Park is where all the major racehorses spend their winters. From November to April, we use about 30 to 35 loads (53-foot commercial van trailer) of straw from J&M Baling,” Nickles says.

The unloading trailer has saved customers like Nickles money and time. Most importantly, the trailer has reduced the “headaches” associated with trying to find employees to unload straw by hand.

Nickles can now unload a van of straw in under an hour. He also uses it to unload feed and hay he gets from other sources.

“I’ve only had the trailer since November of 2013 and already our savings are substantial, and it’s much easier to do business with this trailer,” Nickles says.

“When Jason told me about his idea, I told him it wouldn’t work,” Nickles says. “But the guys at J&M can basically build anything, and I learned that you just don’t tell Jason he can’t do something.”

After Grady made his initial drawings, he approached his father about investing in the project.

“My dad said it was never going to work,” Grady says. “But I convinced him to give the project a shot.”

During the building and testing phases, Grady and his father would not let anyone watch because they were unsure what the results would be. The resulting prototype worked on the first try.

“I wish I had some wild trial-and-error stories from my testing phase, but honestly, it worked the first time we tested it,” he says.

J&M Baling is a long-time Freeman Baler dealer and decided to approach the well-known company to help perfect the design and manufacture the trailer.

“Freeman flew a few representatives to New Mexico to take a look at the prototype. Their design team made a few minor changes, and now the trailer will be manufactured by Freeman under the name ‘Grady Press Trailers by Freeman’,” Grady says.

Freeman Balers serves as the manufacturer, and Grady is responsible for all design and sales. In fact, he’s currently in the midst of the lengthy process of securing a patent.

“The design is ‘patent-pending,’ and the process takes about five years to complete,” he says. “It’s one of the most complicated things I’ve ever had to do.”

This past February, Grady Press Trailers exhibited alongside Freeman Balers at World Ag Expo in Tulare, California.

“The interest was through the roof. People have never seen anything like it before,” he says.

Currently, there are just a handful of Grady Press Trailers in use outside of Grady’s personal fleet. However, the “press trailer” concept is gaining attention and showing promise for additional sectors of agriculture, such as dairy and livestock.

For customers like Nickles, “The [Grady Press] trailer has improved the way we handle forage. It’s a game-changer,” he says.

To learn more about Grady Press Trailers, go to and watch a video of the product on YouTube.